Fiber Bed Mist Eliminator

Excelfilter fiber bed mist eliminator is called Fiber Bed Filter or candle filter mist eliminator. Its unique Filter Element design enhances its ability to capture fine particles. It is the best Fiber Bed Filter to remove 1-3 micron liquid aerosols in gases and gas streams, with a collection and removal efficiency of up to 99.9%.

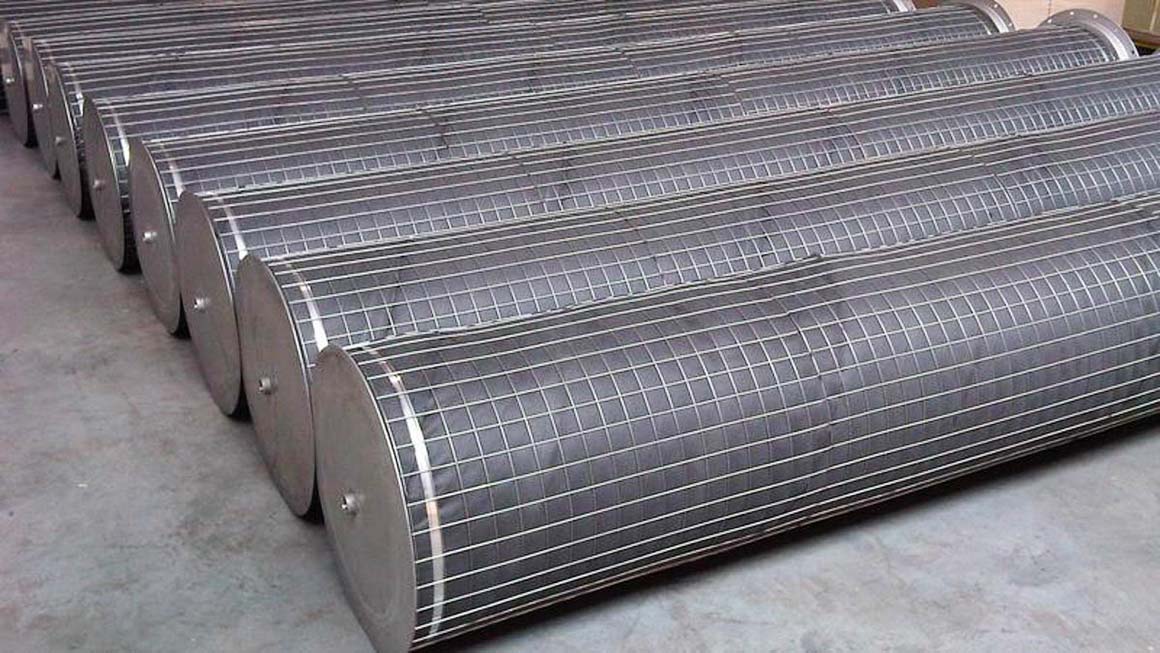

They are usually cylindrical elements. Gas streams and process gases eliminate contamination or hazard issues, collecting valuable materials even with heavy liquid loads. Excelfilter’s mist removal technology is widely used in emission reduction facilities in various industries.

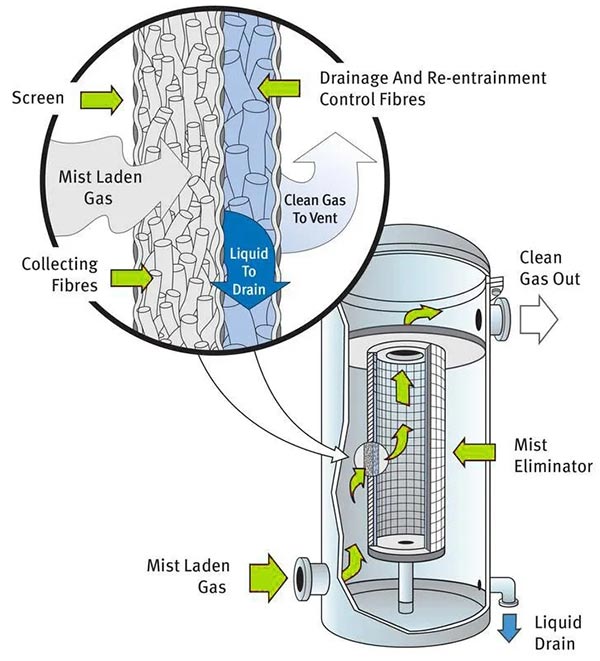

Candle filter mist eliminator construction

Excelfilter Candle Filter Mist Eliminator is composed of compressed glass fiber wool filled between two concentric cage meshes, or parallel flat screen meshes with a height of 610mm to 6100mm. Depending on the process environment, Excelfilter Fiber Bed Candle Filters can provide customers with personalized design and manufacturing. Their inner and outer screens (or cages) are made of alloys, thermoformed plastics, or glass fiber-reinforced plastics. The materials used in the compressed fiber bed are unique glass fiber cotton containing fluoro silicone oil, polypropylene, polytetrafluoroethylene, or polyester fiber. Structural screen/cage components and flanges can also be made from any weldable metal, plastic, or glass-reinforced resin.

The cylinder cage mesh comprises two kinds of screens divided into the outer and inner screens. The Fiber Glass Mist Eliminator material forms a fiber bed between the inner and outer cylindrical screens. The operating parameters of Excelfilter fiber bed mist eliminators, such as pressure drop, collection efficiency, and gas flow rate, depend on the fiber diameter, fiber material, and packing density. Plates and flanges are attached to the ends to support multiple installation and drainage methods.

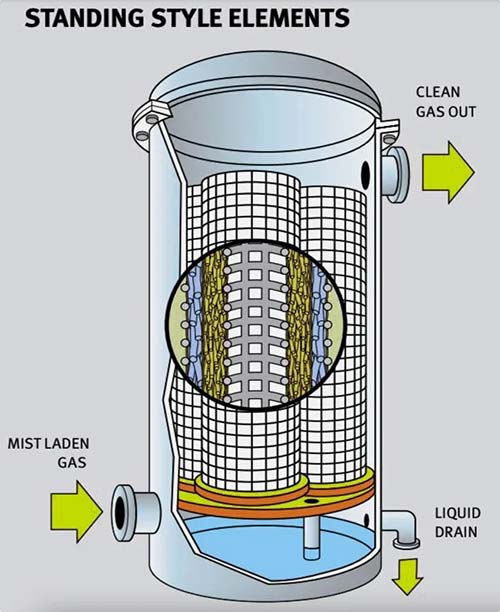

Candle filter mist eliminator processes

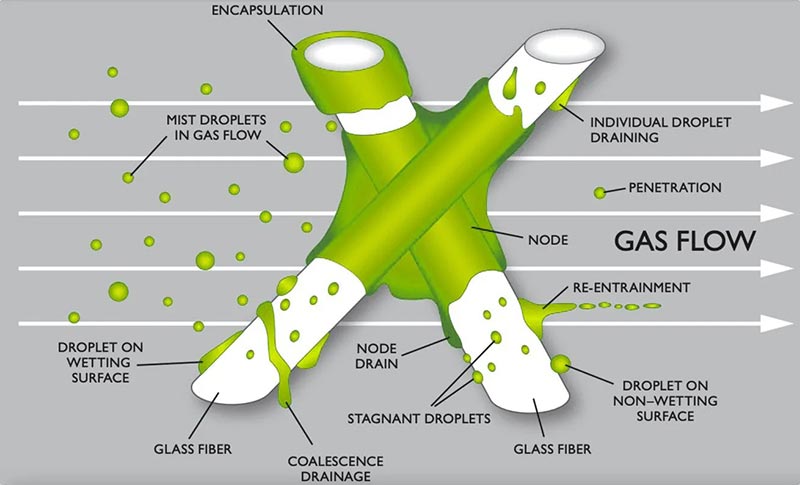

All fiber bed mist eliminators’ mist collection methods are similar. The gas containing mist droplets is guided horizontally through the fiber bed, and the mist droplets accumulate on each fiber in the fiber bed and gradually form a liquid film. These liquid films are then passed through the fiber bed by airflow, and the clean gas is discharged from the other side. Gravity removes The liquid from the downstream side of the fiber bed. Typically, Excelfilter fiber bed mist eliminators are installed in containers or tanks whose bottoms allow continuous drainage of the collected liquid.

When particles try to pass through fiber bed mist eliminators, the fibers capture and retain them. In comparison, larger particles are collected by inertial impaction or fiber interception methods. Fiber Glass Mist Eliminator’s high-efficiency results from Brownian gas motion and the influence of gas molecules on the smallest submicron particles. This collection mechanism is called Brownian diffusion. Over time, the collected liquid particles (or dissolved soluble solids) aggregate into droplets on the Fiber Glass Mist Eliminator’s fiber surface and are then expelled by gravity.

Fiber bed filter the difference between low-speed type and high-speed type

Low-speed Fiber Bed Filters are high-efficiency Fiber Bed Candles Filters based on Brownian diffusion and collection. They are characterized by low airspeed, between 0.08 and 0.2m/s, and are used to capture mist particles that are less than 1 micron on average. , the collection efficiency is between 94% and 99.7%; for mist particles larger than 3 microns, the collection efficiency is 100%.

This candle filter mist eliminator form has a thick, tight fiber bed, thin fibers, and resistance between 490 ~1960 Pa. The size of the opposition is related to the fiber-filling density of the candle filter mist eliminator, the selected airspeed, and the defogging efficiency required by the user. The number of defogging elements must be increased if the user needs higher defogging efficiency and lower resistance.

The high-speed fiber bed filter is a Excelfilter fiber bed mist eliminator that captures mist particles by inertial collision and interception. It is characterized by high air speed, between 2.0 and 2.5m/s, and charges 1 to 3 microns of mist. For particles, the collection efficiency is about 97%, and the resistance is between 1470~2450Pa.

Standard fibre bed mist eliminator specification sheet

| Model | Size (mm) | Technical Performance | ||||||

|---|---|---|---|---|---|---|---|---|

| OD | ID | H | Flow(m3/h) | Pressure Loss Range(mm/H2O) | Operate Temperature(℃) | Velocity Range(m/s) | Efficiency (%) | |

| CWQ-M | 470 | 400 | 2000 | 1000-1200 | 60-150 | <70 | 0.14-0.25 | Particle Size >3μm 98% |

| 470 | 400 | 2500 | 1200-1500 | |||||

| 470 | 400 | 3000 | 1500-1800 | |||||

| CWQ-A-R | 460 | 350 | 2000 | 1000-1200 | 60-200 | <85 | 0.14-0.25 | Particle Size >3μm 100% |

| 460 | 350 | 2500 | 1200-1500 | |||||

| 460 | 350 | 3000 | 1500-1800 | |||||

| CWQ-M-R | 470 | 360 | 2000 | 1000-1200 | 60-200 | <85 | 0.14-0.25 | Particle Size >3μm 100% |

| 470 | 360 | 2500 | 1200-1500 | |||||

| 470 | 360 | 3000 | 1500-1800 | |||||

| CWQ-M-R | 470 | 360 | 2000 | 1000-1200 | 60-200 | <70 | 0.14-0.25 | Particle Size >3μm 100% |

| 470 | 360 | 2500 | 1200-1500 | |||||

| 470 | 360 | 3000 | 1500-1800 | |||||

| CWQ-R | 480 | 350 | 2000 | 1000-2200 | 60-200 | <85 | 0.14-0.25 | Particle Size >3μm 100% |

| 480 | 350 | 2500 | 1200-2500 | |||||

| 480 | 350 | 3000 | 1500-2800 | |||||

| CWQ-R* | 480 | 380 | 2500 | 1200-1500 | 80-300 | <85 | 0.14-0.25 | Particle Size >3μm 100% |

| 480 | 380 | 3000 | 1500-1800 | 1-3μm 90%-95% | ||||

| 480 | 380 | 3500 | 1800-2400 | 0.75-1μm 70-90% | ||||

| 480 | 380 | 4000 | 2400-2800 | |||||

| CWQ-R | 607 | 508 | 4000 | 8000 | 50-200 | <85 | 0.16-0.25 | Particle Size >3μm 100% |

| CQ-R* | 570 | 470 | 3500 | 3000 | 100-300 | <85 | 0.14-0.25 | Particle Size>3μm 100% |

| CW-R* | 607 | 508 | 3600 | 3500 | 100-350 | <85 | 0.1-0.35 | Particle Size>3μm 100% |

| Particle Size<3μm 99% | ||||||||

| CW-R | 607 | 508 | 1000-2000 | 2000-8000 | 50-350 | <85 | 0.1-2.5 | Particle Size>3μm 100% |

| CW-R | 620 | 508 | 1000-2000 | 3000-10000 | 50-380 | <85 | 0.1-2.5 | Particle Size>3μm 100% |

| R * is an efficient candle filter mist eliminator, and the Pressure Loss Range can be adjusted according to user requirements. Special custom size diameter from (216 mm to 610+mm), lengths up to (7315 mm) | ||||||||

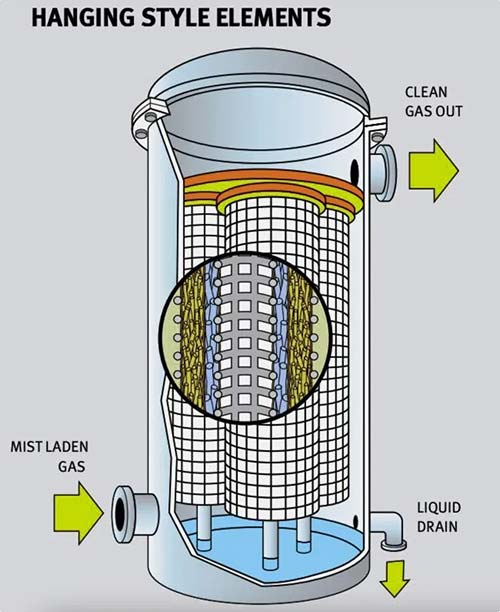

Excelfilter fiber bed mist eliminator installation type

Hanging-style fiber bed mist eliminator – Also known as Forward Flow, hangs from a tube sheet or vessel divider. This configuration is straightforward to install and maintain. In this design, contaminated gases enter the outside of the element, while clean gases exit the central core.

Standing-style fiber bed mist eliminator – Also known as Reverse Flow, mounted vertically on a tube sheet or vessel divider. This configuration allows the use of more extended elements and reduces the size of the container. In this design, contaminated gases enter the central core of the component, while clean gases exit from the outside.

Excelfilter fiber bed mist eliminator replacement

Excelfilter designs and manufactures Replacement Fiber Bed Candle Filter Elements for various processing applications to reduce and eliminate liquid mist and aerosol emissions. These systems are available using standard Fiber Mist Eliminator elements configurations or can be custom-designed to fit your specific installation. Fiber bed mist eliminators element solution designed specifically for existing equipment can replace waste filtration systems.

Existing fiber bed filters from any manufacturer can be replaced with Excelfilter’s fiber bed filters to improve performance and extend the life of the Fiber Bed Filter. Excelfilter’s sales and technical teams have extensive experience working with existing installations, which enables them to provide you with the exact solution. All fiber bed filters are manufactured in our factory to the highest quality control and manufacturing standards. After assembly, each fiber bed mist eliminator element must be individually tested for pressure drop, aerosol removal efficiency, and flow distribution.

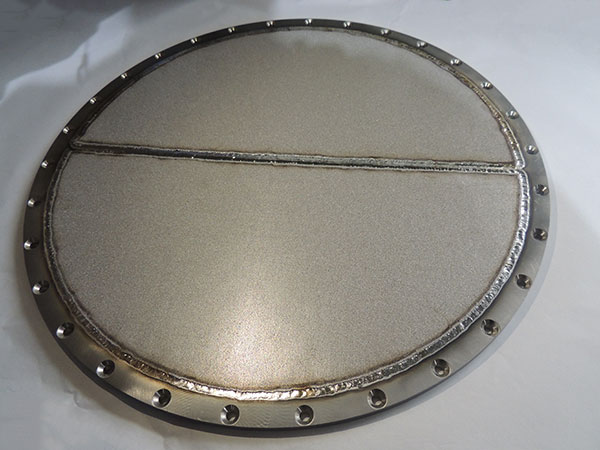

Detail display of candle filter mist eliminator

Not only in fiber components, we strive for excellence, but also in other components, we strive for perfection. All metal components are made of anti-corrosion materials such as 316L, and sealing washers are made of specially made VITON materials. Maximizing the service life of the fiber defoamer.

Features of fiber bed mist eliminator

- Low total operating cost of ownership

- Custom-designed filters for new or existing systems

- Simplify maintenance

- Available in standard and custom design configurations

- Filter life up to 10 years

- High-quality control and fast delivery

- Helps eliminate visible chimney plumes

- Meet today’s stricter air pollution regulations

Benefits of fiber bed mist eliminator

- Air Pollution Control: Removal of small and submicron particles with the most significant tendency to cause opacity and plume persistence in stack gases. Excelfilter mist eliminator systems effectively remove these particles, eliminating visible and harmful air pollution.

- Reduced Maintenance: Remove harmful mists that can cause downstream corrosion, plugging, or fouling.

- Longer Service Life: Mist eliminators offer superior service life. Whether for sulfuric acid plants, chlorine plants, engineered package systems, or other industrial processes, mist eliminators have a solid history of robust and sturdy mechanical construction, whatever the service environment.

- Improved Product Purity: Removal of contaminating mists and soluble solids at collection efficiencies of nearly 100 percent. The particle size gets smaller (below three microns and in the sub-micron ranges).

- Reduced Material Loss: Reduced material losses can partially offset or even completely pay for the system.

- Safer Operation: Removal of dangerous mists that create potential fires or explosions in process gas streams and compressed air systems.

- Improved Process Design and Operation: Removal of submicron mists in a process gas stream can eliminate the need for more costly construction materials for downstream equipment and permit more efficient operating conditions that increase product yield.

Applications of fiber bed mist eliminator

- Mist eliminator process application

- Gas-liquid separator

- Distillation equipment

- Process absorbers, settlers, and scrubbers

- Chemical separators and extractors

- Oil and Gas Processing Equipment Gas

- Scrubber gas-liquid separator and receiver

- Refining tower liquid

- Liquid coalescer

- Pollution control equipment

- Two-phase eliminator compressor

- Liquid entrainment of equipment

- Product return system

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.