Stainless steel sintered wire mesh for filtration equipment

Stainless steel sintered wire mesh is a special type of filter media used in filtration equipment across a wide range of industries. It is known for its superior filtration efficiency, mechanical strength, and durability. Here are some key points about stainless steel sintered wire mesh for filtration equipment:

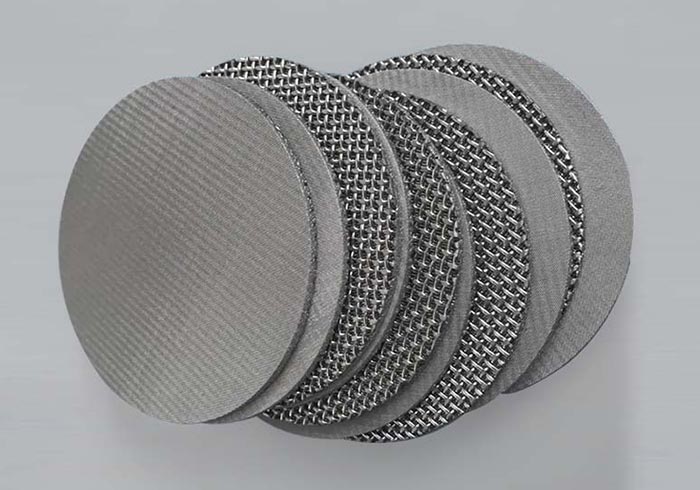

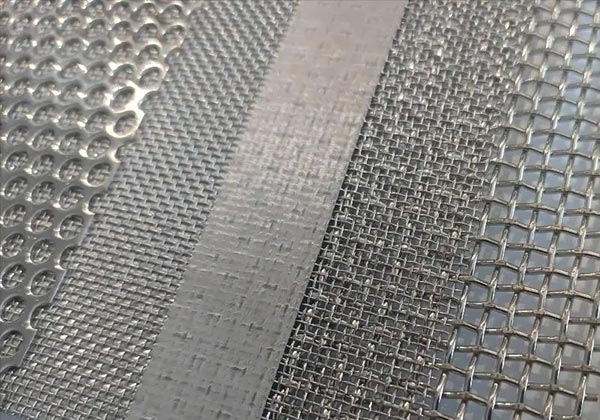

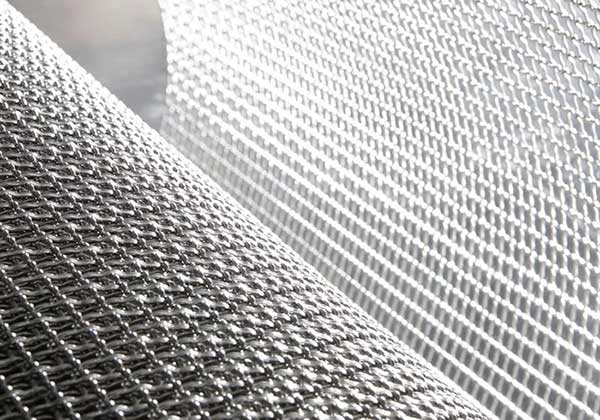

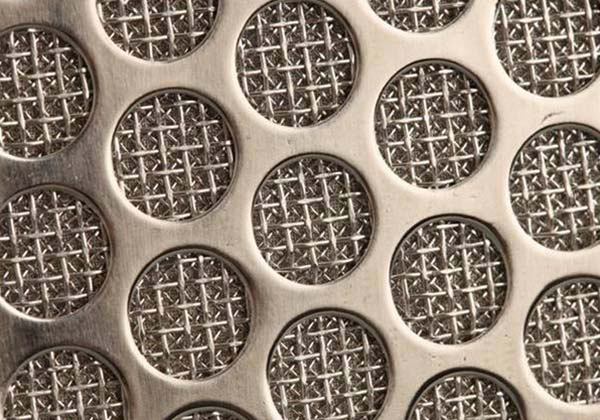

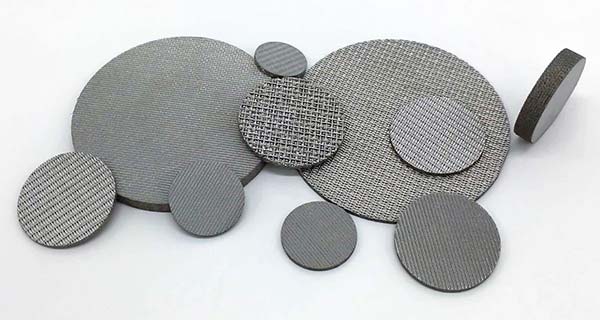

1. Material composition: Stainless steel sintered wire mesh is usually made of multiple layers of stainless steel woven wire mesh. The layers are stacked and then sintered (bonded) together at high temperatures to form a porous, rigid structure.

2. Filtration efficiency: Sintered wire mesh offers high filtration efficiency due to its fine and uniform pore structure. It can effectively capture particles of varying sizes, making it suitable for a wide range of applications from coarse to fine filtration.

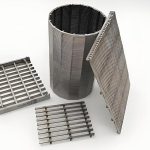

3. Mechanical strength: The sintering process gives the mesh excellent mechanical strength and stability. It can withstand high pressure differentials and does not easily collapse or deform under pressure, which makes it suitable for demanding industrial filtration tasks.

4. Chemical compatibility: Stainless steel is corrosion-resistant and chemically compatible with a wide range of fluids, making it suitable for use in aggressive environments.

5. Temperature resistance: Stainless steel sintered wire mesh can withstand high temperatures, which makes it suitable for applications involving hot gases or liquids.

While stainless steel sintered wire mesh may have a higher initial cost compared to some other filter media, its long-term durability and low maintenance requirements generally make it a cost-effective choice in the long run. Its combination of superior filtration efficiency, mechanical strength, corrosion resistance, and extreme temperatures makes it a top choice for many industrial and commercial filtration needs.