Industrial Candle Filter

What is a filter candle? Candle Filter is a streamlined industrial tool that is primarily used to filter liquids with minimal solids. It excels at generating high yields, discharging dewatered filter cake, and managing a wide range of filtrates. The tool is particularly effective in filtering flammable, toxic or corrosive media.

Designed with stringent production processes in mind the filtration candles can run continuously, circulating and filtering without interrupting the system, thus minimizing downtime and ensuring operational safety. As pressure filters working in intermittent cycles, industrial candle filters are used in the following areas titanium dioxide treatment, high temperature flue gas treatment, brine clarification, refining chemicals and any process that requires effective separation and removal of filter cake.

Principle of Industrial Candle Filter

When the slurry is pressed into the pressure vessel, the direction of the slurry is always from bottom to top. This facilitates the settling of solid particles in a uniform suspension on the surface of the filter rods, ensuring the formation of a consistent filter cake.

Filter cake is formed on the outer surface of each of the stainless steel candle filter elements. Each row of filter candles is connected in series and parallel to the top as per the design requirements. This design is based on the results of the process requirements.

The discharge pipe for the slurry is connected to a leveler, and each leveler pipe is connected to the main branch through an electric valve. The electric valves control filtration and backwashing and each valve optimizes the formation of filter cake in the filter candles by controlling the flow rate on-line. All header pipe slurries are transported to the main branch line via electric control to form a circular filtration process.

Components of a candle filter

- Vessel housing

- Vessel housing with conical bottom for filtering and polishing the filter cake

- Vessel with concave bottom for thickening the slurry

- Candle-shaped filter elements

- Discharge mechanism for filter cake

- All these components can be made of unique construction materials and fulfill the process requirements.

How to choose a candle filter element?

Each candle-shaped filter element consists of a cylindrical porous support structure. The universal filter media is mounted on a metal stamped support structure and clamped into place. This rigid design allows for high pressure filtration.

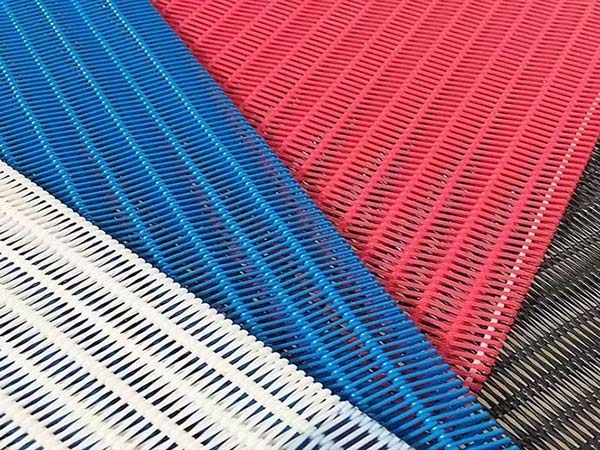

The replaceable filter media can be any woven or sintered material consistent with the filter. A variety of filter media is available, such as stainless steel porous sintered metal tubes, sintered metal composite woven mesh screens, synthetic filter cloths, etc. The media can be customized to suit the design and the candles. The media can be selected based on the design and the purpose of the candle filter.

Reference factors for selecting industrial candle filters

When the space required is limited and a large filtration area is needed.

Vacuum may not be available for filtrate evaporation.

When high clarity filtrate is required for polishing applications.

When toxic and flammable cakes pose a risk of environmental harm, special safe discharge mechanisms may be added.

When the filtrate cake can be dried or discharged as a thickened slurry.

Candle Filter Design

Industrial candle filters are available in various sizes to remove solid particles larger than 0.5 microns. The more significant types can have a filtration area of 60 square meters and contain 112 or more filter elements installed in vessels with diameters of 2.5 to 3.0 meters. Although there is a wide range of operating pressures, most candle filters operate at 8 bar.

- Candle area (square meters) 0.34 to 60

- Filtration accuracy (micron) 0.5-200

- Design pressure (MPa) 0.6. 1.0.1.6

- Cake thickness up to 35 mm

- Setting temperature(℃) 80℃~260℃ Mainly depends on the material

- Product material SUS304, SUS316L

Industrial Candle Filter Application Solutions

Excelfilter Candle Filter manufacturers can provide individual candle filters or complete candle filters. All of our candle filters are custom designed to meet the needs of each customer’s application.

Easy to transport and assemble due to modular design. All products are made in China with competitive price, short lead time and good service. With excellent design and full technical support, filtration can be easily carried out from all aspects.

This technology has a proven track record of reliable performance in a wide range of applications. Excelfilter Candle Filter is commonly used in:

- Pharmaceutical filters

- Fine chemical filters

- Food industry filters requiring FDA approval

- Fuel and oil additive filters

- Hazardous substance filters

- Precious metal and other catalyst recovery filters

- Solids content: up to 2 percent

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.