Sintered Metal Fiber Felt Filter Cartridges

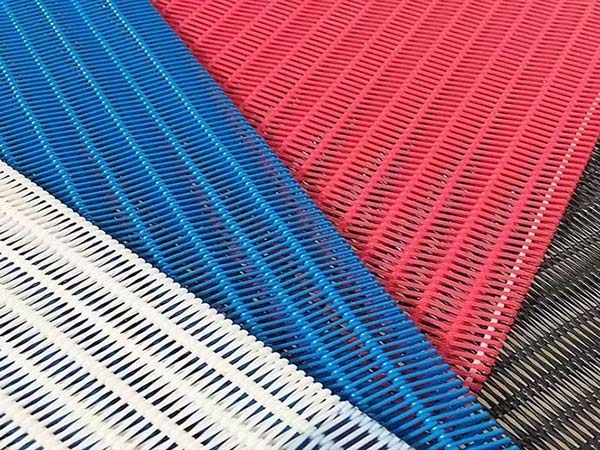

Sintered metal fiber felt filter cartridges are made of random metal fiber felt, cylindrical or pleated. Cylindrical sintered metal fiber cartridges are butt-jointed or joint-welded in the connection area. Cylindrical sintered metal fiber felt is usually metal fiber felt with wire mesh on one or both sides.

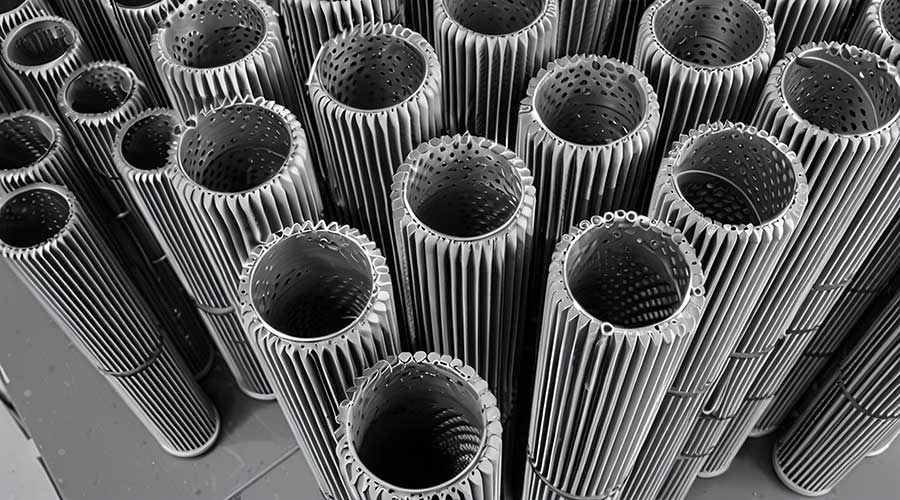

cylindrical type sintered metal fiber felt filter element

Pleated sintered metal fiber felt filter element

For pleated sintered metal fiber cartridges, the metal fiber felt is usually wrapped with square woven mesh on both sides to protect the felt. On the outside of the pleats, there may be a perforated metal sleeve to protect the pleats, or it may be bare if there is no backwash or back pressure working conditions.

sintered metal fiber felt filter cartridges

sintered metal fiber felt filter cartridges with outer sleeve

Outstanding features of sintered metal fiber felt filter cartridges:

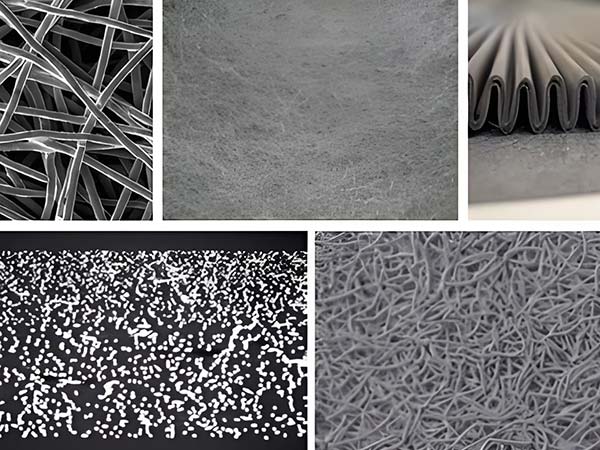

- Extremely high porosity (up to 80%)

- Multi-layer 3D structure

- Deep filtration performance

- Excellent temperature resistance (FeCrAl fiber above 1000℃)

- Higher strength and no ESD compared to glass fiber and other non-metallic filter media

section view of sintered metal fiber felt pleated filter element

Sintered metal fiber felt filter cartridges specifications:

|

Absolute Rating μm |

Bubble Point Pressure

Pa |

Average Air Permeability

l/dm2/min |

Thickness

mm |

Weight

g/m2 |

Porosity

% |

Dirt Holding Capacity mg/cm2 |

| 3 | 12300 | 9 | 0.35 | 975 | 65 | 6.40 |

| 5 | 7600 | 34 | 0.34 | 600 | 78 | 5.47 |

| 7 | 5045 | 57 | 0.27 | 600 | 72 | 6.47 |

| 10 | 3700 | 100 | 0.32 | 600 | 77 | 7.56 |

| 15 | 2470 | 175 | 0.37 | 600 | 80 | 7.92 |

| 20 | 1850 | 255 | 0.49 | 750 | 81 | 12.44 |

| 25 | 1480 | 320 | 0.61 | 1050 | 79 | 19.38 |

| 30 | 1235 | 455 | 0.63 | 1050 | 79 | 23.07 |

| 40 | 925 | 580 | 0.66 | 1200 | 77 | 25.96 |

| 60 | 630 | 1000 | 0.70 | 750 | 87 | 33.97 |

Specifications are based on Bekipor AL3 metal fiber porous filter media. Other types of sintered metal fiber felt, such as Bekipor BL3 CL3 CL4, are also available on request.

bekaert sintered metal fiber felt

sintered metal fiber felt – random laid metal fiber

Sintered metal fiber felt filter cartridges achieve high flow rates while maintaining excellent dirt holding capacity. Due to their porous structure, they are easily cleaned by backwashing.

The standard material for sintered metal fiber is 316L stainless steel. However, on request, highly corrosion-resistant Hastelloy sintered metal fibers and high-temperature resistant Inconel, FeCrAl sintered metal fiber meshes are also available.

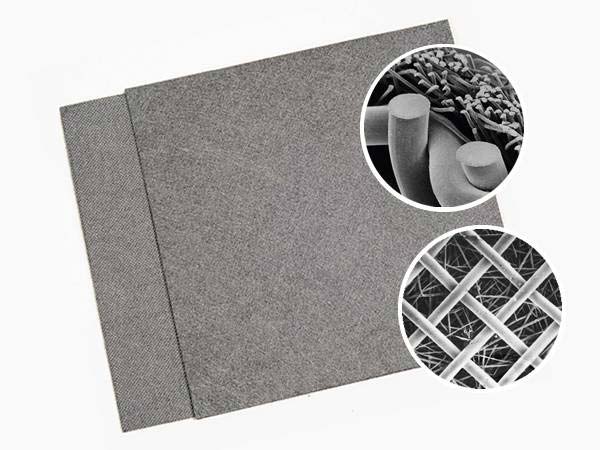

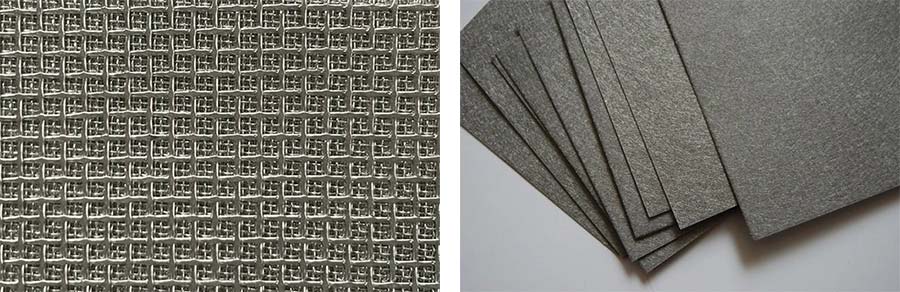

Sintered metal fiber felt with protective mesh for more severe working conditions

The protective mesh can be sintered together with the ordinary sintered metal fiber felt to provide additional support and higher strength. The protective mesh can provide support at the bottom or support and protection for cylindrical filter elements on both sides.

metal fiber with protection mesh vs sintered metal fiber felt coarse

Typical applications of sintered metal fiber felt filter cartridges:

- Replacement of glass fiber filters for oil and fuel filtration

- Polymer melt filters and other high viscosity fluid filtration

- High temperature gas/air dust removal or steam filtration

Sintered Metal Fiber Felt Filter Cartridges and top quality sintered metal fiber felt made in China are available on request.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.