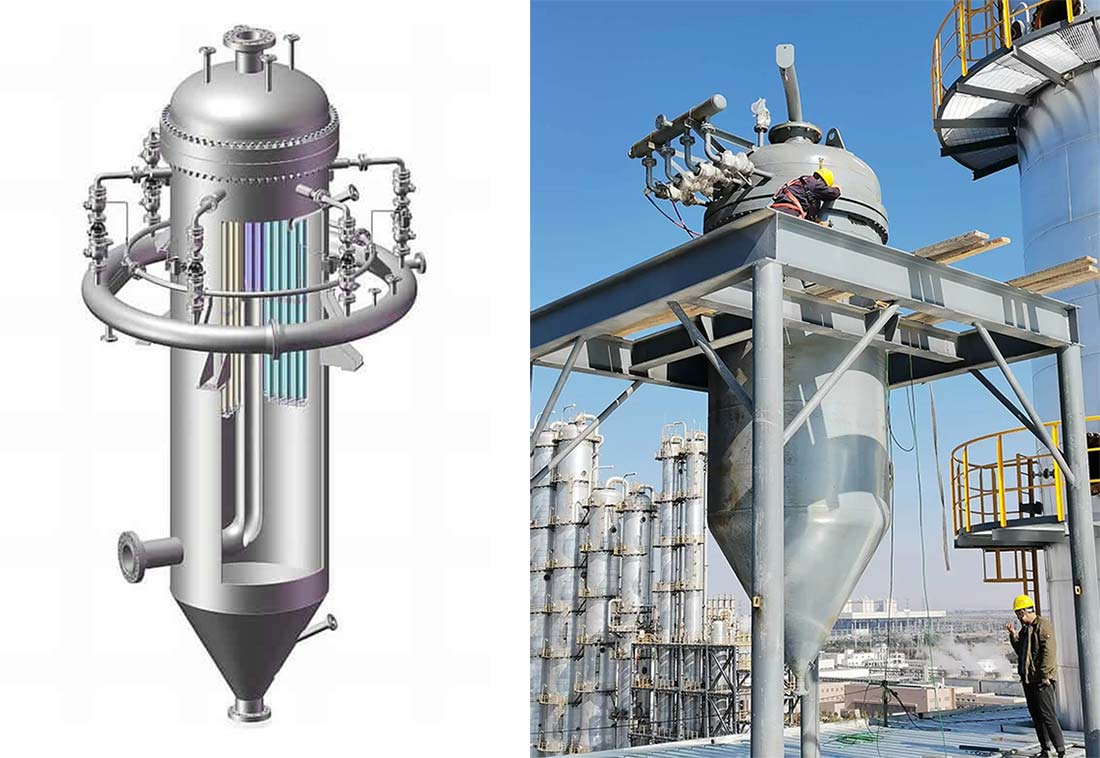

Hot Gas Filter

Hot gas filter usually filter at operating temperatures above 260°C (500°F), and traditional filter media are no longer used for such high-temperature gases. The industrial pulse hot gas filters developed by Excelfilter are mainly used to provide solutions in the fields of industrial high-temperature flue gas waste heat utilization and high-temperature gas purification and recovery. Since the filter medium adopts composite metal fibers to directly purify the high-temperature gas, the collected dust particles are removed from the surface of the filter element. In fact, this process is usually carried out when the hot gas industrial dust collector is online, except for very small pressure peaks (or “overpressure”), it will not interrupt or interfere with the process.

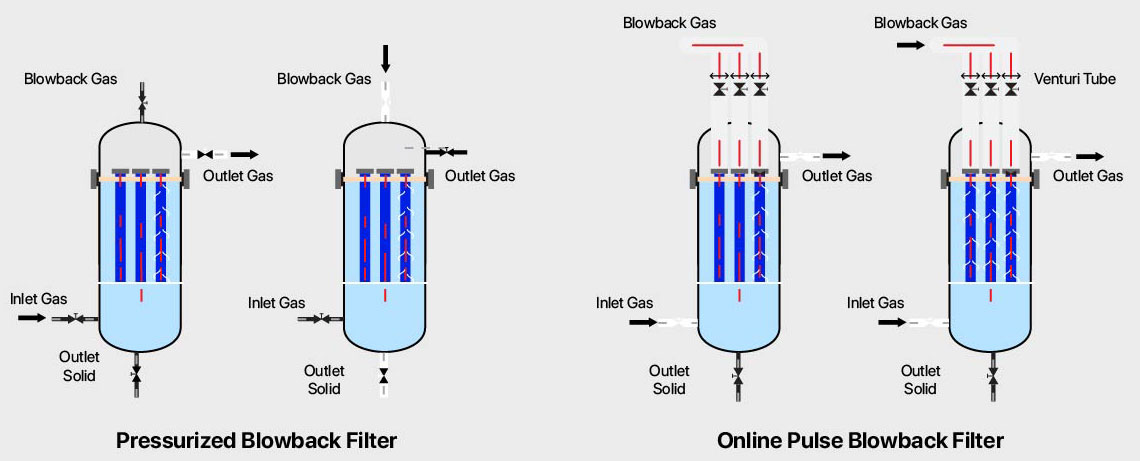

For hot gas filters, there are usually two backwashing cleaning methods: pressurized backwashing and online Venturi pulse backwashing. For pressurized backwashing, the filter must be isolated from the filtering process. With Venturi pulse backwashing, the filter can maintain a smooth flow without interrupting service.

Features and advantages of hot gas filters

- Easy to clean. The difference from ordinary bag filters is that forced cooling of the gas is unnecessary in the early stages. It solves the problems of other industrial filter elements that are easy to deform due to high temperature or high temperature resistance, poor back-blowing regeneration performance, poor filtering capacity and efficiency, and filter adhesion that is difficult to discharge.

- Small thermal deformation. Therefore, the high-temperature jet dust collector is the best choice for high-temperature flue gas purification. No bending deformation at high temperature can ensure the stable operation of the dust removal system.

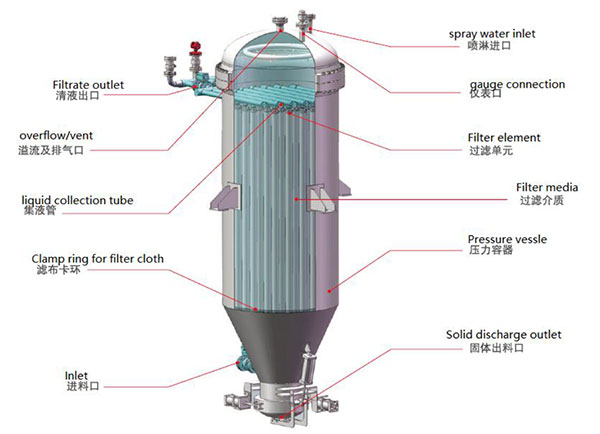

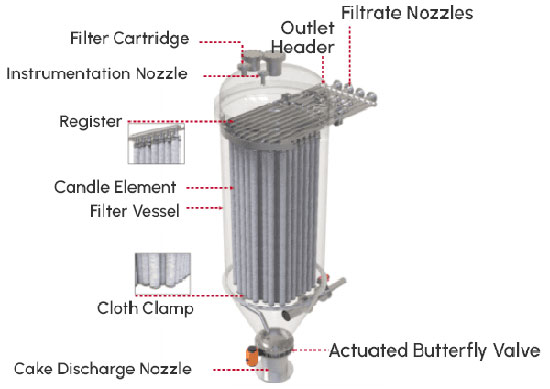

- Compact and space-saving design. Excelfilter industrial gas filters (clusters) are installed vertically in the filter housing. This allows a compact and space-saving design and greatly simplifies installation.

High-temperature gas filtration is easy to install, maintain and operate, and is an efficient and economical dust recovery solution. These exhaust ports of high-temperature gas filters can filter continuously for a long time. Permanent temperature resistance up to 450°C

The housing material is made of S304 and a variety of optional alloys. The unit structure is very strong and can withstand heavy loads, supporting the flexibility of your application needs. The specifications and dimensions of the high-temperature gas filtration system can be customized according to the relevant data you support.

Hot gas filtration process

Efficient and economical

Excelfilter high temperature gas filters have super mature technologies such as online pulse backwashing and chamber backwashing, which are particularly suitable for high temperature industrial applications. Depending on the dust and filter media, the clean gas that can be obtained by our hot gas filters is significantly lower than 5mg/Nm.

The optimal design of the filtration system requires the correct selection of the surface velocity to achieve long-term online operation and prevent particles from invading the media. Filter designs that exceed the maximum surface velocity will cause premature clogging of the filter element.

Gas filtration performance is enhanced when a surface or filter cake that provides additional long-term filtration is formed. The optimal surface velocity is usually in the range of 6-8 feet/minute (3-4 cm/second) to ensure that the filter cake is fully removed during the pulse backwashing cleaning cycle.

The internal filter element of the hot gas filter can be selected according to your specific application. The optional standard filter elements are sintered hot gas metal powder filter element, standard hot gas cleaning filter, hot gas sintered metal felt filter, and enhanced hot gas cleaning filter. It is made of a special sintered metal process and has excellent wear resistance and high temperature resistance. Combined with pulse technology, it can work continuously for a long time and reduce downtime.

Generally, the service life of the filter element can reach 3 to 5 years, which is 4 to 6 times the service life of the bag filter. The standard model can be used in the most severe conditions, but if you need different materials, we will be happy to work with you to meet your needs.

High temperature gas filter application

- Recover the heat energy of exhaust gas and improve the overall efficiency.

- Separation of gas components by combining adsorption and catalytic processes.

- Separation of combustible dust

- Waste incineration – hospital and chemical industry

- Coal gasification

- High temperature decomposition

- Calciners and kilns

- Product recovery in process technology

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.