Standard 5‑Layer Sintered Wire Mesh

The standard 5-layer sintered wire mesh is the most commonly used sintered wire mesh for filtration and separation, which we call A-type.

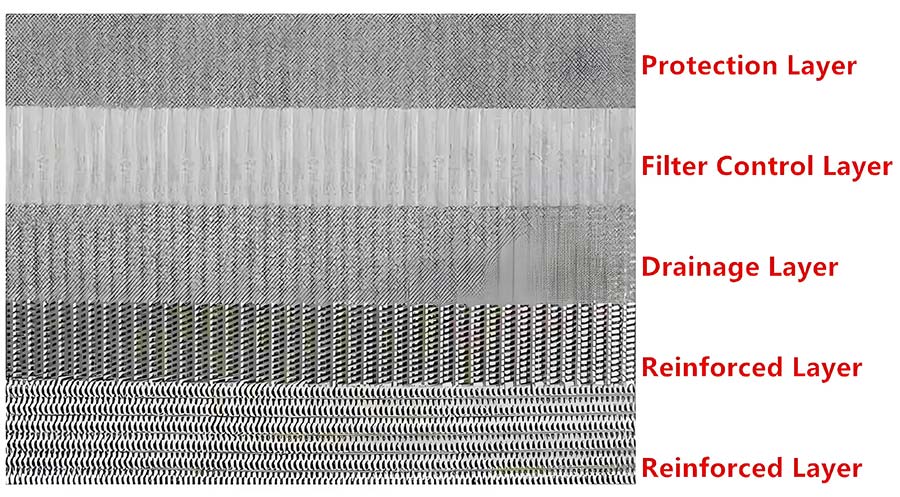

Layer Structure of Five-layer Sintered Wire Mesh Laminate

The surface layer of A-type is 100 mesh plain square weave wire cloth, which is the protective layer of the second filter control layer. The control layer determines the filtration level, which can be square weave, Dutch weave, twill weave or other types of wire cloth. The third layer is usually the same as the first layer, but usually acts as a dispersion and transition layer. The fourth and fifth layers are both 12×64 Dutch weave wire mesh, but with a 90-degree change. These two reinforcement layers provide support and strength for the sintered wire mesh.

standard 5 layer sintered wire mesh layer structure

Common filter ratings for A-type sintered wire mesh include 1 2 5 10 20 microns. Other micron ratings are also available upon request.

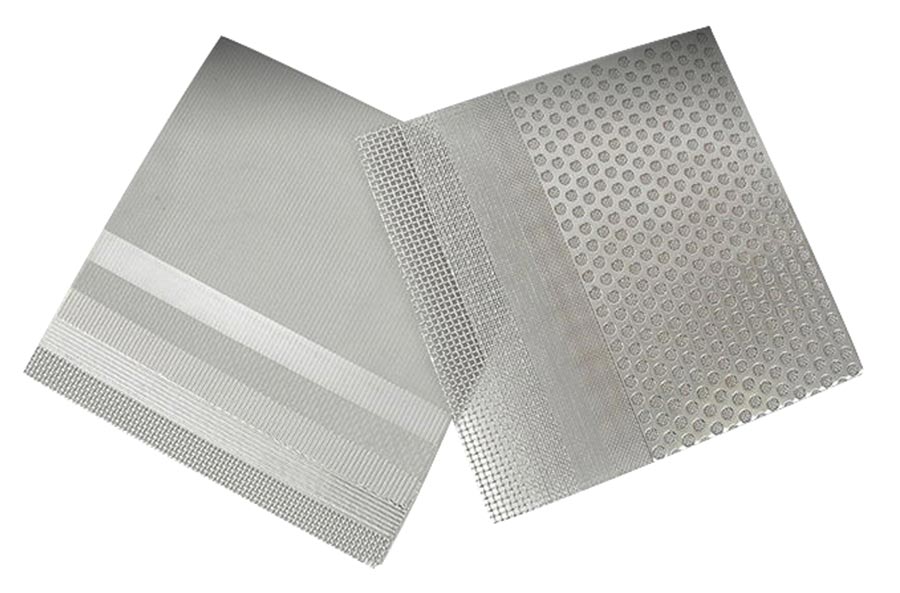

For some situations where higher pressure resistance is required, we will add an additional sixth layer of 12 mesh wire mesh to provide greater thickness and higher strength.

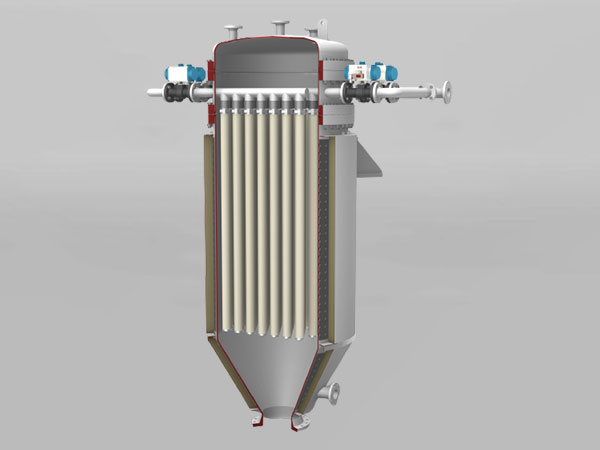

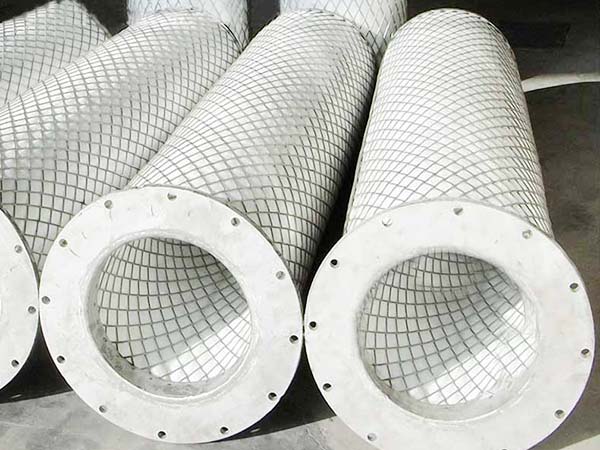

Filter element types made of 5-layer standard sintered wire mesh

Filter elements of sintered wire mesh type can be formed into filter cartridges, filter baskets/filters, filter discs, filter cones, filter tubes for almost all applications with micron filtration requirements.

5 layer sintered wire mesh

6 layer sintered wire mesh with additional coarse mesh

Specification of 5 layer sintered wire mesh

| Model | Nominal Rating μm | Structure | Thickness | Air Permeability l/min/cm2 |

Bubble Point Pressure mmH20 |

|---|---|---|---|---|---|

| A5-1 | 1 | 100+400×2800+100+12×64+64×12 | 1.7 | 1.81 | 360-600 |

| A5-2 | 2 | 100+325×2300+100+12×64+64×12 | 1.7 | 2.35 | 300-590 |

| A5-5 | 5 | 100+200×1400+100+12×64+64×12 | 1.7 | 2.42 | 260-550 |

| A5-10 | 10 | 100+165×1400+100+12×64+64×12 | 1.7 | 3.00 | 200-500 |

| A5-15 | 15 | 100+165×1200+100+12×64+64×12 | 1.7 | 3.41 | 200-480 |

| A5-20 | 20 | 100+165×800+100+12×64+64×12 | 1.7 | 4.50 | 170-450 |

| A5-25 | 25 | 100+165×600+100+12×64+64×12 | 1.7 | 6.12 | 150-410 |

| A5-30 | 30 | 100+400+100+12×64+64×12 | 1.7 | 6.70 | 120-390 |

| A5-40 | 40 | 100+325+100+12×64+64×12 | 1.7 | 6.86 | 100-350 |

| A5-50 | 50 | 100+250+100+12×64+64×12 | 1.7 | 8.41 | 90-300 |

| A5-75 | 75 | 100+200+100+12×64+64×12 | 1.7 | 8.70 | 80-250 |

| A5-100 | 100 | 100+150+100+12×64+64×12 | 1.7 | 9.10 | 70-190 |

| Thickness: 1.7(mm); Porosity : ~37%;Weight kg/m²: 5-layers sintered wire mesh (8.4) 6-layers sintered wire mesh (14.4). 6-layers construction adds additional 12 mesh to ordinary 5-layers mesh for better pressure resistance, thus thickness reaches 3.5mm. |

|||||

Material options for standard 5-layer sintered wire mesh

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are standard materials for type A sintered wire mesh.

Other exotic materials are also available on request, such as 310S, 904L, Hastelloy C276, Hastelloy C22, Monel 400, Inconel 625, etc.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.