Filter Plate

The chamber filter plate is composed of a filter plate and a filter frame, where two compacted filter plates form a separate chamber and the filter cake is formed as a layer on the filter plate. As the cake thickness increases, permeability and flow rates decrease, resulting in longer filter cycles and higher operating costs.

Later in the filtration cycle, higher feed pressures are used to dry the cake and this dewatering phase is quite long. This phase is often referred to as the non-productive phase.

Chamber plates used alone are suitable for general purpose applications where the requirements for cake dewatering are not high. Instead, the use of a combination of chamber and membrane plates will effectively shorten the filtration cycle and save operating costs.

Welded Membrane Filter Plate

Welded membrane filter plate is the top priority when selecting a filter plate, for it significantly shortens the filter cycle by skipping the non-productive phase of pressure filtration. A couple of welded membrane plates can be used alone or combined with chamber plate. The combination makes full use of each other’s advantages. Chamber filter plate is quite effective in the first part of filtration, and during the non-production part, membrane plate will significantly shorten the operation time and reduce the dryness of the cake.

Welded membrane plate is an integral whole, and replaceable membrane plate can be separated into core body and membrane. Due to this character, the whole membrane plate should be replaced whether core body plate or membrane has damaged. This will increase production cost.

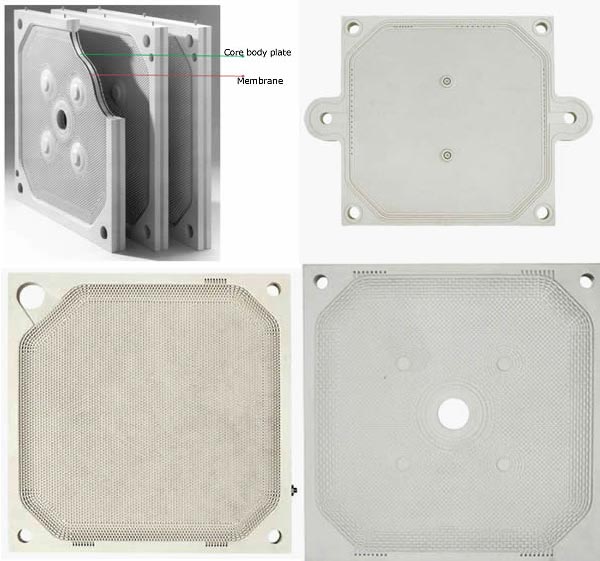

Replaceable Membrane Filter Plate

Replaceable membrane filter plate can be roughly separated into three parts – core plate and two membranes. This special construction gives its capability of replaceable membrane apart from the main advantages of welded membrane filter plate. Once the membrane has been damaged due to aging or external forces, just replace the membrane without using a new membrane plate. What is more, the membrane replacement can occur in the filter press.

Note: Replaceable membrane plates must be cooperated with chamber filter plate.

Materials: Various materials are used, such as polypropylene, thermoplastic elastomer (TPE), synthetic rubbers such as EPDM, NBR, and PVDF. The individual part of replaceable membrane filter plate can be made of different materials to meet with diverse applications.

Ceramic Filter Plate

Ceramic filter plate is an alternative method of solid and liquid separation. Porous ceramic filter tends to replace conventional filter plates for its extremely high working temperature, chemical inertness and excellent resistant to almost types of slurry.

Ceramic filter is used to remove solid particulate from liquid and gas in chemical process, petrochemical, food and beverage, pharmaceutical industries, paper making and ore concentrate dewatering of copper, lead, zinc, iron, silver, sulfur, gold for its unique porous structure.

Materials: Aluminum oxide is the most popular raw material of ceramic plate. its maximum operation temperature can reach 1400 °F.

Silicon carbide is the premier choice for harsh applications, for its maximum working temperature can be as high as 1800 °F.

Characteristics of filter plate

Conical points in the recessed area not only support the filter cloth, but also provide a drainage path for the filtrate.

A variety of feeding methods to meet different applications, such as center feeding, head feeding, foot feeding, corner feeding, external feeding, etc. Other special feeding methods can also be customized according to actual needs.

High-pressure filtration reduces the water content of the cake considerably.

Maximum filter pressure is 7 bar (101 psi) or 16 bar (232 psi).

Maximum operating temperature is 120°C.

Filter Plate Construction

The chamber recessed filter plate is a solid plate. It typically consists of feed holes, filter zones, drain holes, sealing edges, and hard points. The number of hard points depends on the thickness of the plate. The feed position is not fixed. There are five types of feed locations – center, corner, outside, head and foot. When the plate is under pressure, the sealing edges are machined parallel to the seal.

Filter Plate Materials

Polypropylene (PP) is a common raw material for filter plates, which is chemically inert, resistant to oxidation, corrosion, and high temperatures, lightweight, and strong.

In addition, ultra-high molecular weight polyethylene (UHMWPE) and toughened rubber are particularly suitable for harsher environments due to their long service life, good abrasion resistance, chemical stability and high compressive strength.

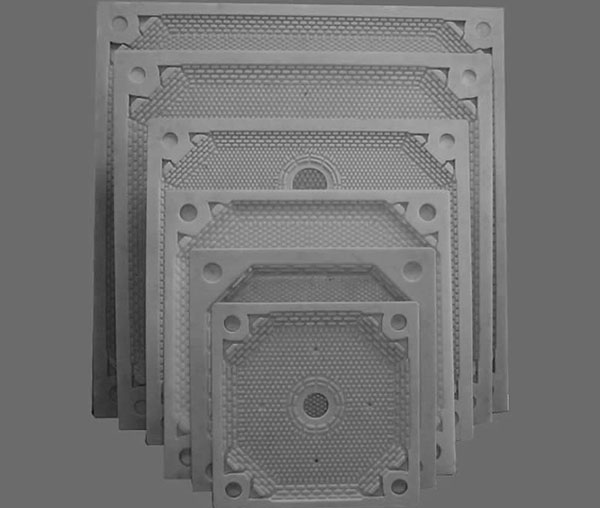

Size and Shape

Standard sizes: 250, 400, 470, 500, 630, 800, 915, 1000, 1067, 1200, 1300, 1450, 1470, 1500 1500 × 2000 and 2000 × 2000 mm.

Standard shapes: square, rectangular and round.

Larger sizes or different shapes can be customized for special orders.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.