Pleated Wire Mesh Filter Cartridges

Pleated wire mesh filter cartridges are made of pleated wire mesh filter media. The multi-layer wire mesh is spot welded and then pleated and ironed. The pleats are welded at both ends to form the cylinder body, and then the hardware (end fittings, adapters) are welded to the valve body.

structure of pleated mesh filter cartridge

Structure of pleated wire mesh filter cartridges

The filter layer is usually wrapped in the middle of the inner and outer protective layers. If the filter layer is too fine and easy to deform and damage, an additional transition layer can be added under the filter layer for protection. According to the working and backwashing pressure conditions, the inner support tube and outer protective sleeve can be selected.

Stainless steel pleated wire mesh filter cartridges usually adopt a fully welded structure. This structure will not limit the filter element to the working conditions of glue and additives. The welding method of the pleats is usually plasma welding, and the seam surface is smooth without any leakage. The hardware/adapter is welded by TIG welding and is strong enough and well sealed.

pleated wire mesh filter cartridge detail on welding seam and adapter

Advantages of Pleated Wire Mesh Filter Cartridges

Compared to ordinary cylindrical wire mesh filter elements, pleated wire mesh filter cartridges can achieve:

- Larger effective filtration area

- Higher flow rate

- Excellent dirt holding capacity

- Strong construction for extended service life

Pleated wire mesh filter cartridges are a good alternative to non-metallic filter cartridges because they can withstand higher temperatures and pressures and can be backwashed and reused for steam, hot air and liquid filtration.

pleats of pleated mesh fitler cartridges (large capacity)

pleats of pleated mesh fitler cartridges

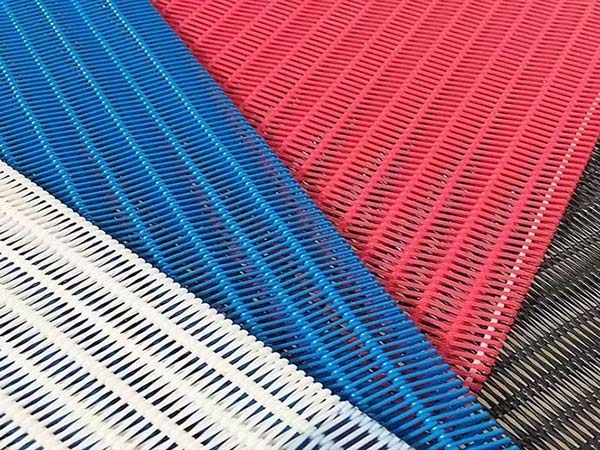

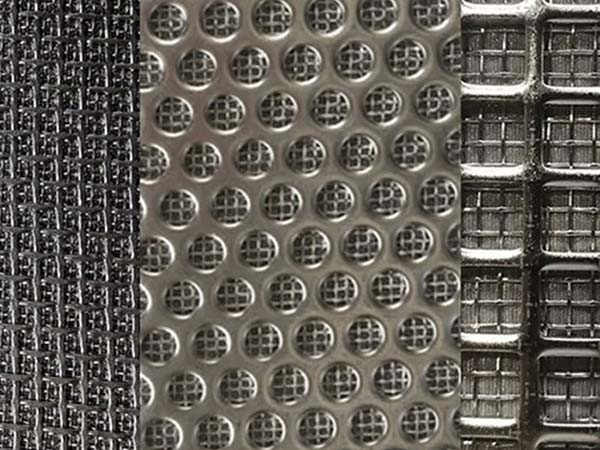

Other filter media for pleated mesh filter cartridges

For deep filtration requirements, the filter layer can be replaced with sintered metal fiber felt because felt is also suitable for pleating.

Custom sintered wire mesh laminates can also be made into pleated filter cartridges. Pleated sintered mesh filter cartridges eliminate the gaps between ordinary pleated mesh filters, thereby avoiding impurities clogging the gaps and making the filter cartridge easier to clean.

pleated mesh filter cartridges on stack

pleated mesh filter cartridges DOE with spiral spring

Material selection for pleated wire mesh filter cartridges

The hardware/end fitting materials of the wire mesh may be different.

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are standard materials for pleated wire mesh filter cartridges.

Other exotic materials are also available upon request, such as 310S, 904L, Hastelloy C276, Hastelloy C22, Monel 400, Inconel 625, etc.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.