Polymer Melt Filter Elements

Polymer melt filter elements are essential for all polymer processing processes because there are a lot of impurities in the polymer melt that can significantly affect the quality of the polymer product and even destroy processes such as plastic extrusion, injection molding, film stretching or fiber/filament/monofilament spinning. Stainless steel melt filters can be used to filter various types of molten polymers such as polypropylene, polyester, PC/ABS, low-density polyethylene, high-density polyethylene, polystyrene, thermoplastic elastomers, TPU, polyoxymethylene, polyphenylene sulfide, polyetheretherketone, polyamide, etc.

Polymer melt filter elements are usually made of stainless steel wire mesh or sintered metal fiber. Because these metal filter materials can withstand the high pressure caused by the viscosity of the polymer melt and can be cleaned and reused after washing and cleaning. The cleaning process of polymer melt filters can be grinding cleaning, chemical solvent cleaning, burning/heating.

The micron rating of the filter element varies depending on the application. We can provide wire mesh filters with millimeter pore size for plastic recycling, and we can also produce stainless steel sintered metal fiber pleated filter cartridges with absolute ratings of 3 microns for fibers and films.

Wire Mesh Screen Group for Screen Changer

Polymer extruder screen changer uses wire mesh as filter element. The screen can be single layer, multi-layer spot welded rim/frame mesh disc or even sintered wire mesh.

wire mesh screen pack for screen changer

Leaf Filter Element for Polymer Melt Filtration

Leaf filter element is made of multi-layer wire mesh and sintered metal fiber felt filter media. It is a cross-sectional filter element.

Polymer molten fluid flows in from both sides of the disc surface and flows out from the inner hub to the output pipe. It has internal flow guide and separator. The internal structure is also the support frame of the filter media to withstand the high pressure difference caused by contaminants in high viscosity fluid.

Some common filter grades of leaf disc filter include 5 10 20 30 40 60 80 microns. 7 inches and 12 inches are common outer diameters.

SS 316L sintered metal fiber felt is the default filter media. Others such as wire mesh or laminated sintered mesh are also available upon request.

Other filter grades and diameters can be customized.

Pleated Metal Filters for Candle Filter Changers

Candle filter changers use dozens of pleated wire mesh filter cartridges/sintered metal fiber filter cartridges to increase the filtration area, reduce differential pressure and extend service life.

Screen changers are usually piston-type. That is why the filter candles can have the same diameter, but different lengths.

Pleated Metal Filters for Large Area Polymer Melt Filter Elements

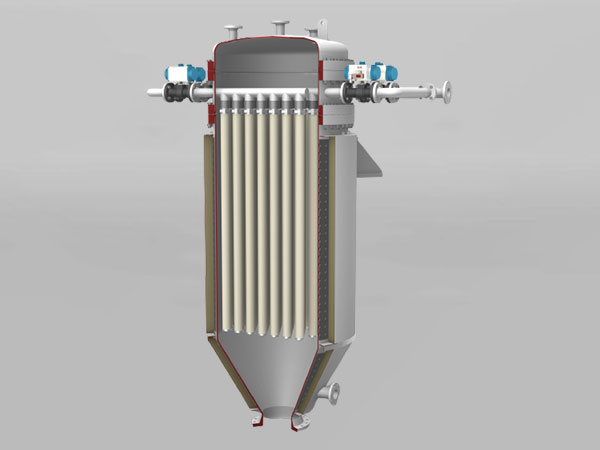

Large area polymer filtration systems are designed for large capacity, high efficiency and high precision applications. These systems usually consist of two filter containers, which can be interchanged and keep the system working continuously.

For normal contamination, large area filter elements are usually pleated wire mesh filter cartridges. Sintered metal fiber filter cartridges will be used for deep filtration of gels and other impurities.

Pleated Metal Filter Cartridge Assemblies with Removable Hardware

Pleated metal filter cartridges can be assembled, consisting of a replaceable filter media body and removable hardware: connectors, inner supports and end fittings. They are characterized by easy disassembly for cleaning and replacement, which reduces procurement and operating costs.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.