Sintered Mesh Strainer Basket Filter

Strainer basket filter, also known as replacement filters, are made of perforated or woven wire mesh. They can be categorized into standard filter baskets and angled filter baskets. Mesh filter baskets are available in various levels of mesh and micron requirements. To maximize the available surface area of the filter basket, the holes are perforated in a staggered pattern. All types of filter baskets have a lift-up handle and a sturdy flat bottom. They offer high liquid capacity and high flow rates.

sintered mesh filter basket strainer with grip band

sintered mesh filter basket strainer with hand grip bar

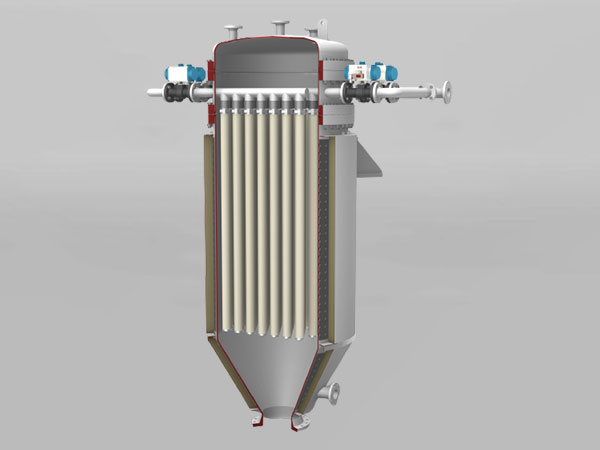

Sintered mesh strainer basket filters are primarily used for coarse filtration with low contamination, but may be used at high pressures. The direction of flow is usually from the inside out, so dirt/impurities can be filtered through the sintered metal mesh basket and then easily removed during maintenance or automatic backwashing. Strainer basket filters are absolutely washable and reusable.

Specification of Strainer Basket Filter

Material: ss 302, 304, 304L, 316, 316L, etc.

Types: Standard filter baskets and inclined filter baskets.

Filter media: perforated or woven mesh.

Mesh: 20, 30, 40, 50, 60, 70, 80, 100, 150, 200.

Micron wire mesh: 40, 90, 160, 250 for industrial use, 5, 10, 15, 25 for light special use. Perforation sizes: 1/2“, 3/8”, 1/4“, 3/16”, 9/64“, 3/32”, 1/16“, 3/64”.

Diameter and length: customized upon request.

As far as piping systems are concerned, filters are very important for the protection of equipment such as pumps, meters, valves and other mechanical components. Prevent potential damage caused by impurities and other foreign particles carried by process fluids (oil, water, etc.).

Sintered wire mesh with perforated metal plate is the most commonly used material for strainer basket filter. Since this C-shaped sintered mesh is self-supporting and easy to form, and it can withstand higher pressures than ordinary mesh spot welded wire mesh.

Because the mesh layers are fused at the contact points, sintered mesh baskets are ideally suited for use in strainer basket filters where backpressure conditions may exist. The mesh will not separate from the perforated tube as the fluid flows backwards from the outside to the inside.

sintered mesh strainer basket filter

sintered metal mesh filter basket strainer

Customization of Sintered Mesh Strainer Basket Filters

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are standard materials for sintered metal mesh filter basket filters.

Other exotic materials such as 310S, 904L, Hastelloy C276, Hastelloy C22, Monel 400, Inconel 625, etc. are available upon request.

Hardware/end fitting materials can differ from sintered metal mesh.

stainless steel filter basket strainer

stainless steel porous slanted mouth basket filter

Characteristics of Sintered Mesh Strainer Basket Filter

- Exquisite appearance

- Good filtration effect

- High tensile strength

- Acid and alkali resistance

- Excellent corrosion and heat resistance

- Non-toxic and harmless, easy to clean

- Long service life

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.