Polymer Filter

Excelfiter offers a full range of polymer filter products, including frame filter discs, single-layer and spot-welded filter discs, polymer leaf discs, metal powder filter packs, mesh laminated sintered filter elements and metal non-woven fiber felt sintered filter elements. According to the specific application requirements, various structural shapes such as cylindrical, pleated or leaf-shaped are available for you to choose. In addition, Excelfiter also specializes in high-quality stainless steel filter cartridges to ensure the best filtration performance in different industrial processes.

In the production process of synthetic fibers, films, plastics and other polymer molten materials, polymer filters effectively remove gel contaminants from high molecular weight polymers, improve product quality, increase production efficiency and reduce production costs.

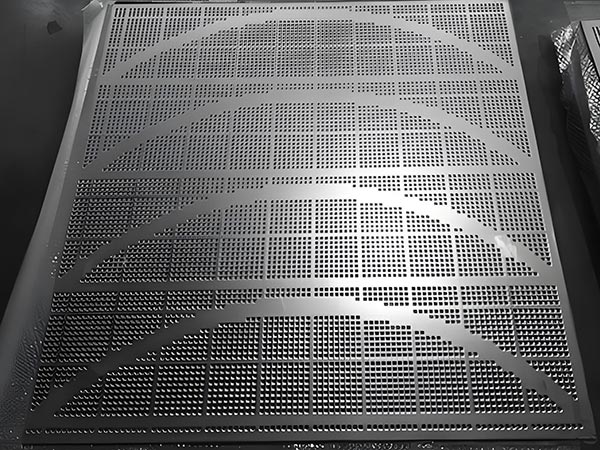

Frame filter disc

The frame polymer filter disc has a multi-layer mesh structure, and each layer has a different mesh size – the layers pass through different meshes to obtain the ideal filtration efficiency. The pleading structure can provide more filtration area.

We provide various configurations and micron levels according to your specific requirements. We can manufacture any shape, choose different frame alloy materials, and integrate them seamlessly into your system.

Technical details and services

- Size range: 5 mm to 450 mm in diameter, special size customization is also supported.

- Multi-layer configuration: Designed and manufactured according to micron size and flow requirements.

Multiple shape options: Standard round, rectangular and other special shapes can be customized. Optional frame alloy materials. - Spot welding package available: Single or multi-layer mesh combination spot welding is available.

- Different filter media options: Metal woven mesh and non-woven fiber felt are standard configurations.

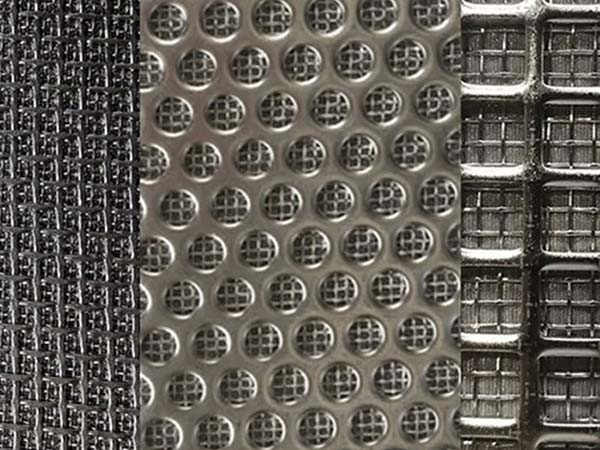

Single-layer spot welding filter disc

This continuous polymer filter also provides single-layer and spot welding mesh discs. With our rich experience and knowledge, we can help you choose the right filter media and structure for your application. Designed for the smooth flow of polymers, ensuring that the polymer is extruded smoothly and efficiently from the system.

Molten polymer systems with high pressure and high flow can also enhance the overall structural stability of the molten polymer filter through the spot welding component manufacturing process. These polymer membrane filters are easy to clean, simplifying the maintenance process, saving time and money.

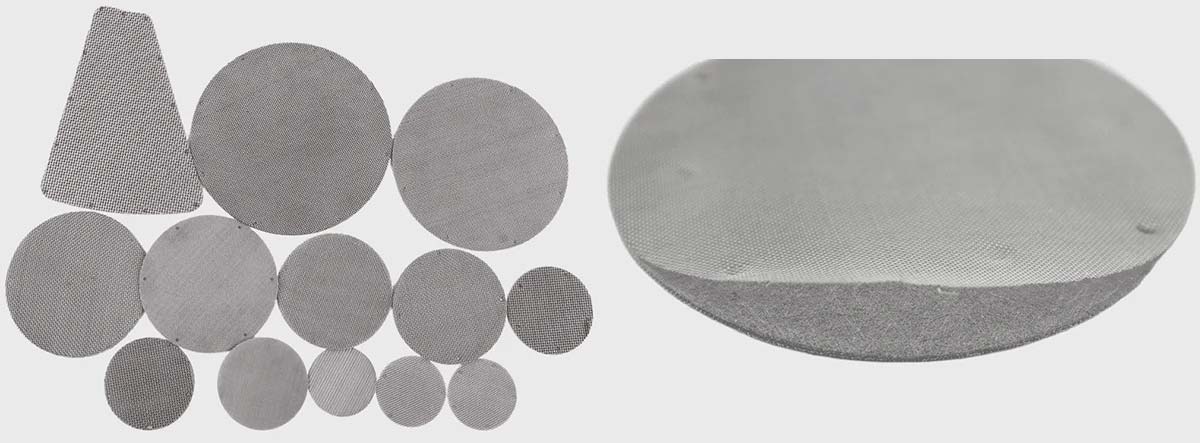

Polymer leaf disc

The polymer leaf disc is made by sintering and laminating multiple layers of metal media. At its center is a hard hub structure hole designed for critical hot melt polymer filtration applications. Polymer membrane filters achieve better gel control by providing smoother flow and are used in polymer melt filter leaf discs.

By combining different filter media configurations, Excelfiter polymer leaf discs can ensure lower pressure drop while achieving longer online life. Its unique structure allows multiple cleanings, reducing the life cycle cost of polymer filtration systems.

Technical Details and Services

- Material: Standard configuration is SS316L or other alloys.

- Standard sizes: 6 inches, 7 inches, 10 inches, 12 inches.

- Micron rating: 3-80 microns available.

- Operating temperature: Can withstand continuous high temperature environments up to 310℃.

- Viscosity: Can meet the filtration requirements of high viscosity liquids up to 260 Pa.s

- Operating pressure: Maintain stable filtration performance at working pressures up to 317 bar, and the maximum working pressure difference can reach 100 bar.

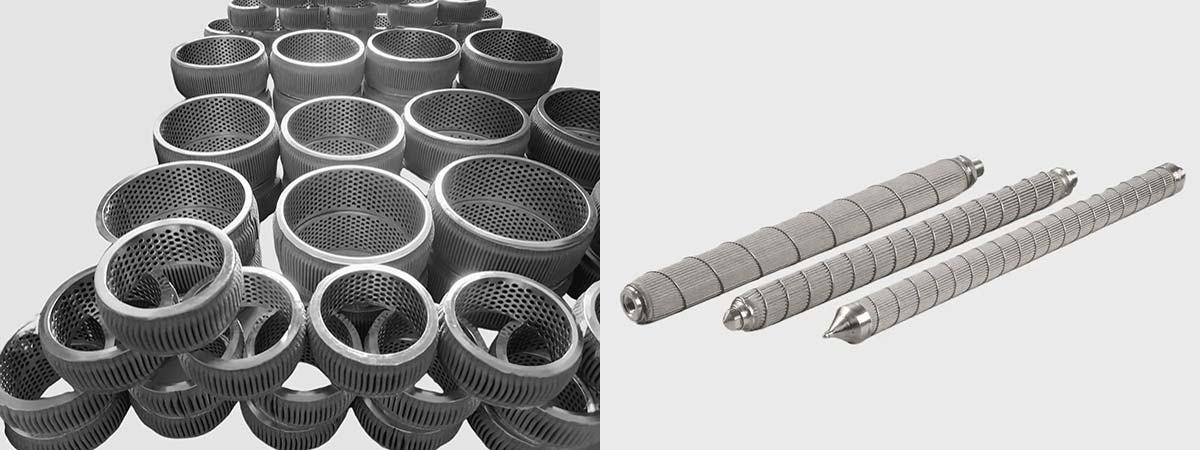

Polymer candle filter

Polymer leaf disc is manufactured by sintering and laminating multiple layers of metal media. At its center is a hard hub structural bore, designed for critical hot melt polymer filtration applications. Polymer film filter achieves greater gel control by providing a smoother flow and retains more gel on the polymer melt filter leaf disc.

Polymer candle filters are available in sizes from 3 microns to 100 microns, and they are typically equipped with an external shroud with perforated plates to protect the media and promote backflow for effective cleaning.

Reduce the internal volume of all polymer filter elements to prevent stagnant flow areas in candle designs. Flow dividers built into the container ensure that the polymer is evenly distributed as it enters the housing.

Our high-strength, high-permeability stainless steel fiber media has a low initial pressure drop and a long service life. This makes it the first choice for industrial polymer melt filter applications.

Technical Details and Services

- Construction: Pleated and Cylindrical

- Material: Standard configuration is SS316L or other alloys.

- Micron Rating: 3-100 microns available.

- Standard Sizes: 10 inches, 20 inches, 30 inches, 40 inches.

- Operating Temperature: Can withstand continuous high temperature environments up to 330°C.

- Viscosity: can meet the filtration requirements of high viscosity liquids up to 260 Pa.s

- Working pressure: maintain stable filtration performance at working pressures up to 317 bar, and the maximum working pressure difference can reach 100 bar.

Metal powder filter pack

The metal powder filter pack is made of stainless steel alloy powder particles with a specific crushed shape. The metal sand in the long fiber and short fiber spinning components consists of two or three layers of metal sand with different particle sizes and quantities. In order to determine the best combination of powder mesh, it is necessary to consider the type of polymer, viscosity, purity, polymerization efficiency, melting temperature and extrusion speed during spinning.

Under high temperature and high pressure environment, the good strength of iron ensures that the particles are not easy to break and minimizes the possibility of spinneret hole clogging. At the same time, the addition of alloying elements such as chromium, nickel, silicon and manganese can enhance the strength of stainless steel particles, maintain high porosity throughout the filtration process, and effectively slow down the growth of differential pressure.

Our metal powder filter filling sand has an irregular shape and a porosity of up to 70-80%, achieving an extremely high surface area. It is very effective in shearing polymer microgels and intercepting foreign matter or impurities in polymer melts. This ensures that the polymer ejected from the spinning assembly is of the highest purity and quality.

When polymer passes through the powder filter media, heat is generated and accumulates locally. However, the good thermal conductivity of the metal sand ensures a high degree of temperature uniformity inside the rotating components.

Accurate control of polymer temperature is essential to prevent capillary breakage and uneven fiber dyeing. Metal powder filter filler sand shows strong resistance to chemical and temperature environments and provides a cost-effective solution for filtering hot polymers.

| Size Mesh | Size Micron | Apparent Density (g/cm3) | Porosity ( % ) |

|---|---|---|---|

| 10-20 | 2000-850 | 1.5 | 75 |

| 20-40 | 850-350 | 1.7 | 73 |

| 40-60 | 350-250 | 1.8 | 71 |

| 60-80 | 250-180 | 2 | 64 |

| 80-100 | 180-145 | 2.1 | 63 |

| 100-120 | 145-125 | 2.3 | 60 |

Polymer filter applications

- Manufacture of PET packaging film, PEEK chips and films

- Polyester bottle chips

- Polyester fibers

- Cellulose acetate fibers

- Nylon 6 and 66 fibers

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.