Sintered Mesh Conical Filter

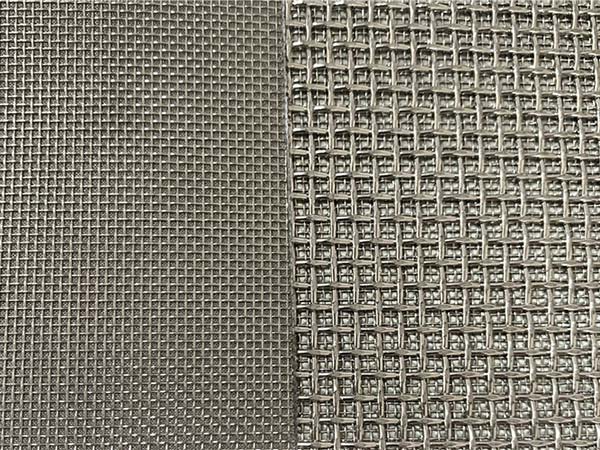

Conical filter is a shaped cartridge made of five-layer sintered mesh or multi-layer sintered mesh welded by laser cutting. The filter is made of multi-layer stainless steel wire mesh superimposed with vacuum sintering. It is characterized by strong corrosion resistance, good permeability, high strength, easy cleaning and backwashing, accurate filtration precision, clean filter material, and non-shedding screen.

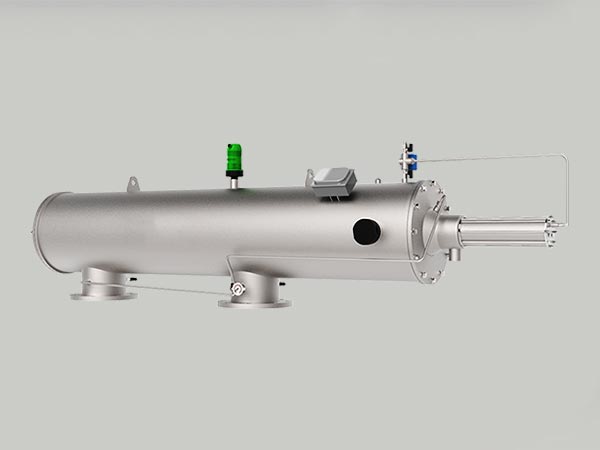

Sintered mesh conical filters are designed to protect expensive pumps, valves, instruments and other mechanical equipment from foreign matter. Conical filters have baskets mounted between metal body flanges and can be used as temporary or permanent filtration devices.

Conical strainers are typically made of carbon steel, stainless steel, and other alloys, and most sizes come with perforations and grids. For ring fittings, specify ring number and style. When ordering, specify the following information: 1) pipe size, 2) pressure rating, 3) perforation or grid size, 4) material, and 5) style.

Truncated Type Conical Strainer

Sintered Mesh Cone Filter

Wire Mesh Conical Filter

Basket Conical Filter

Industrial conical filter is the simplest form of filtration in pipeline coarse filter series, installed on the pipeline can remove the larger solid impurities in the fluid, so as to make the machines and equipments (including compressors, pumps, etc.) work and operate normally, and to achieve the stabilization of the process, to ensure the safety of production.

When the fluid enters the cartridge with a certain screen size, its impurities are blocked, while the clean filtrate is discharged from the filter outlet. When cleaning is needed, just take out the removable filter cartridge and put it back in after treatment. Therefore, it is very easy to use and maintain.

Applications of Conical Filter

Used for filtration of polyester, water treatment, petroleum, pharmaceutical, food and beverage, chemical, chemical fiber products and high temperature air.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.