Wedge Wire Filter Elements

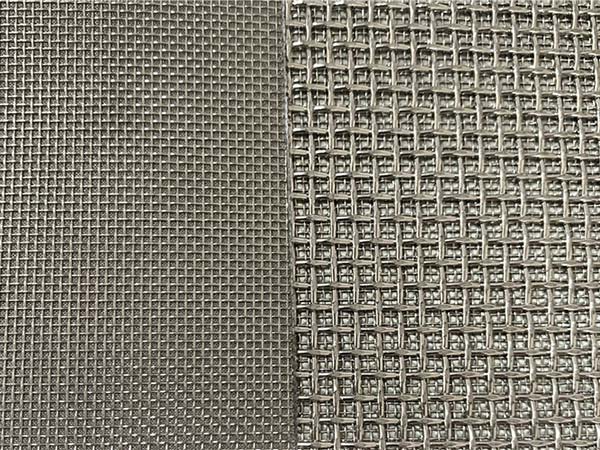

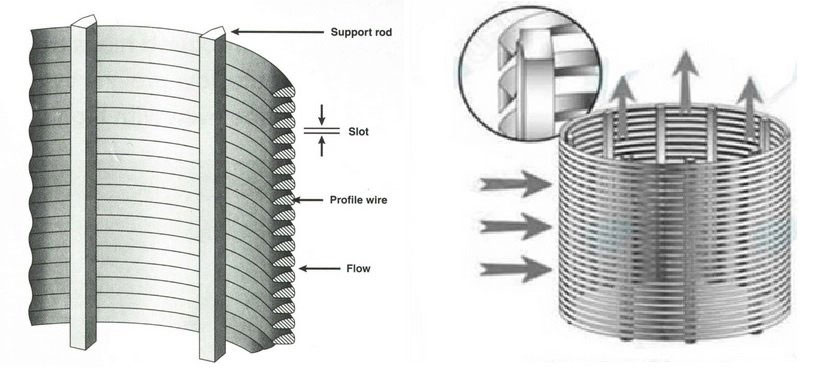

Wedge wire is a filter medium made of profiled wire. The profile/surface wire is precisely aligned and then welded to the support rods mainly by automatic resistance welding. Both the profile and the support wire can have a certain wedge shape or other cross-sectional shapes, such as teardrop, round or trapezoidal.

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are standard materials for wedge wire filter elements.

Other exotic materials are also available on request, such as duplex stainless steel 2205, 2507, SS 904L, Hastelloy C276, Hastelloy C22, etc.

Wedge wire mainly appears in two forms: slotted tube (cylindrical filter element) and flat screen (Johnson screen, screen mesh). Filter grades range from 25 to 3000 microns.

Advantages of wedge wire filters

- Sturdy construction, high strength

- Excellent media retention

- Superior backwashing capability

- Less likelihood of clogging

- Long service life

- Low maintenance cost

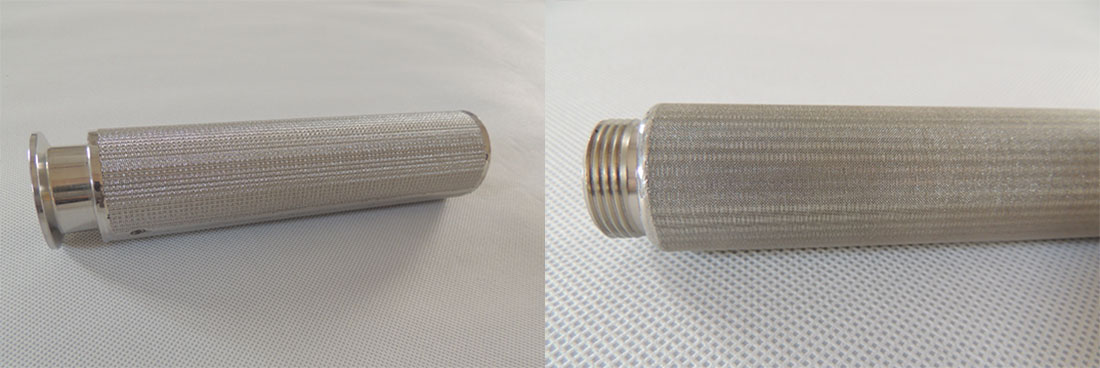

Wedge wire filter cartridges/candles

Wedge wire filter elements mainly include filter cartridges (candles) and tube screens. Wedge wire filter cartridges can be used for direct filtration of fluids, and can also be used as filter media support for media filtration such as diatomaceous earth and gravel.

wedge metal wire filter cartridge with external threaded end fittings

wedge shaped metal wire filter cartridge

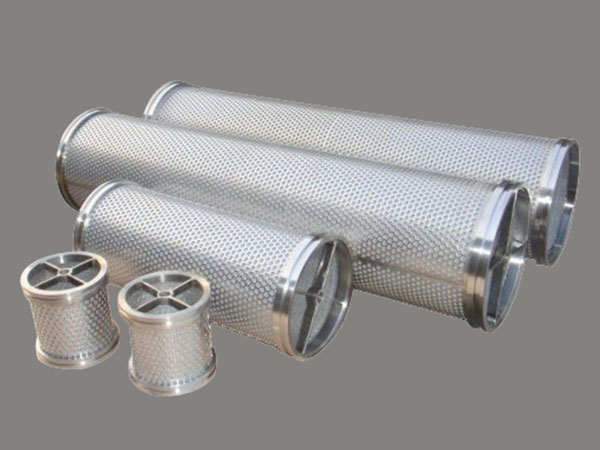

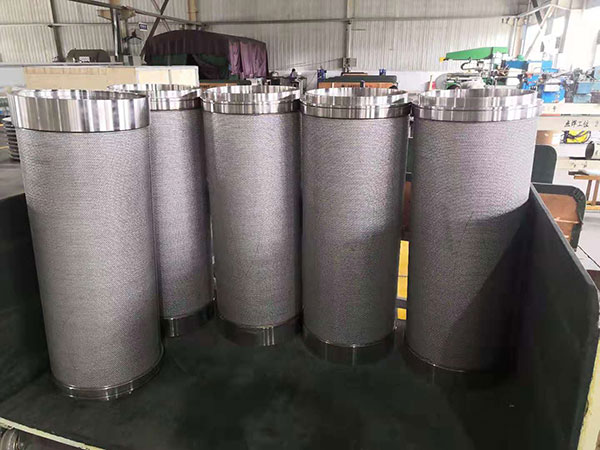

Wedge wire filter tube screens

Wedge wire filter tube screens are often used in automatic self-cleaning filters, especially for handling large amounts of fluids and impurities of hundreds of microns and above.

wedge wire filter tube filter screen for automatic self-cleaning filters

wedge shaped metal wire filter tube filter screen for water filters

Inverted section inside and outside slotted tube wedge wire filter

Inverted section slotted tubes have flat surfaces on the section line welded to the support rod. Therefore, the smooth surface of the tube is inside the tube. The flow direction becomes from inside to outside. This countercurrent wedge wire filter is often used in self-cleaning filters.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.