Hastelloy Nickel Based Alloy Sintered Wire Mesh

Hastelloy alloys primarily used for sintered wire mesh are the Hastelloy C series. This is a nickel-molybdenum-chromium alloy with tungsten additions that provides excellent corrosion resistance in a variety of harsh environments including hypochlorite, wet chlorine gas, and chlorine dioxide solutions. Hastelloy C-276 (UNS N10276) is particularly resistant to pitting and crevice corrosion, even in sulphuric acid, acetic acid, phosphoric acid, and nitric acid environments. Hastelloy C-276 also has good resistance to grain boundary carbide precipitation formation Welding.

| Hastelloy | EN w.nr. | Ni | Fe | Cr | C | Mo | Other |

| C276 | 2.4819 | Balance | 4.0-7.0 | 14.0-16.0 | <0.02 | 15.0-17.0 | W 3.0-4.5 |

| C22 | 2.4602 | Balance | 2.0-6.0 | 20.0-22.5 | <0.02 | 12.0-14.5 | W 2.0-3.5 |

C-22 (UNS N06022) has better overall corrosion resistance at elevated temperatures and even better resistance to pitting corrosion.

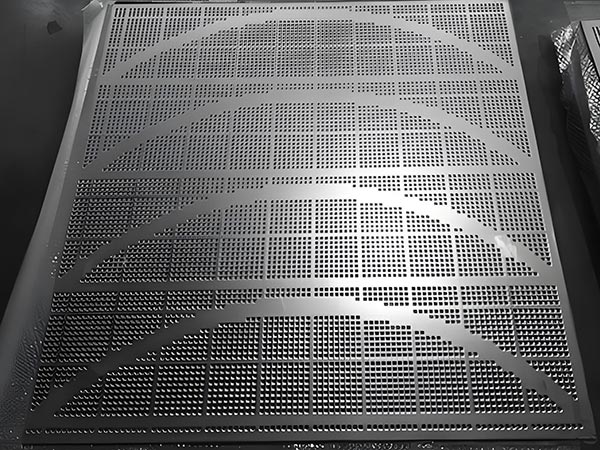

hastelloy sintered wire mesh with dead zone peforated metal

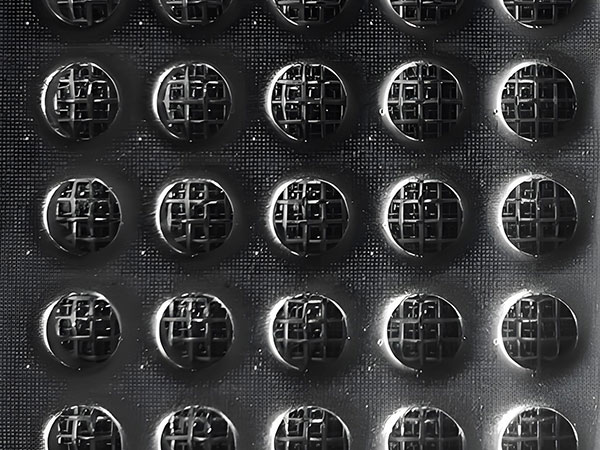

hastelloy sintered wire mesh with round hole peforated metal

Hastelloy C is highly resistant to oxidising chloride salt solutions (including iron and copper ions). It also performs well in seawater, especially in crevice conditions where other commonly used alloys fail, such as 316L 904L stainless steel, Monel 400, and Inconel 625.

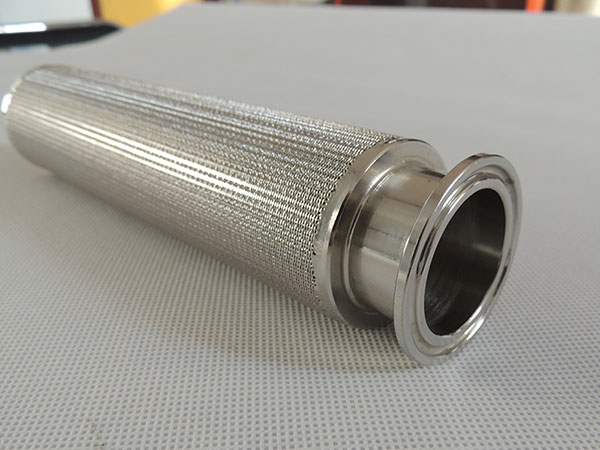

Hastelloy C-276 and C-22 sintered wire mesh has a micron rating range of 5-200 microns. Hastelloy perforated metals are also available, so sintered wire screens with perforated metals can be made from all-Hastelloy materials.

Applications for Hastelloy Sintered Wire Mesh

Major applications for Hastelloy Nickel Based Alloy Sintered Wire Mesh include:

- Chemical Processing

- Pharmaceutical Production

- Pulp and Paper Bleaching

- Oil and Gas Production

- Petrochemical Processes

- Fuel Gas Desulphurisation

- Seawater Related Filtration

Hastelloy Nickel Based Alloy Sintered Wire Mesh Manufacturer in China

Excellent Filters is one of the best choices for Hastelloy C276 C22 sintered wire mesh and corresponding filtration elements worldwide. For many years, we have supplied Hastelloy sintered wire mesh and filtration elements to the chemical processing, pharmaceutical, and other industries dealing with severely corrosive media.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.