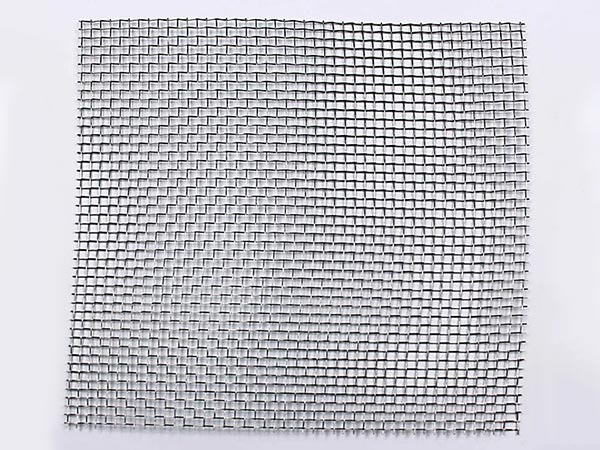

Stainless Steel Mesh Filter

Excelfilter offers stainless steel mesh filter in 304 or 316L stainless steel. Stainless steel wire mesh filters are available in a variety of configurations, including Stainless Steel Filter Cartridges. Because the material properties of stainless steel mesh are more flexible, we can customize it in any shape according to the customer’s specific application needs. For high-purity industrial filtration applications for special water treatment, Excelfilter offers a wide range of apertures from 1-5 micron stainless steel mesh filters or 100 mesh filter screens.

Excelfilter‘s wire mesh filter screens are suitable for various applications that require different aperture sizes. These stainless steel mesh filter cartridges can be combined with perforated metal or porous metal woven mesh for versatile configurations. Even in corrosive operating environments, the wire mesh filter screen can maintain its integrity and interception efficiency.

We offer single-layer or multi-layer combinations of stainless steel filter screens, aiming to meet various customer needs for filtration applications of different sizes. Standard weave options include plain, twill, and Dutch weave patterns.

Different customers have different requirements for manufacturing processes. These woven wire mesh filters can be manufactured by stamping, sintering, resistance welding, CNC, TIG welding, and micro-welding processes to meet customer needs. Whether it’s a fine chemical process or a heavy industrial fluid application, our stainless steel mesh filters prevent chips, burrs, and wear particles from damaging your fluid system with long-lasting durability and particulate interception efficiency.

In the environment of various pumps, in order to prevent the pump from blocking or damaging the impeller, we specially designed the mesh filter screen for pump and the mesh filter screen for pipe. They can effectively intercept and remove impurities from liquid systems.

Sintered Mesh

The sintered mesh made of woven wire mesh with different meshes by vacuum high-temperature firing has high mechanical strength and uniform pore size, and the micron scale ranges from 1 to 100 microns. Sintered wire mesh filter media provide absolute retention ratings across a wide range of degrees of filtration for liquids and gases.

Woven Steel Wire Mesh

Woven steel wire mesh is a low-cost and highly efficient filtration medium, with a micrometer-level range between 1 and 2000 micrometers. Because parameters such as wire diameter, mesh count, and weaving pattern of woven wire mesh are fully customizable, it comes in PW (plain) and TW (twill) square weaves, as well as PDW (plain Dutch) and TDW (twilled Dutch) Dutch weaves.

Photo Etching Metal Filter

The filter medium of the photo etching metal filter has a smooth surface and a larger open area. The smooth surface reduces the flow resistance and pressure difference of the liquid, thus allowing the liquid to be filtered at a lower pressure difference. Easier cleaning and maintenance for the photo etching metal filter to intercept burrs and wear particles in the system.

Laminated Perforated Sheet Metal

Laminated perforated sheet metal filter media are sintered together with perforated sheet metal and multiple layers of woven steel wire mesh, which forms a very strong and easy-to-handle porous sheet. It has high-pressure resistance and high mechanical strength. Suitable for environments requiring fine filtration and high-pressure operation.

Stainless Steel Mesh Filter Cartridge

Stainless Steel Filter Screen (Sintered Mesh)

Configuration

In order to meet different working conditions and specific installation requirements, Saifilter’s stainless steel mesh filter provides users with customized designs. The standard configuration components are as follows.

- Thread connection(BSPP、NPT)

- Flange connection.

- Rod connection.

- Double Open End(DOE)

- Single Open End(SOE)

Nominal Dimensions

- Diameter: 6mm (2.4″) to 800mm(24″)

- Length: 10mm (0.3″) to 1200mm (36″)

Other diameters and lengths are available on request

Operating Conditions

- Temperature limit with Buna-N gaskets: 121℃ (250°F), other gasket materials to 232°C (450°F). From -269℃( -452°F ) to 420℃ ( 788°F ) alloy limiting.

- Normal flow direction: 2bar (29psi) to 50bar (725psi)

- Reverse flow direction: 1bar(14.5psi) to 42bar (609psi)

Technical Details

- Micron size range:1-2000μm

- Different media options: From 1-layer to 7-layer mesh, configurations, standard options include metal woven mesh, photo Etching Metal, and Laminated perforated sheet metal.

- Materials of construction: carbon steel, SS304, 316L

- Gaskets: PTFE, Buna-N2, Graphite composite

Stainless Steel Mesh Filter Features And Benefits

- Flexible Configuration: We can provide different aperture sizes, dimensions, and end connection methods.

- Rapid production: Can be produced within 7 days for standard end connection and sealing configurations.

- Optimized Flow Rate: Achieve optimal fluid filtration.

- Uniform Aperture: Attain absolute filtering aperture effect.

- High Stability: Maintain stability under various operating conditions.

- Easy Cleaning: Facilitate maintenance and long-term use.

- Ease of Machining: Capable of manufacturing different shapes and sizes as per requirements.

- Versatility: Applicable in the fields of gas-solid separation and liquid-liquid separation media.

- Direct Replacement: Filters come in compatible sizes and can replace well-known brands such as PALL, PORVAIR, GKN, and NORMAN.

- Compatibility: Compatible with various liquid or gas media, suitable for operation in harsh environments (including corrosive conditions, high-temperature synthesis gases, or high differential pressures).

- Product Traceability: Each stainless steel mesh filter is provided with laser-engraved numbering, and entered into a product traceability system for simplified tracking and management.

- Multiple Cleaning Cycles: Depending on the contamination level of the wire mesh filter screen and the type of fluid media, different cleaning processes can be chosen, such as high-temperature steaming, chemical cleaning, and ultrasonic cleaning. The recommended cleaning lifecycle is 2-3 times.

Applications

- Faucet Screens

- Cosmetic

- Chemical

- Water treatment

- Aerospace and oil/gas industries

- Solvents, paints, water

- Filtration, sifting, sizing

- Vents

- Baskets

- Strainers

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.