Sintered Metal Mesh Filter Disc Plates

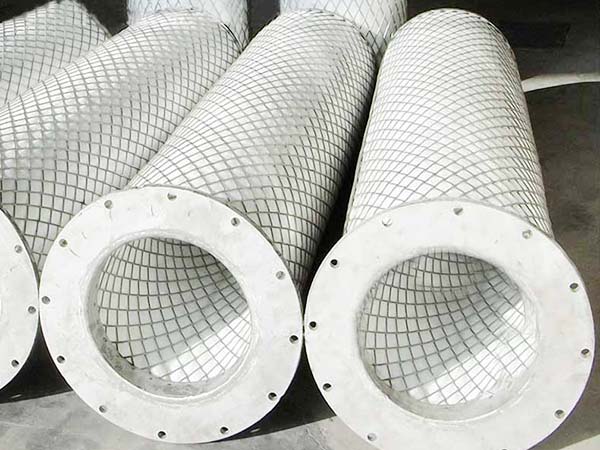

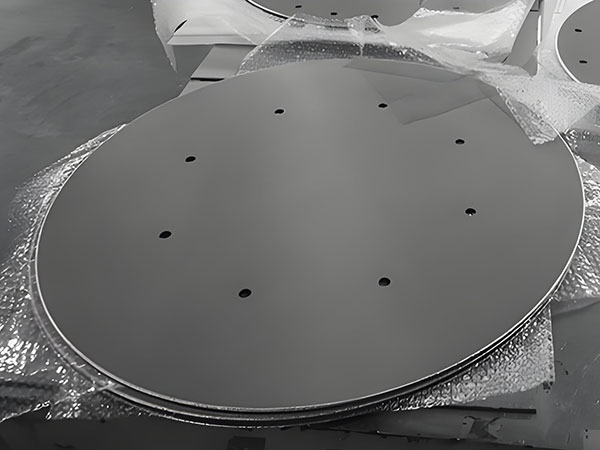

Sintered metal mesh filter disc plates are disc-shaped filter elements made of sintered wire mesh screen and support plate or frame. Sintered mesh filter discs can be disc assembly or monolithic. Sintered wire mesh can be welded together with frame plate section. Then the sections are assembled into a disc assembly with bolts. Whereas in monolithic, sintered wire mesh is either welded or sintered together with the entire disc support plate frame and then welded with flanges into a disc assembly.

sintered metal mesh filter disc for nutsche filter in dryer carbinet

Sintered mesh filter discs for agitated nutsche filter/dryers

Sintered metal mesh filter disc plates are mainly used in agitated filter/dryers as bottom filter screens. The disc plate captures solids and forms a filter cake while liquid passes through and flows out. In other applications, the filter disc can be used as an air diffuser. Air flows through the sintered mesh, drying or pushing the solids on the disc.

We offer services for a wide range of sintered mesh nutsche filter disc plates.

assembly type of sintered metal mesh filter disc plate for nutsche filter

monoblock type of sintered metal mesh filter disc plate for nutsche filter

Sintered mesh filter discs for chromatography columns

Another important application of sintered metal mesh disc plates is large chromatography columns. There are two sintered mesh sheets at the top and bottom of the column, one for distribution and the other for supporting the bed and filtering. Some chromatography column suppliers also refer to sintered mesh discs as chromatography frits.

sintered metal mesh filter disc for chromatography column

sintered metal mesh filter disc for chromatography column

Sintered Mesh Filter Discs for Explosion and Fire Protection

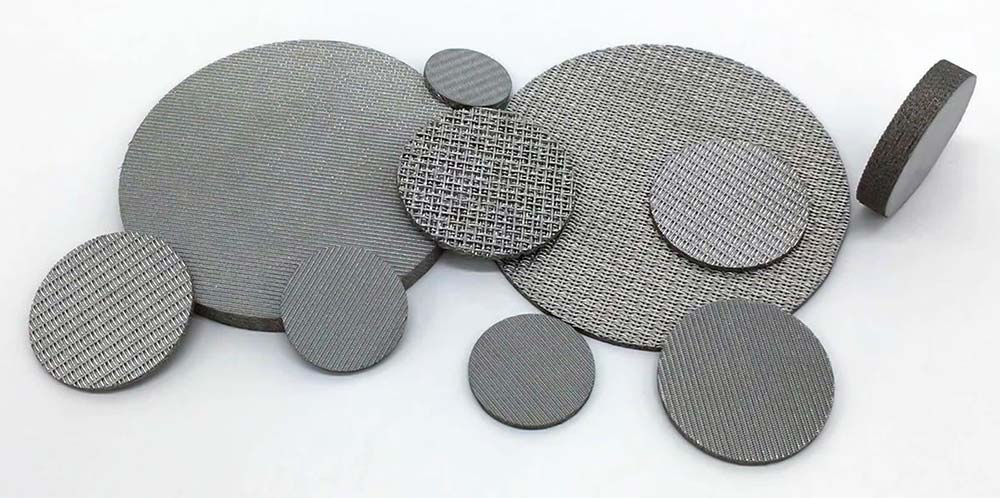

Sintered mesh filter disc plates are good filter elements for protecting equipment like detectors, instruments, sensors from not only harmful particles, but also explosions and flames. The multi-layer porous structure blocks particles, disperses flames and absorbs energy. The sintered mesh only lets cool and clean air/gas pass through the filter disc. In order to precisely control the diameter of the diameter, we use laser or EDM cutting to cut the filter disc from the sintered wire mesh sheet.

sintered mesh filter disc for explosion proof and flame arrest

Sintered Mesh Filter Disc Plates for Extractors

Sintered mesh filter discs are the filter media for the removal of particulates and absorbents during extraction filtration. The filter disc plate can be a bare sintered mesh, or a sintered mesh (spool-shaped filter) welded with double-triple clamp fittings. Typical micron ratings are 1 micron, 5 micron, and 10 micron.

sintered mesh filter disc plate tri-clamp filter spool

Customization of Sintered Metal Mesh Filter Disc Plates

Our micron rating options: 0.5 1 2 5 10 15 20 25 30 40 50 100 150 200 μm. Others on request.

Disc diameters up to 1150 mm for one-piece discs without welds and up to 3000 mm for disc assemblies.

316L (1.4404) stainless steel is the preferred material for filter discs. Hastelloy C276, Hastelloy C22 are the best choices for the most challenging corrosive working environments. Other exotic materials are also available on request, such as 310S, 904L, Monel 400, Inconel 625, etc.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.