The importance of candle filter in polymer manufacturing

For all participants in the polymer manufacturing field, if you are looking for cutting-edge filtration solutions, candle filters are likely to be your top choice for consideration. In this blog, we will delve into the key role that polymer candle filters play in the field of polymer manufacturing. But before that, let’s first understand what a candle filter is.

What is a candle filter?

Candle filters are specially designed filter elements used to remove impurities and contaminants from polymer melts during the manufacturing process, ensuring the production of high-quality polymer products. These filters are designed to ensure the highest quality standards for polymer manufacturing.

What sets them apart?

The difference between candle filters and traditional filters lies in their excellent filtration efficiency, longer service life, and ability to maintain consistent high-quality standards, making them an ideal choice to meet the strict requirements of the polymer manufacturing industry.

Construction and operation principles

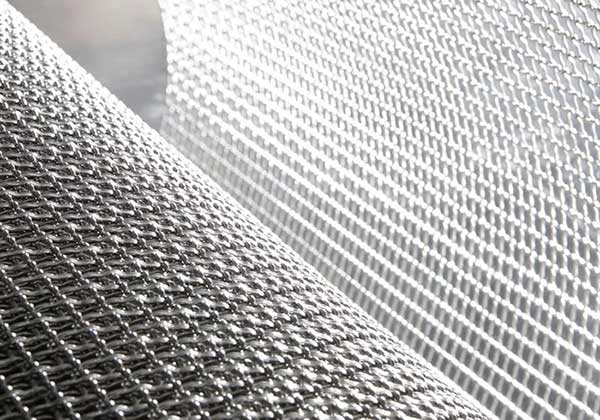

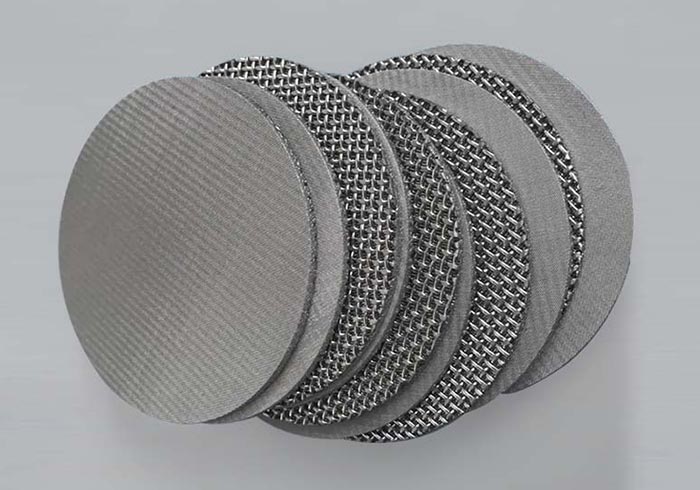

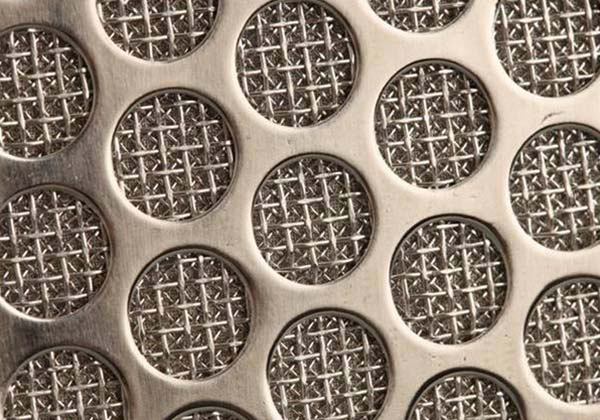

The construction of candle filters is a reflection of engineering accuracy. Its core is the polymer filter element, which is an important component for efficiently capturing pollutants and impurities. These filters are similar to candles and are made of high-quality materials that can withstand the extreme temperatures and pressures encountered during the polymer manufacturing process. Polymer filter cartridges are made of sintered metal or ceramic materials and are the foundation of all candle filters. This core contains a complex channel network that forms intricate filtering paths.

The term polymer candle filter represents the precision and excellence in ensuring the purity of polymer products. Candle filters operate when polymer melt flows through. Along this complex path, pollutants are captured, leaving only pure polymers. This process ensures that the final polymer product meets the strictest quality standards.

Application of candle filter

As a filter manufacturer, Excelfilter has always been an important contributor to various industries that rely on polymer manufacturing. These multifunctional filters are suitable for various environments. They play an important role in the production of numerous polymer based products. Filters play a crucial role in ensuring the quality and reliability of polymer based products.

The advantages of candle filters

- Excellent filtration efficiency: Candle filters are adept at removing the smallest pollutants and ensuring that you obtain the purest final polymer product.

- Stable quality: Candle filters help maintain a consistent level of polymer quality, which is crucial for product performance and reliability.

- Economically efficient: Candle filters can help manufacturers save costs in the long run by minimizing waste.

The role and significance of polymer filters

Polymer candle filters play a crucial role in the polymer manufacturing process. They are frontline guardians to prevent impurities from entering. In industries where accuracy and consistency are crucial, these filters are a guarantee of product quality. The design and quality of polymer filter cartridges make candle filters a key component in polymer manufacturing. As a candle filter manufacturer, Excelfilter has always been a pioneer in this field, providing services to the industry.

The importance of candle filters extends to the reputation of polymer manufacturers. By continuously producing high-quality polymer materials, not only can customer needs be met, but the company’s position in the industry can also be enhanced. As a well-known filter manufacturer, Excelfilter understands the profound impact of these filters on the success of polymer manufacturing. Thanks to the innovative engineering of polymer filters, manufacturers can now consistently achieve the highest standards of polymer purity and quality.