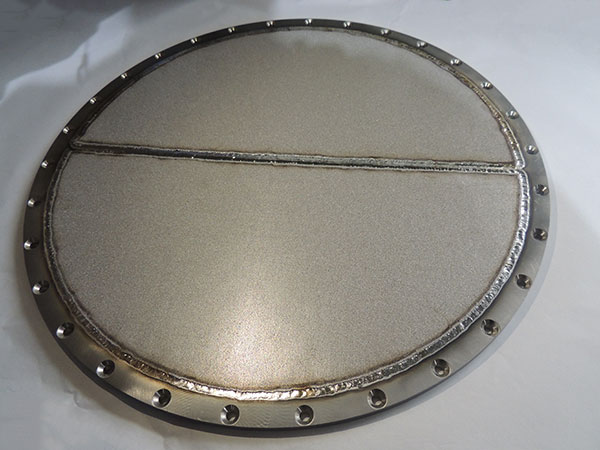

Sintered Metal Fiber Felt

The sintered metal fiber felt is a specialized type of porous material used in various industrial applications. It is made by compressing and sintering layers of metal fibers to create a structure with interconnected pores. The sintering process involves heating the fibers to a temperature below their melting point, causing them to bond together.

The metal fibers used in sintered metal fiber felts are typically made of materials such as stainless steel, bronze, nickel, or other alloys. The choice of metal depends on the desired properties of the final product, such as corrosion resistance, temperature resistance, or chemical compatibility.

Materials of Sintered Metal Fiber Felt

Sintered metal fiber felts are made from various types of metal fibers, and the choice of materials depends on the specific requirements of the application. Some common materials used in the manufacturing of sintered metal fiber felts include:

- Stainless Steel: Stainless steel is a popular choice due to its excellent corrosion resistance and durability, commonly used grades include 316L, 316, 304, etc. It can withstand exposure to various chemicals and high-temperature environments.

- Pure Nickel: Nickel-based alloys are used when superior corrosion resistance is required, particularly in harsh chemical environments or applications with extreme temperatures.

- Bronze: Bronze offers good mechanical strength, thermal conductivity, and corrosion resistance. It is often used in applications where stainless steel may not be suitable, such as situations involving highly acidic or alkaline environments.

- Inconel: Inconel is a specific type of nickel-chromium-based superalloy that offers exceptional resistance to high temperatures, oxidation, and corrosion. It is commonly used in aerospace and high-temperature applications.

- Hastelloy: Hastelloy is another nickel-based superalloy known for its outstanding corrosion resistance in highly corrosive environments containing acids, chlorides, and other aggressive substances.

- Copper: Copper-based sintered metal fiber felts are used in applications requiring good electrical conductivity and thermal conductivity.

- Titanium: Titanium offers excellent corrosion resistance and is often used in applications where weight is a critical factor, such as in aerospace or marine environments.

Stainless Steel Fiber Felt

Sintered Fiber Felt

Stainless Steel Sintered Felt

The high-temperature resistant metal fiber felt is vacuum sintered from Fe-Cr-Al alloy fiber. Because the material has excellent high-temperature resistance and oxidation resistance, it is an ideal material for application in harsh environments. It is widely used in the fields of catalyst carrier materials, burners, and high-temperature hot gas dust removal.

The multilayer metal fiber felt of graded aperture, formed by layers with different fiber diameters, can realize higher filtration accuracy than single-deck felt. At the same time, it can be pleated to increase the available filtration area, thus further increasing the dust capacity. The sintered metal fiber felt is a depth-based filtration medium, which can remove pollutants by capturing the particles in a filter medium structure.

Filter Fineness / Filter Rating

Sintered metal felts are available in a wide range of filter ratings, from coarse to fine. Some common filter ratings for sintered metal felt include 1 micron, 5 microns, 10 microns, 20 microns, and higher. Specialized applications may require even finer filter ratings, and manufacturers can provide customized solutions based on the desired level of filtration efficiency.

| Specifications of Stainless Steel Sintered Felt | |||||||

|---|---|---|---|---|---|---|---|

| Model No. | Absolute Rating, μm | Bubble Point Pressure, Pa | Average Air Permeability, l/dm2/min | Thickness, mm | Weight, g/m2 | Porosity, % | Dirt Holding Capacity, mg/cm2 |

| SFF3 | 3 | 12300 | 9 | 0.35 | 975 | 65 | 6.4 |

| SFF5 | 5 | 7600 | 34 | 0.34 | 600 | 78 | 5.47 |

| SFF7 | 7 | 5045 | 57 | 0.27 | 600 | 72 | 6.47 |

| SFF10 | 10 | 3700 | 100 | 0.32 | 600 | 77 | 7.56 |

| SFF15 | 15 | 2470 | 175 | 0.37 | 600 | 80 | 7.92 |

| SFF20 | 20 | 1850 | 255 | 0.49 | 750 | 81 | 12.44 |

| SFF25 | 25 | 1480 | 320 | 0.61 | 1050 | 79 | 19.38 |

| SFF30 | 30 | 1235 | 455 | 0.63 | 1050 | 79 | 23.07 |

| SFF40 | 40 | 925 | 580 | 0.66 | 1200 | 77 | 25.96 |

| SFF60 | 60 | 630 | 1000 | 0.7 | 750 | 87 | 33.97 |

Features of Sintered Metal Fiber Felt

- High Porosity: Sintered metal fiber felt has a high porosity, typically ranging from 70% to 95%. This allows for efficient filtration and fluid distribution with minimal pressure drop.

- Interconnected Pores: The sintering process creates a three-dimensional network of interconnected pores. This interconnected structure enhances the flow of fluids and gases through the material.

- Uniform Pore Size Distribution: The manufacturing process ensures a uniform distribution of pore sizes throughout the material, providing consistent performance and filtration efficiency.

- Wide Temperature Range: Sintered metal fiber felt can withstand a wide range of temperatures, depending on the materials used in its construction. Some variants can operate in extremely high-temperature environments.

- Chemical Compatibility: The choice of metal fibers allows for excellent chemical compatibility, making sintered metal fiber felts suitable for use with a variety of corrosive substances.

- High Filtration Efficiency: The small and uniform pore size of the material allows it to effectively capture and retain solid particles, making it a reliable filtration medium.

- Mechanical Strength: Despite its high porosity, sintered metal fiber felt retains good mechanical strength, enabling it to withstand high pressures and mechanical stresses.

Application Areas

- Filter powder and gather particles from the vacuum and compressed airlines.

- Filter the polymers, such as polyamide, polyester, polypropylene, polyamide, nylon

- The air filter of automobiles, lubricant filter, gasbag aerator, recycling of chemicals, and catalyst

- Hydraulic pressure and fuel

- Burner: it is made of heat-resisting alloy, and sintered metal fiber is used as radiation material for burner application.

- Refinery: high flow rates of continuous operation in refinery application

- Mesh: the non-woven metal fiber is used for the separation system of liquid-liquid separation(coalescence and liquid-gas separation (demist) )

- Food and drink-process steam filtration, hydrogenation reactor catalyst recycle, polish syrup, wine, and other liquids, remove the catalyst from spice elements and other food industries, the activated carbon extraction and color removal.

- Nucleus ventilation

- Filtration of HEPA and ULPA

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.