What is a wedge-shaped wire filter?

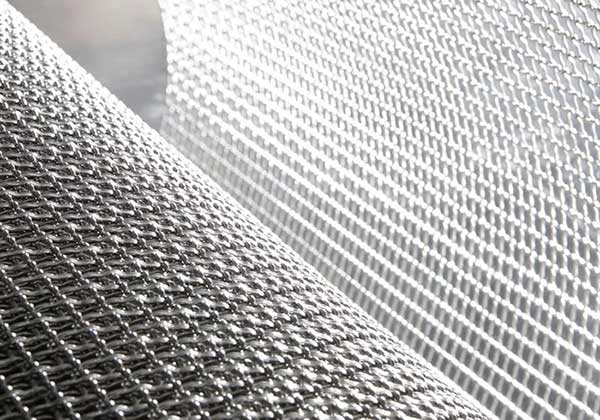

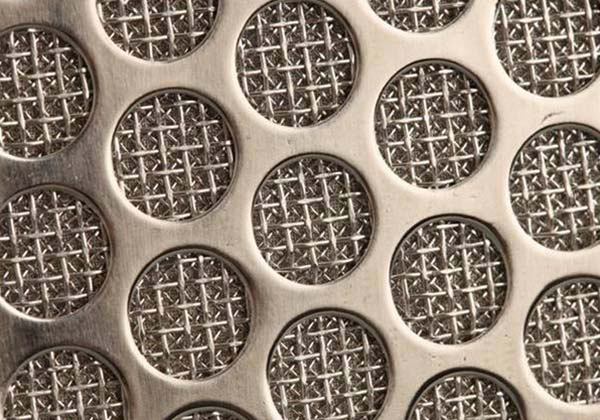

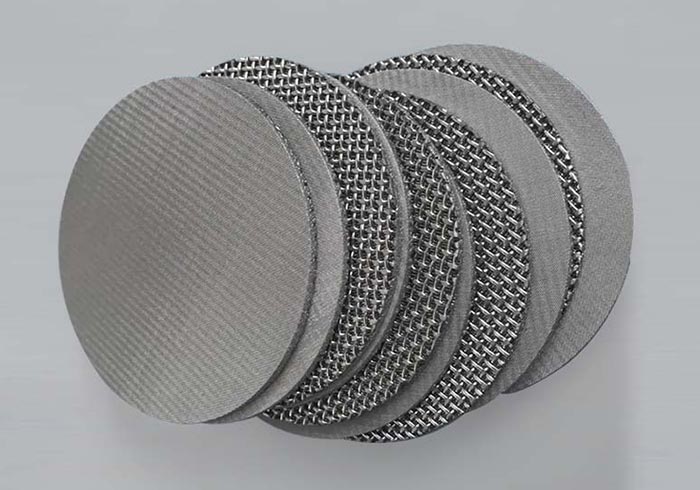

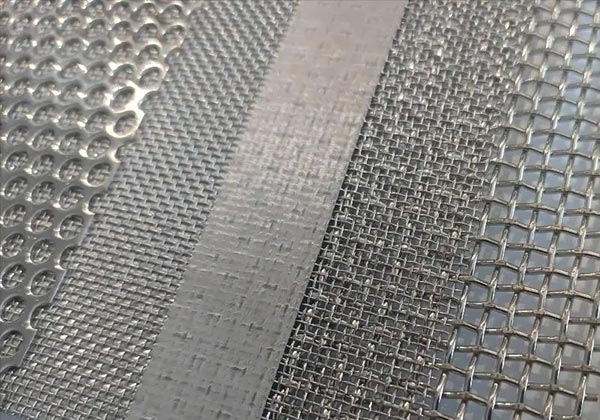

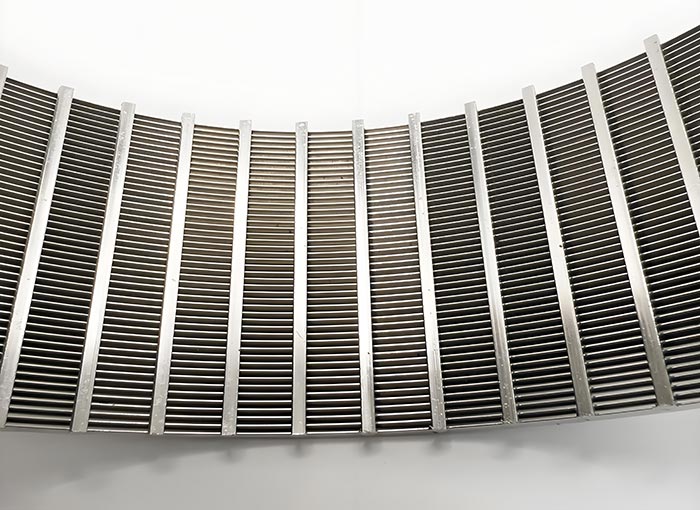

Wedge-shaped wire filter cartridge is a unique filtering element known for its sturdy structure and excellent filtering performance. These filter elements are made of stainless steel and consist of a series of irregular wires that are precisely welded to the support rod, forming a wedge-shaped structure. This unique design can form continuous slit openings, effectively separating particles from the fluid.

The working principle of wedge-shaped wire mesh filter is simple and effective. When fluid flows through the filter, the wedge-shaped opening blocks particles larger than the slot size, while allowing cleaner fluid to pass through. The main features of these filters include high structural strength, excellent accuracy, and the ability to withstand high pressure differentials. This design not only optimizes liquid flow but also minimizes clogging, making wedge-shaped wire mesh filters the preferred choice for many industrial applications.

Advantages and disadvantages of wedge-shaped wire filter

Wedge wire filter cartridges are widely used in industrial filtration, especially for applications where strength and accuracy are crucial. Like any technology, wedge-shaped wire filters have both advantages and limitations. Understanding these advantages and disadvantages will help you determine whether the wedge-shaped wire filter is suitable for your specific application.

Advantage

High strength and durability: The wedge-shaped wire filter can withstand high pressure and abrasive materials. Its welding structure is wear-resistant and not easily deformed, making it an ideal choice for harsh industrial environments.

Precision filtration: The continuous tank design enables precise particle separation, ensuring high product purity. This makes wedge-shaped filters particularly useful in applications where fine filtration is crucial.

Low maintenance cost: The wedge-shaped filter adopts an anti clogging geometric structure, with a low frequency of cleaning or replacement. The open slot design helps prevent fouling and maintain stable flow.

Long term cost-effectiveness: Although the initial cost may be high, its longer lifespan and lower maintenance requirements mean less downtime and better overall return on investment.

Disadvantage

Higher upfront costs: Compared to simpler filter types, wedge-shaped line filters typically have a higher initial price due to their complex manufacturing process.

Very fine filtration has limited flexibility: for ultra fine filtration below certain micron levels, wedge-shaped fibers may not be able to match the performance of the filtration medium or membrane based system unless customized.