The key role of metal wire mesh in chemical manufacturing

For many years, the chemical manufacturing industry has been the cornerstone of economic growth, leaving an indelible mark in various industries and making significant contributions to the country’s GDP. This accomplished industry covers a wide range of chemical processes, from basic chemical manufacturing to the production of specialized compounds, which have been used in countless applications. Although it may not always make headlines, an essential element that plays a crucial role in the chemical manufacturing industry is wire mesh.

Chemicals are components of various products, including pharmaceuticals, plastics, agricultural chemicals, etc. Therefore, this industry has become the cornerstone of economic development, driving innovation, job creation, and export opportunities.

Understand the unique needs of the chemical industry

Chemical manufacturing is carried out under harsh conditions, typically involving the handling of corrosive substances, extreme temperatures, and extremely high pressures. The main aspect is to ensure the safety and efficiency of the manufacturing process in this challenging environment. At this point, the wire mesh became an unknown hero. The cooperation between chemical manufacturers and professional wire mesh manufacturers is crucial for the sustained growth of the chemical industry.

Metal Wire Mesh: The Power Behind the Scenes

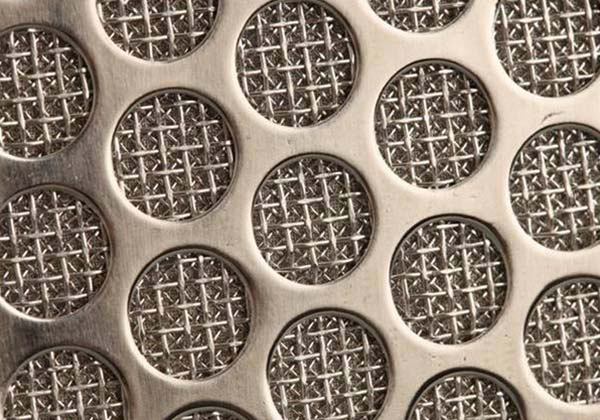

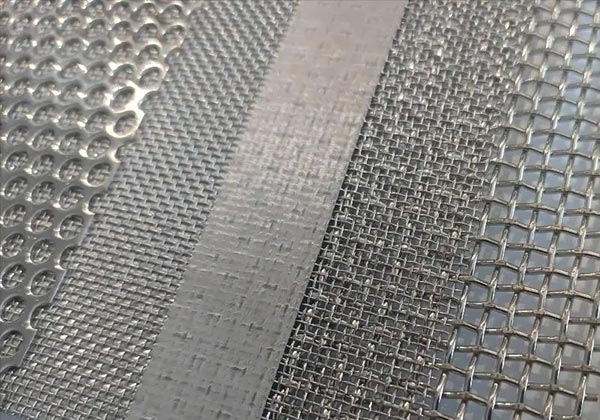

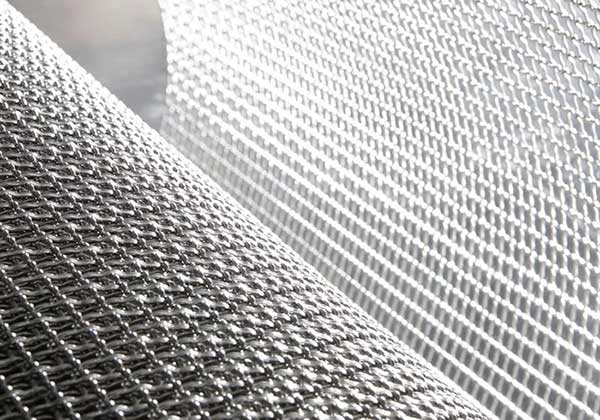

Metal wire mesh is a widely used material composed of interwoven metal wires, forming a grid like structure with precise openings. It is an indispensable component in various stages of chemical manufacturing, especially in filtration and separation processes. The following are absolutely important reasons for metal wire mesh:

1. Filtration and separation

In chemical manufacturing, separating solids from liquids or gases is the main step. Metal wire mesh screens and filters have fine or coarse mesh, which can skillfully capture particles of different sizes and ensure the purity of the final product. These screens are made of various materials, but the most commonly used is stainless steel, which is known for its corrosion resistance and long service life.

2. Unified traffic control

Metal wire mesh plays a crucial role in pipeline filters and online filters, maintaining stable flow of liquids or gases. By preventing harmful particles from entering, metal wire mesh can protect the integrity of equipment and ensure the quality of the final product.

3. Catalyst support

Some chemical processes rely on catalysts to accelerate reactions. Metal wire mesh provides excellent support structure for catalyst beds, ensuring the uniform distribution and efficient utilization of these key materials in the chemical industry. The catalyst support system benefits from metal mesh manufacturers such as Excelfilter to achieve uniform efficiency.

4. Heat transfer

Most chemical processes require heat transfer equipment such as heat exchangers. Metal wire mesh can provide a stable heat exchange surface, improve heat transfer efficiency, and thus reduce energy consumption.

5. Durable and low maintenance cost

Metal wire mesh is known for its durability and ease of maintenance. It can withstand the harshest chemical environments, is not only durable, but also an economical choice. As long as you purchase wire mesh from well-known wire mesh manufacturers such as Excelfilter, you can easily achieve this.

6. Continuous process reliability

Chemical manufacturing involves processes that operate continuously for long periods of time. Interruptions or shutdowns can be costly and may result in interruptions. Metal wire mesh has the characteristics of durability and low maintenance, which can ensure the reliability of the entire process. It is wear-resistant and will not degrade after long-term operation.

7. Quality assurance and regulatory compliance

Compliance with environmental and safety regulations is crucial for every industry. Metal wire mesh helps chemical manufacturers comply with regulatory standards by effectively controlling emissions and reducing safety risks, thereby winning the trust of consumers and regulatory agencies.

Wire mesh manufacturers: meet industry demands

With the increasing dependence of the chemical industry on metal wire mesh, the role of metal wire mesh manufacturers has become increasingly important. Metal wire mesh manufacturers like Excelfilter, with their rich experience and strong commitment to quality, provide customized metal wire mesh solutions for the chemical industry that fully meet the specific applications of their customers.

The metal mesh product line of Excelfilter is designed to meet the strict requirements of the chemical manufacturing industry. In the constantly evolving field of chemical engineering, metal wire mesh produced by manufacturers such as Excelfilter remains the cornerstone of innovation. Their carefully designed wire mesh screens, filters, and support structures help ensure efficient operation of chemical processes while maintaining the highest safety and quality standards.