The importance of metal wire mesh in filtration

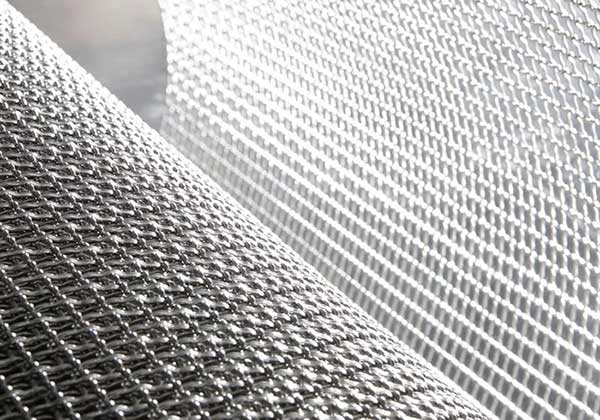

Filtering is an important process in both industrial and household environments. Filtering separates solid or unwanted impurities from liquids or gases through porous media, ensuring the quality and safety of various products and systems. Metal wire mesh is one of the best in this process. This inconspicuous but crucial component is the key to the filtering process, as it has made significant contributions to the success of various industries.

Precision and customization

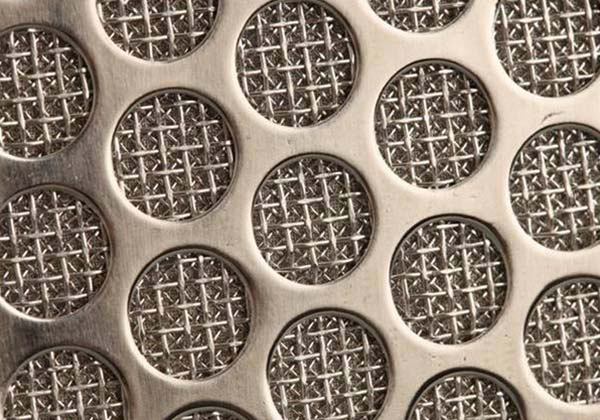

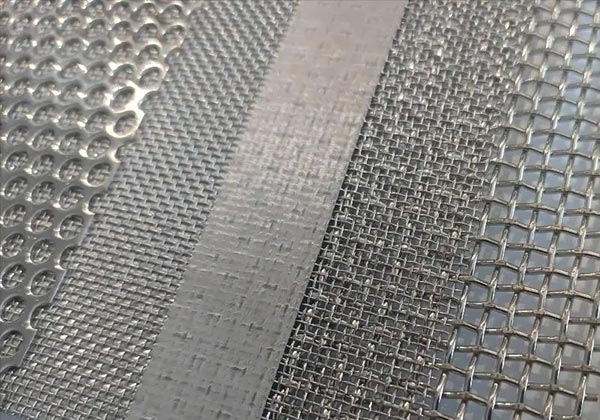

Metal wire mesh emphasizes precision and customization. These screens can meet the unique needs of industrial and household filtration. They come in various grid sizes and configurations, allowing users to fine tune or customize filtering systems according to their specific requirements. Whether removing fine particles from liquids or gases, metal mesh screens can be adjusted to achieve the desired filtration level while ensuring optimal performance in different applications.

Durability and service life

One of the significant features of metal wire mesh screens for filtration is their excellent durability and service life. These two characteristics are sufficient to make it a reliable choice in the field of filtering. They can withstand harsh conditions, handle high flow rates, and withstand abrasive materials without showing signs of wear. This durability not only reduces maintenance costs, but also enables the filtration system to operate continuously.

Improve filtration efficiency

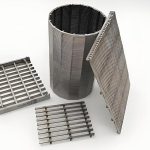

Efficiency is the key to filtration, and metal mesh screens are now the undisputed champions. The design of the metal wire mesh screen has a larger open area, which can increase the flow rate and cleverly capture particles and pollutants. The unique combination of high flow and top-notch metal mesh screens in filtration makes them the preferred choice for applications where flow rate and particle removal are non-negotiable.

Chemical compatibility

Metal wire mesh screens are made of various materials, including stainless steel and alloys, and have excellent chemical corrosion resistance. This chemical compatibility is crucial for industries that frequently involve corrosive chemicals. Siriram Filters guarantees to customers that their metal mesh screens will not react with the filtered substances during the filtration process, ensuring safety and efficiency.

Easy to maintain and clean

Easy maintenance and cleaning are crucial in both industrial and household environments. Metal wire mesh screens are easy to use, which means you can easily disassemble, clean, and reinstall them. Their design and material characteristics make the entire cleaning process easy and worry free. Metal mesh screens can reduce maintenance costs and provide uninterrupted filtration, whether in large industrial facilities or in your home.

Key manufacturing industry relying on metal wire mesh

- Pharmaceutical: In the pharmaceutical industry, maintaining excellent purity levels is non-negotiable. Metal wire mesh filtration helps in the production of drugs as it can meticulously remove impurities, ensuring that the final product meets strict quality standards.

- Food processing: Metal wire mesh screening is an indispensable part of the food processing industry, which can be used to screen flour, filter liquids, and separate solids from liquids. They are crucial for maintaining product quality and safety.

- Textile industry: The dyeing and printing processes in the textile industry rely on metal wire mesh. They can ensure uniform color distribution and effectively eliminate impurities in the dye.

- Petrochemical industry: The petrochemical industry relies on metal wire mesh screens to separate gases and liquids at different levels. Therefore, metal wire mesh screening is an indispensable part of the refining process.

- Water treatment: Transporting clean drinking water is of utmost importance, and metal wire mesh screens play an important role in water treatment plants as they can eliminate impurities from household water supply.

Household use of metal wire mesh in filtration

1. Screens: These screens can protect your home from harmful insects and allow fresh air to circulate freely.

2. Drainage ditch protection device: The metal mesh in the filter can prevent debris and leaves from blocking the drainage ditch, thereby reducing the need for frequent maintenance.

3. Horticulture: Metal wire mesh screens are very useful when creating garden pergolas.

Metal wire mesh screen is an important component of industrial and household filtration applications. Their precision, durability, sustainability, versatility, and ease of maintenance make them the backbone of various industries and household filtration systems. By selecting metal wire mesh screens during the filtration process, both the industry and homeowners can improve the efficiency and effectiveness of the filtration process, ultimately improving product quality, reducing operating costs, and achieving more sustainable operations. In a world that relies on first-class filtration, metal wire mesh screens have proven their strength by meeting the diverse needs of industrial and household applications. Contact us to learn how we can assist you.