High Temperature Dust Collector

High-temperature dust removal filtration system using high-temperature flue gas waste heat recovery and high-temperature gas purification is an important measure for energy saving and environmental protection. In view of its characteristics and governance problems, our company specializes in high-temperature smoke and dust management of industrial furnaces and kilns, and has developed a high temperature dust collector as the core technology of high efficiency high-temperature dust removal filter. No need for forced cooling, direct purification and dust removal.

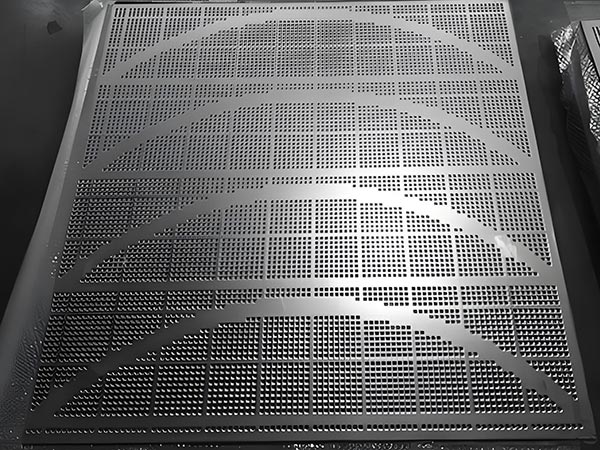

The dust filter cartridge is made of stainless steel fiber sintered felt, iron aluminum fiber sintered felt and stainless steel sintered mesh. It is a good solution to the problem that other filter materials are easy to “burn” at low and high temperatures. After cooling the temperature is too low, other substances precipitation and paste bag bad, backwashing performance is not good, poor filtration capacity and efficiency, filter media adhesion, unloading difficulties and other issues. Including filtration problems under high temperature conditions, anti-static buildup explosion-proof conditions. In recent years, metallurgy, chemical industry, building materials and other industries have built a number of furnace and kiln dust control projects.

Operating Principle of High Temperature Dust Collector

- Continuous duty dust collector

- Filters are cleaned online during continuous operation

- During normal operation dust laden air enters the unit through the air & dust inlet.

- The velocity is reduced when dust particles enter and natural per separation is caused by gravity. Heavier particles will fall directly into the collection tank through hopper and fine particles will accumulate on the outer surface of the filter bags. The clean filtered air passes through the clean air outlet.

- The fine dust particles that are accumulated in the outer surface of the filter bags are cleaned by the reverse pulse jet cleaning system using compressed air at regular time intervals, this dust will be collected in the collection tank.

- Sometimes used Dust collection System as a material I product recovery.

Scope of application of high temperature dust removal filter

Used for filtration of high temperature gases and other media, widely used in steel mills, power plants, cement plants, natural gas and other industries, it is an ideal substitute for other dust removal materials.

High Temperature Baghouse Design

High temperature baghouse filters are treated with insulating materials and special coatings. They can be equipped with a variety of accessories such as explosion-proof doors, spark suppression systems and broken bag detectors. In addition, baghouse MCCs, cleaning systems and access doors are customized to meet the specific needs of each application for more efficient and effective operation.

High temperature dust collectors are designed for continuous operation at temperatures ranging from 275 to 500 degrees Fahrenheit (135 to 360 degrees Celsius). This temperature range ensures that the filters are durable enough to withstand the highest temperatures while still providing a high level of filtration. They are typically made of aramid fiber, fiberglass, or PTFE membranes, which are highly resistant to temperature fluctuations. The filtration materials used are designed to capture particles of different sizes, ranging from 0.5 microns to 10 microns in size. This eliminates dust and other contaminants from the air while allowing air to pass through the filter.

High-temperature dust collectors are among the most reliable and effective filtration devices because they are able to withstand the most demanding industrial processes. As such, they are the perfect solution for many different types of industrial applications.

Practical advantages of high temperature dust collector

- High temperature resistance

- Durable

- High filtration precision

- Good chemical corrosion resistance

- Good regenerability

- Suitable for heavy dust

- Easy to use & installation

- Easy maintenance

- Compact design

- No compressed air requirement for filter cleaning

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.