Porous Metal Membrane Roll

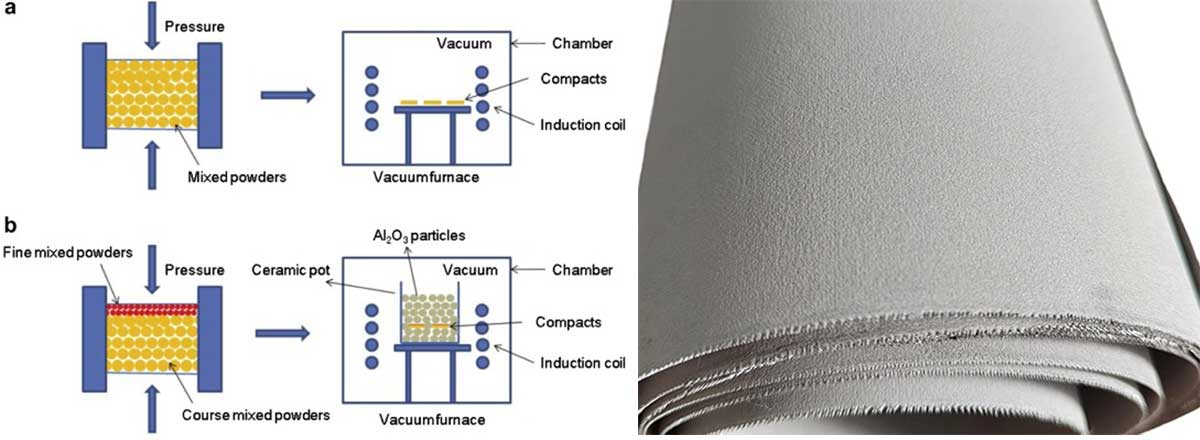

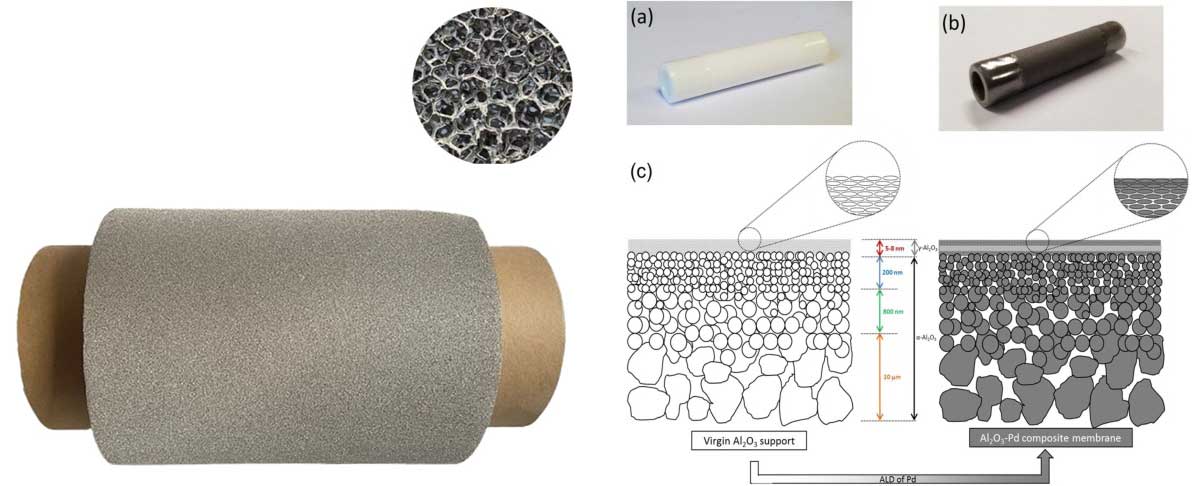

This Excelfilter porous metal membrane roll is produced by a process of compounding metal powder with metal mesh, followed by rolling and solid phase sintering, and its thickness ranges from 0.3-0.5 mm. This synergistic combination of manufacturing technologies not only improves the sintered metal membrane filter roll but also makes it have higher strength and smaller pore size in the micron range.

We can customize porous plates and rolls according to your specific application. This customization allows adjustment of pore size, material selection, thickness and other parameters. If you have specific specifications, data or application requirements, you can communicate with Excelfilter manufacturers to tailor stainless steel powder wire mesh composite porous plates or rolls to meet your needs. This ensures that these filter materials perform optimally under specific environmental and process conditions.

The production process involves sintering ultra-fine stainless steel powder woven wire mesh. Sintering is a method of compacting solid materials into shapes by heating or applying pressure, which is a key step in developing unique properties of metal porous membrane roll medium.

High permeability is one of the main advantages of sintered membrane filter rolls as filter media. The complex weaving of metal wires and sintered ultra-fine stainless steel powder forms a membrane layer that allows fluids or gases to easily pass through the surface of the media while effectively capturing particles or impurities. This makes sintered membrane filter rolls particularly suitable for a variety of industrial hot gas filtration and separation applications.

Metal Porous Membrane Roll VS Sintered Metal Fiber Felts

Smaller aperture size classes and lower cost

- The membrane filter roll medium is made through natural accumulation or pressure molding of metal powder, with a selectable pore size structure ranging from 0.1 to 10 micrometers.

- Although this results in the metal porous membrane roll having slightly lower air permeability compared to metal fiber felts, whose pore size range is typically only between 3 to 80 micrometers, the smaller pore sizes contribute to enhanced filtration efficiency. Additionally, its production and manufacturing costs are relatively lower.

Good backflush cleaning effect

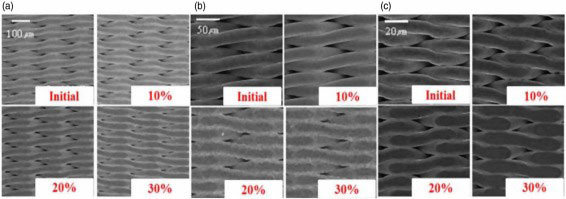

The metal porous membrane roll is made from 10-15 layers of micron-sized metal powder compressed together, with the powder particles ranging in size from 10 to 30 microns. Sintering technology enables the formation of a smooth and robust film layer on the surface of the metal porous membrane, featuring a uniform distribution of pore sizes.

It is particularly suited for microfiltration (MF) and ultrafiltration (UF) separation processes for gases. Capable of withstanding prolonged use and multiple backflush cleaning cycles, this offers users a reliable and durable filtration solution, especially in industrial and laboratory settings where efficient and stable filtration performance is required.

In the filtration mechanism process, interception primarily occurs through surface micropores. When a filter cake forms on the surface, it can be cleaned through online backblowing, allowing the filter cake to easily detach.

With long-term use, the pressure loss is low. In contrast, metal fiber felts act as dirt-accumulating materials. Over time, their pores gradually become clogged with fine dust, making them difficult to clean through backblowing. This leads to greater resistance during prolonged use.

Size of Porous Metal Membrane Roll Technical Data

- Material: 300 series stainless steel, nickel-based high-temperature alloy, Hastelloy alloy, etc

- Dimensions: Width 200-500mm, 20-50m/roll

- Grammage: 1900-2100g/㎡

- Permeability: 35L/dm². Min@200Pa

- Initial pressure: 120Pa

- Aperture: 1-10micron

- Filtration efficiency: 99.999%

Porous Metal Membrane Roll Features And Benefits

- Excellent machinability, weldability, and sealing performance.

- High mechanical strength, usable under high pressures (up to 31MPa) to enhance separation capability.

- Can withstand temperatures up to 315°C with good thermal conductivity and minimal thermal stress, ensuring membrane longevity and reliability without sudden failures.

- Resistant to strong acids and bases, suitable for extreme pH material separation, enhancing adaptability and broadening membrane technology applications.

- Equipped with porous gold film for direct steam sterilization, ensuring aseptic operation.

Applications of Porous Metal Membrane Roll

- Chemical Industry

- Oil Refineries and Petrochemical Plants

- Chemical Pharmaceutical Production

- Wastewater Treatment

- Air Pollution

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.