Using stainless steel wire mesh filter to improve PET bottle recycling rate

From our favorite soft drinks to household cleaning products, most of these items are packaged in PET bottles. But have you ever been conflicted about what to do after drinking the bottle? If your answer is recycling, that would be great! You are completely correct.

Recycling: Sustainable Solutions

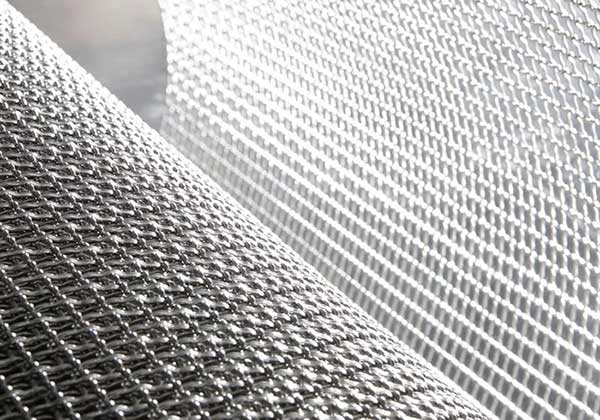

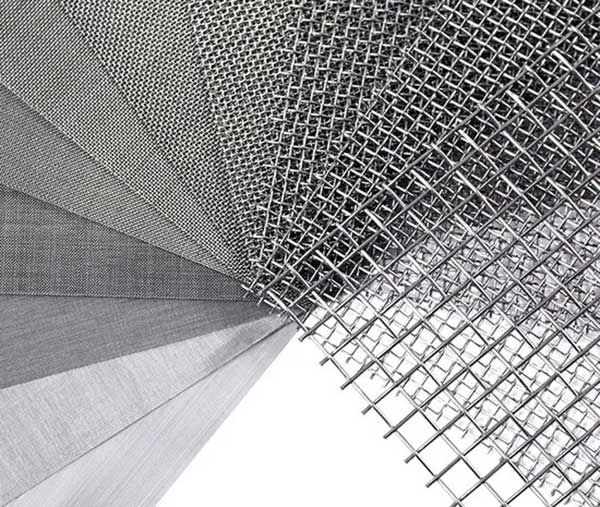

Recycling PET bottles has many advantages, such as energy conservation and emission reduction, as well as significantly reducing landfill waste. The recycling process mainly includes collecting, cleaning, and processing PET bottles, turning them into fibers, and then using them to manufacture new products. The core of this process is how to filter impurities and pollutants, and stainless steel wire mesh filters are the best in this field.

Reasons for choosing stainless steel wire mesh filters

If you are in the PET bottle recycling industry, we have listed the reasons why you should choose stainless steel mesh filters to meet your filtration needs.

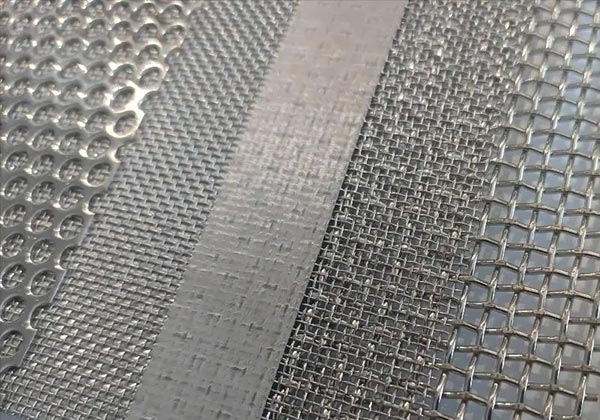

1. Efficient filtration: Stainless steel mesh filters are the preferred choice in primary filtration processes because they can effectively remove unwanted particles from the mixture.

2. Durability and lifespan: The excellent durability and inherent corrosion resistance of stainless steel are the main reasons for its extremely long service life.

3. Cost effectiveness: Compared to other recycling methods that require the separation of impurities from PET materials, it is worth noting that stainless steel mesh filters are a filter that can provide you with an affordable solution.

4. Easy to maintain: Stainless steel wire mesh is easy to install, clean, and maintain, thereby reducing downtime of recycling facilities.

Melting and Extrusion in PET Bottle Recycling

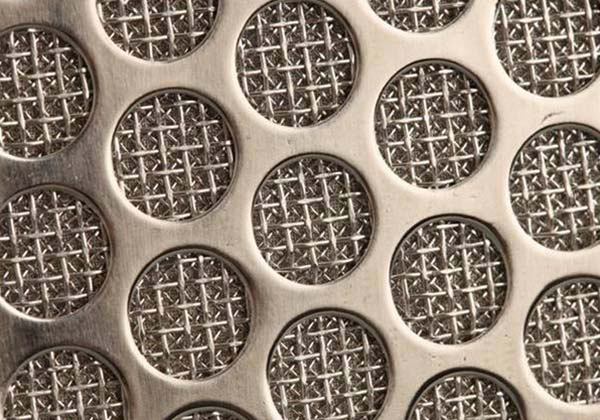

Melting and extrusion are two important stages in PET bottle recycling, involving the conversion of collected bottles into recycled PET material. During this process, the main step after melting the PET bottle is to filter out impurities in order to obtain pure and uniform melted PET material. Stainless steel wire mesh plays an important role here, as it can seamlessly isolate pure PET material from impurities.

These filters can effectively separate pure PET materials from their pollutants, resulting in the highest quality PET products. This process not only ensures excellent product quality, but also promotes the sustainability of the entire process. The melting and extrusion processes are highly dependent on the effective operation of stainless steel wire mesh filters.

Regenerated fiber of stainless steel wire mesh filter

The regenerated fibers extracted from PET bottles can be used to manufacture various other products, such as clothing, shoes, sports equipment, etc. These fibers were obtained by recycling PET bottles with the help of stainless steel mesh filters. Let’s understand how stainless steel mesh filters function in this process.

The recycling process begins with the collection of PET materials, which typically come from discarded PET bottles and are carefully sorted and cleaned using filters to eliminate contaminants. Next, the cleaned PET bottle will be crushed into smaller pieces to prepare for subsequent processing. After crushing, the PET material is then subjected to heating treatment and transformed into molten PET, commonly known as “melt fibers”.

An important step in the recycling process is the use of stainless steel wire mesh filters. PET bottles produce impurities during the melting process, which need to be effectively removed. At this point, stainless steel wire mesh filters known for their durability and corrosion resistance come in handy. After filtration, the purified PET melt fibers are cooled and solidified to form a fibrous structure. The cured fibers are then cut into the desired length and further spun to form the shape of textile fibers.

These high-quality recycled fibers have a wide range of applications, including textiles, household goods, automotive interiors, non-woven products, etc., and have been widely used in multiple industries worldwide. It is worth mentioning that stainless steel wire mesh filters are used in the recycling process to ensure the purity and sustainability of raw materials.

Why is Excelfilter the best manufacturer for filters?

1. High quality materials: We manufacture high-quality stainless steel wire mesh to ensure the service life of your products and provide you with the best performance.

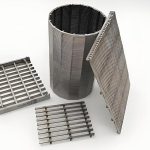

2. Customization: Excelfilter filters meet the needs of various industries. We offer various filter options that can be customized according to different recycling processes.

3. Professional knowledge: Excelfilter has over 10 years of rich experience and technical knowledge, and can provide you with efficient filtration solutions that meet the unique requirements of the recycling industry.

Recycling PET bottles is a wise and environmentally friendly method that can solve the problems caused by their widespread use. Stainless steel wire mesh filters are crucial as they can efficiently filter and help optimize the recycling process. Using these filters in the melting and forming stages of recycling can also make the entire process more efficient and clean, thus benefiting the environment.