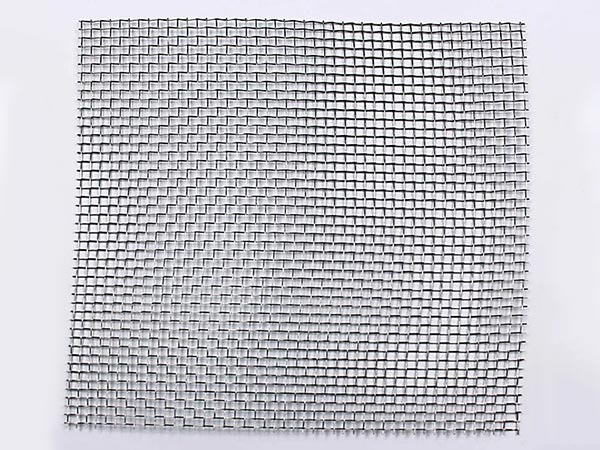

Stainless Steel Filter Mesh

What is stainless steel filter mesh?

As the name implies, this type of filter is a filter mesh constructed out of stainless steel. There are numerous available applications of stainless-steel filters but generally for filtration in locations with relatively hostile environmental conditions. Stainless-steel filters find usage in the following industries, Food & Pharmaceutical, Engineering, Petroleum & Chemical, Environmental Protection, Electronic, Aerospace, Paper Making, Metallurgical, Filtration & Separation, Mining.

To contribute to its flexibility, mesh openings are workable in several forms like mesh water filters, fine mesh filters, or filter screen meshes and layers. These are available in equally varying styles, such as round, oval, or rectangular, with an option for single or multiple layers. In essence, stainless-steel filters are reusable, customizable, and are available in many preferable configurations aside from their long-lasting and high-quality nature. According to the specific requirements of customers, stainless steel filter meshes can undergo welding, sintering, and other processes to customize them to various mesh sizes, lengths, and the like.

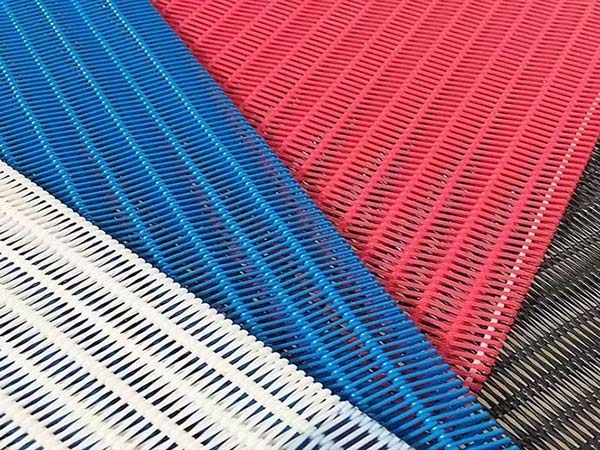

The Woven Styles of Stainless Steel Filter Mesh

All kinds of precise stainless steel woven meshes can be produced by Excelfilter stainless steel filter mesh manufacturer, from conventional square meshes to Hollander twill meshes. It also can provide the most accurate absolute level. The simple square meshes are converted to Hollander twill meshes through all kinds of patterns (Hollander reversed plain weave meshes, wide mesh twill, single plain weave).

Stainless steel woven meshes are nearly appropriate for any application because of their fantastic multifunctionality. It is weaved on a weaving machine. This process is similar to the procedures of knitting clothing shell fabric. The meshes can be used for the components of the various curly patterns in interlocking. This interlocking method requires accurate placement of the wire rods above and below each other before the wire rods are crimped in place to generate solid and reliable Stainless steel woven mesh products. It is an ideal choice for manufacturing metal mesh filtration elements. Most can provide you with all-sided stainless steel filter mesh choices in the application of surface filtration.

- Plain / Double: The woven types of standard woven metal mesh can produce square trepanning, which is a common interlinked way. There are the same meridians and wefts, and the meridians alternate at right angles above or below the filling line.

- The twill square: The woven types are similar to conventional Hollander meshes except for the twill woven styles. Every metal wire goes through two metal wires, and the metal wire with a smaller diameter is still used after the traverse. It is always used in the application of subtle filtration, and the twill square woven meshes show unique patterns of parallel diagons.

- Twill Dutchis: famous for its remarkable strength, which is realized by packaging abundant wire rods. The woven metal meshes can also filtrate particles as small as 5 microns.

- Reversed plain Dutch: The woven style is the same as conventional Hollander meshes, except that the meridians and wefts are opposite. The bigger wefts are more closely weaved together than that are seen in standard Hollander meshes.

- Plain Dutch: It is a very close-woven way because the thinner and smaller diameter wefts are used. Compared with the understandable weave styles, there is no straight and transparent, open mouth in Hollander weave. On the contrary, woven forms generate a spiral path, through which the very subtle filtration and particle reservation are realized. The Hollander weave can be appointed by “gridding counts” or “absolute filtration grading.” The stainless steel woven wire meshes are mostly used in the application of industrial filtration fabrics.

Characteristics and Advantages

- Small loss of system pressure

- Good gas permeability

- High tensile strength

- From single-deck package design to complex multilayer construction of the folded structure, the available area can be optimized.

- Any filtration medium types of most large aperture sizes are provided.

- It can be used in 316L stainless steel and other alloy standards, such as chromium-nickel-iron alloys, Hartz, and Monel.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.