Perforated Metal Filter Stainless Steel

Stainless steel Perforated Metal Filter is a filter element made by perforating a metal sheet or part. Perforated metal has holes in round, square, hexagonal or other shapes. These holes are arranged in a certain pattern at a specific pitch and angle. Then the diameter and pattern of the holes determine the open area.

perforated metal sheet square and round hole

Perforated Metal Tubes

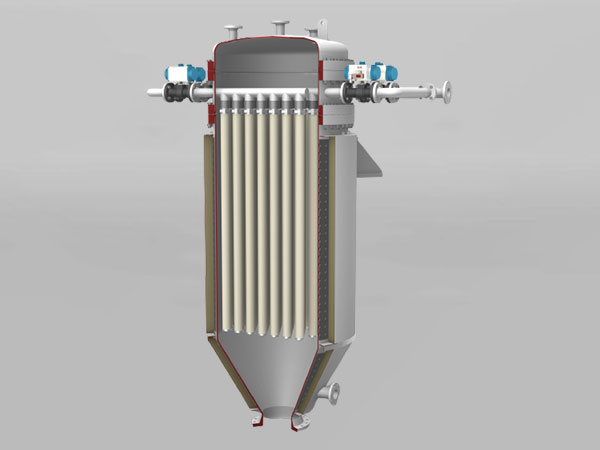

Perforated metal tubes are widely used in coarse particle filters. High-pressure filtration in oil and water well drilling applications usually uses large-size and thick metal tubes. Filter screens can also use perforated metal tubes because of its simple structure and can work in a wide range of filtration grades and pressures.

perforated metal tube for drill well

perforated metal filter tube for strainer

Porous Metal Fibers for Filter Element Support and Protection

Perforated metal tubes are also an important part of some filter elements. For example, in stainless steel pleated filter elements, perforated metal tubes can be used as support cones inside and protective sleeves outside. The inner tube is often round holes and the outer tube is square holes.

Non-metallic filter elements can also use perforated metal tubes for support and protection. Yarn/wire wound filters use perforated metal tubes as inner cones, and many hydraulic or oil filters use perforated metal tubes as outer jackets.

perforated metal tube for pleated stainless steel filter element

perforated metal tube for pleated stainless steel filter elements

Spiral welded perforated metal tube

Spiral welded perforated metal tube is made by winding and welding perforated metal strip. It can flexibly make filter tubes of various diameters. It has good strength and can save costs.

Circular hole spiral welded perforated tube is common. But there are also square hole spiral welded perforated metal tubes with larger opening area.

spiral welded perforated metal tube round hole

sprial welded perforated metal tube with square hole

Drilled seamless tube

Drilled seamless tube is another type of perforated metal tube. It is made of seamless metal tube. The holes are drilled by laser beam or machine drilling. Seamless perforated tube has no risk of weld failure and is the first choice for critical and high-pressure applications.

drilled seamless tube perforated metal tube

Perforated metal disc

Perforated metal disc is a metal disc with perforations. Some semi-automatic coffee machines have perforated metal discs as coffee filters. Such discs are usually thin, have small holes, and are made by etching.

Larger thickness perforated metal discs are often found in extractors or nutsche filters. Such metal discs can serve as a support for other finer filter media or can be sintered with fine mesh to form sintered wire mesh discs. Perforated metal can significantly increase the pressure resistance of these filter systems.

Laser Drilled Filter Discs

Laser drilled filter discs are perforated metal with a depth to aspect ratio of up to 20. Aspect ratio is the ratio of hole depth (metal thickness) to hole diameter. For example, a 2mm thick filter disc can have 100 micron perforations. This high ratio gives laser drilled metal discs greater strength and simpler construction than other wire mesh filter discs. Typical applications for laser drilled filter discs are screen filtration polymer filtration.

Perforated Metal Filter Cones

Porous metal filter cones have a larger filtration area than disc-type ones. It can be used for coarse filters.

perforated metal filter cone with flange

Rasp Hole Conical Mill Screens

Rasp holes are also called rub holes. This is a special perforation with a bulge on one side to create a rasp to tear or cut through material. Rasp Hole Conical Screens are a mill option for product recovery or rasp grinding.

Perforated Metal Baskets

Perforated metal filter baskets are another application for perforated metal. Basket filters can collect particles/items in the basket while letting liquid pass through the holes. This is popular in winemaking and brewing.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.