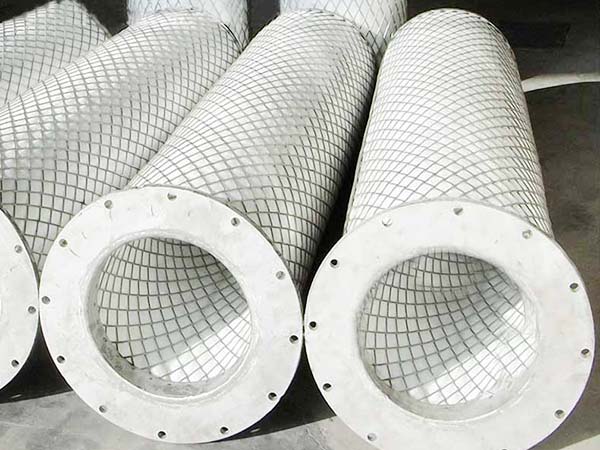

Pleated Mesh Filter Candle

The material of pleated mesh filter candle are stainless steel wire mesh and stainless steel sintered fiber felt,the filter with pleated mesh shape has high dirt holding capacity because the filter area increase much,it is three layers diffent mesh size stainless steel woven mesh,so make the pleated filter not easy to fall off and clean fast.

Pleated mesh filter candles are widely used in various industries for their exceptional filtration efficiency and durability. The pleated candle filters, also known as stainless steel pleated filter cartridge, can be customized in terms of dimensions, materials, and various end connection types to meet your specific requirements. Compared to the high-cost sintered fiber felt materials, the low-cost materials like woven metal wire mesh for pleated metal mesh filters enable customers to save on production costs and generate more significant economic benefits.

Pleated Wire Mesh Filter Double Opening Type

Stainless Steel Mesh Pleated Filter Cartridge Standard connector Type

Pleated Metal Filter Element Quick Release Connection Type

Stainless Steel Mesh Pleated Filter Cartridge Thread connection Type

Excelfilter works closely with many original equipment manufacturs to analyze customers’ designs, parameters, and data requirements. Provide customized recommendations for different filter system applications to ensure that the selected pleated wire mesh filter fully meets the design requirements, and parameters, and matches the data analysis.

Configuration

In order to meet different working conditions and specific installation requirements, metal mesh filter provides users with customized designs. The standard configuration components are as follows.

Standard connector

- Snap coupling

- Thread connection

- Flange connection

- Rod connection

- Double Open End

- Single Open End

Technical Details

Filter rating: 3um to 60um

Temperature: below 450°C

Different media options: From 2-layer to 4-layer mesh configurations, standard options include metal woven mesh and non-woven fiber felt

Materials of construction: SS304/316/316L, also Alloy ( Hastalloy276, Inconel 600, Monel, Titanium, Duplex, and so on)

Gaskets: PTFE, Buna-N2, Graphite composite

Applications: polymer, gas, liquid filtration

Pleated Wire Mesh Filter Element Laser Engraving Encoding

Metal Filter High Temperature Fumigation Cleaning

Benefits of metal mesh filter

- Flexible Configuration: We can provide different aperture sizes, dimensions, and end connection methods.

- Rapid production: Can be produced within 7 days for standard end connection and sealing configurations.

- Mesh Pattern: The filtration layer of the pleated metal mesh filter can be optionally woven in different styles according to your specific application, including square weave, twill Dutch weave, and plain Dutch weave. It also offers a variety of mesh sizes for users to choose from, allowing for a more robust structure when required in applications.

- High contaminant capacity: The pleated structure can trap more pollutant particles to reduce frequent replacement and maintenance. Prolong the service life of pleated wire mesh filter cartridges.

- High Collapse Pressure Rating: After validation design and testing, it is capable of withstanding collapse pressures ranging from 300 to 6,000 PSID. Ensuring the safety of the fluid system.

- Compatibility: Compatible with various liquid or gas media, suitable for operation in harsh environments (including corrosive conditions, high-temperature synthesis gases, or high differential pressures).

- Product Traceability: Each pleated wire mesh filter cartridge is provided with laser-engraved numbering, and entered into a product traceability system for simplified tracking and management.

- Pleated cylindrical cartridges repeatable cleaning: Multiple cleaning methods are available, depending on the contamination level of the metal mesh filter and the type of fluid medium. You can select different cleaning processes, such as high-temperature fumigation, chemical cleaning, and ultrasonic.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.