Polyester Filter Belt

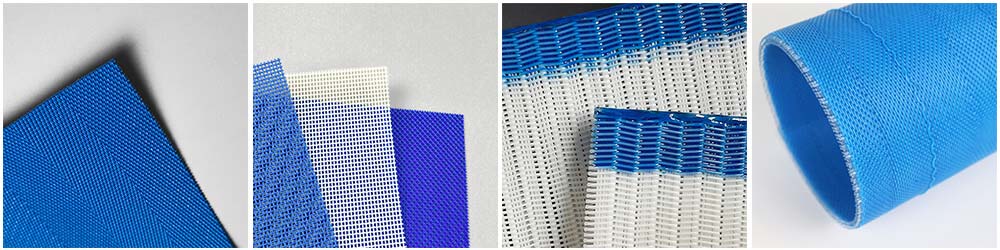

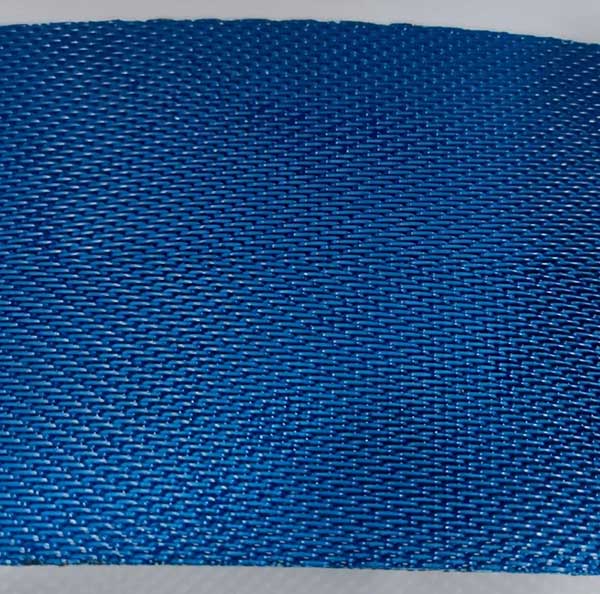

Polyester filter belt is a kind of conveyor belt made of polyester fiber with excellent strength and wear-resistant performance, which is widely used in papermaking, mineral processing, flour, sewage treatment, sugar, pharmaceutical, ceramics, food, printing, coal washing and other industries.

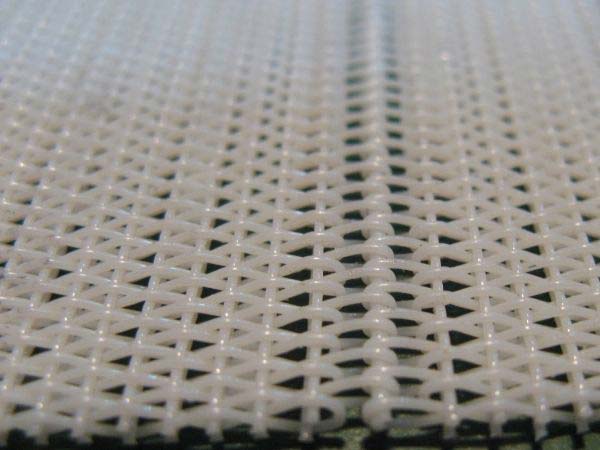

Polyester filter belt adopts the structural form of woven or woven combination (polyester fibers are interwoven through hot pressing combination process), which makes the mesh belt have good stability and carrying capacity, high strength, small deformation, corrosion-resistant, excellent wear-resistant performance, easy to install and use, no interface traces, and long service life.

Type of Polyester Filter Belts

Classified by use: Commonly used are polyester molding mesh, polyester dry mesh, polyester spiral dry mesh, spiral press filter mesh, polyester anti-static mesh, vacuum filter belt, sludge dewatering mesh and so on.

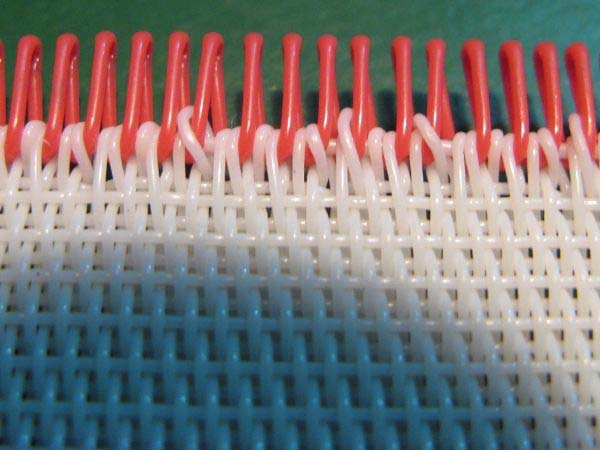

Classification by seams:

single warp-ring seam

pairs warp-ring seam

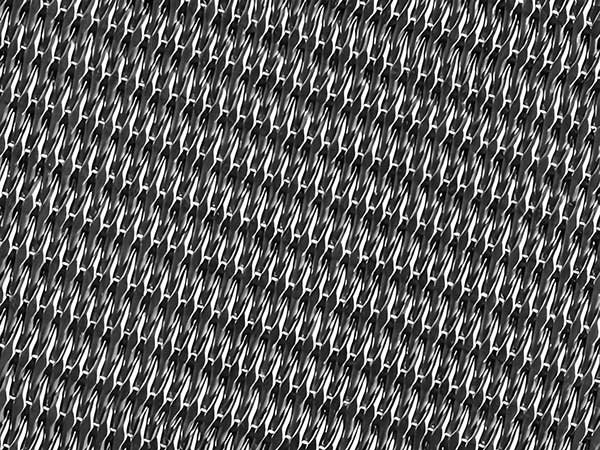

stainless steel clip seam

wrap-ring seam

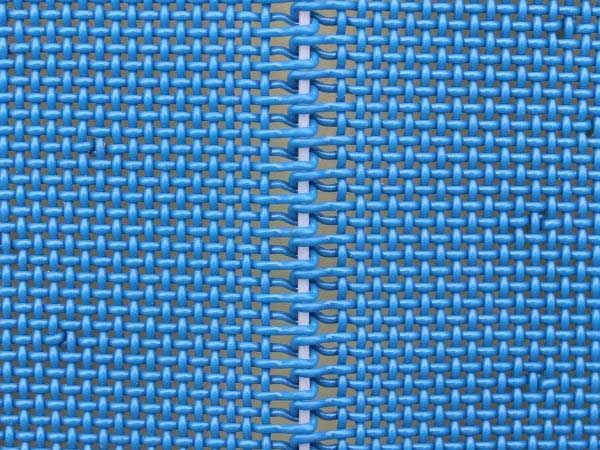

Plug-in spiral ring seam

endless seam (ring belt)

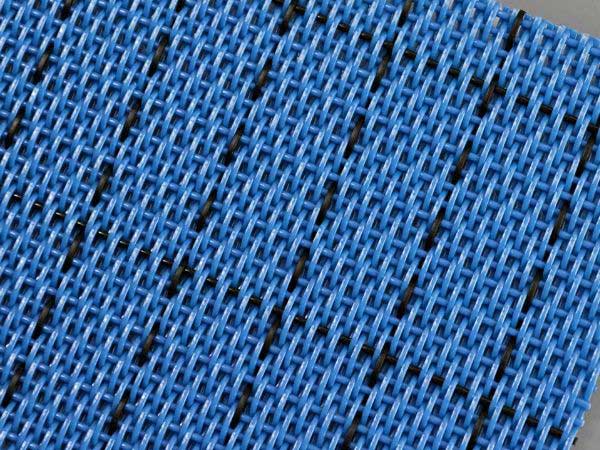

Polyester forming fabrics are commonly used for dewatering in the paper machine forming sector of the paper industry, and are usually composed of warp and weft threads. The warp refers to the longitudinal braid and the weft refers to the transverse braid. The warp threads in paper machines are subjected to high tensions and constant bending and deflection, so the requirements for the warp threads are very strict, and the diameter of the weft threads is usually about 10% larger than that of the warp threads.

Types of polyester forming fabrics

Polyester forming fabrics can be divided into 4-syndicate single-layer fabrics, 5-syndicate single-layer fabrics, 8-syndicate single-layer fabrics, 8-syndicate double-layer fabrics, 16-syndicate double-layer half-layer fabrics, 24-syndicate triple-layer fabrics and so on, according to the type of weaving.

Four, five series of single-layer net is the paper industry standard polyester molding net, mainly used for the production of cultural paper (single glue, double glue, color glue), printing paper, varnished paper, packaging paper, general newsprint and so on. It is suitable for ordinary long mesh paper machine.

Eight single-layer mesh is suitable for the production of large quantities of packaging paper, such as kraft paper, cardboard, corrugated paper, etc., but also for the production of general printing paper, applicable to the general long network paper machine.

Eight-syndicate double-layer net is suitable for the production of high-quality printing paper, including dictionary paper, offset printing paper, newsprint, wrapping paper, etc., but also for the production of thin paper and board paper pulp, liner pulp, core pulp, bottom pulp, etc., applicable to medium and high-speed paper machine.

Sixteen synthesized double-layer half-net for the production of high-quality printing paper, such as offset printing paper, coated paper, newsprint, cigarette paper series (wrapping paper, filter paper), but also for the production of toilet paper, thin paper and board paper pulp, liner pulp, core pulp, bottom pulp, and so on. It is suitable for medium and high speed paper machines.

Multi-synthesized three-layer fabrics are suitable for the production of high-quality printing paper, thin sheet paper, cigarette paper, etc., and are suitable for high-speed paper machines.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.