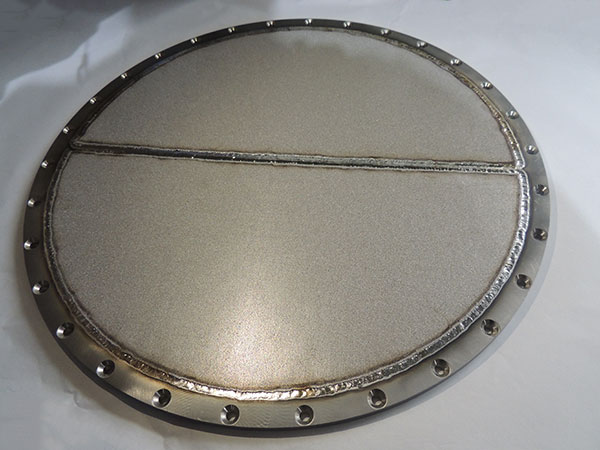

Wedge Wire Screen

Wedge wire screen consists of wedge wire and support profiles with a “V” shaped surface and a “groove” shaped interior, hence the name “V” shaped wire mesh or groove wire mesh. The wedge wire has a triangular cross-section, a large filtering area and a high porosity, which can effectively prevent clogging and damage. Wedge wire screen is characterized by high strength, high precision, good corrosion resistance, good high temperature resistance and not easy to clog. Therefore, it is widely used in the field of filtration and separation in water treatment, petrochemical, food processing and other industries.

Working Principle of Wedge Wire Screen

Wedge Wire Flat Screen Filtering

When the fluid or gas passes through the continuous slit formed by the V-shaped wire mesh, the larger particles will be filtered out and separated from the desired material. This is because larger particles cannot pass through the narrow slits and become trapped on the screen surface.

Wedge Wire Screen Cylinder Filtering

As the effluent passes through the wedge wire screen tube, the solids are trapped on the mesh surface. The water that passes through the mesh flows out through the flat screen outlet below, while the intercepted solids collect and roll along the mesh surface to the scum drop plate, achieving solid-liquid separation.

Specification of Wedge Wire Screen

Material: stainless steel 304, 316, 316L, Hastelloy, Monel alloy and so on.

Wedge wire shape: triangular, conical and prismatic.

Common specification of wedge wire: 1.00 mm × 2.00 mm.

Support profile shapes: rectangular, tapered and teardrop shaped.

Common size of support profile: 2.00 mm × 3.00 mm.

How to select the appropriate wedge wire structure and flow direction?

The selection of the appropriate structure and flow direction for a wedge wire screen depends on the specific requirements of your application and the type of filtration or separation you need to achieve. Determining the direction of water flow in a wedge wire screen depends on the position of the wedge wire (surface profile) in relation to the support profile. There are two flow directions in wedge wire screens, i.e. from outside to inside or from inside to outside.

- Radial external type

- Radial built-in type

- Axial external type

- Axial built-in type

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.