Horizontal Self Cleaning Filter

The horizontal filters feature a unique automatic self-cleaning water filter configuration. Horizontal self cleaning filters can be installed in any orientation. The self-cleaning water filter has a parallel flange configuration for easy installation, can be integrated with any straight tube.

The industrial water filters are characterized by a two-stage screening. Each water filtration system consists of a coarse screen and a fine screen. The coarse screen is responsible for filtering out large debris from the water source, and the fine screen purifies the water to the specified requirements. These automatic water filters provide solutions for a variety of industrial, irrigation and municipal applications.

Screen Options

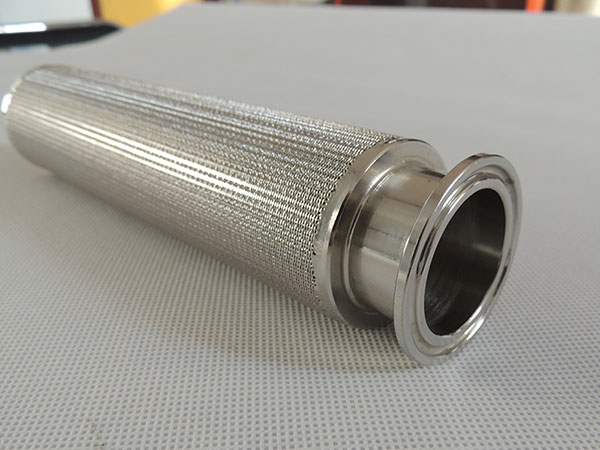

Sintered Mesh on Perforated Metal Plate

- Degree of Filtration Options (Micron): 5, 10, 25, 50, 75, 100, 120, 150, 200, 300, 500, 1000, 2000.

- Material: Standard 316L stainless. Screen is fused to stainless steel perforated plate for maximum durability.

- Particle Removal: 98-100% particle removal efficiency above the degree of filtration.

- Flow Capacity: Maximize flow per square inch of screen area with sintered mesh.

Wedge Wire

- Degree of Filtration Options (Micron): 25, 50, 75, 100, 120, 150, 200, 300, 500, 1000, 2000.

- Material: Standard 316L stainless.

- Particle Removal: 98-100% particle removal efficiency above the degree of filtration. Great for removal of fibrous material including pulp and paper fibers, fibrous algae, fruit fiber in juice processing, etc.

- Bursting Pressure: Robust construction ideal for high pressure environments.

Install Notice

- One check valve must be installed at filter outlet. Return pressure and back water is forbidden, in case of screen out of shape.

- If system wok pressure over 0.8MPa, should install break valve at drain pipe to reduce impact to screen.

- Notice motor rotating direction. Shut off power immediately once back rotating (anti-clock wise ).

- Installation each part according to arrow direction.

- Sudden pressure relief at outlet pipe is forbidden. Take normal work pressure 1.3MPa for example, if suddenly open branch valve at outlet, it will occur instant huge different pressure, which damage screen.

- Make sure filter used under correct work pressure, capacity.

- If alarms, open by-passvalve for temporary back washing solutions.

- Make sure control box have constant power supplv. If power off, users can open by-pass valve, close in and outlet valve and control box switch.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.