Ballast Water Filter

The ballast water filter for automatic pre-filtration of sea water, presents an inexpensive top technology for new construction, retrofitting as well as solid protection for ballast-water treatment systems.

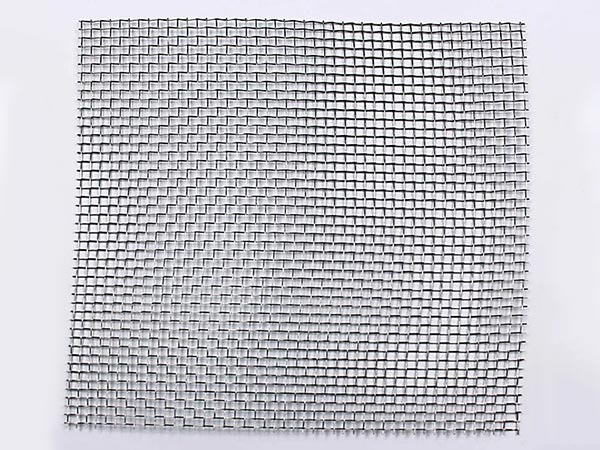

For the ballast water management system on large vessels, there are numerous solutions available. To protect these multi-stage ballast water treatment systems, the majority of the systems require automatic pre-filtration of the sea water taken on board. Therefore, a fine filter is installed between a coarse separator and the chemical or physical disinfection units. The ballast water filter task is to remove living organisms, as well as sediment from the water.

Ballast water treatment system is a system designed to remove and destroy/inactive biological organisms (zooplankton, algae, bacteria) from ballast water. Ballast water treatment is still evolving technology with an ever-growing number of manufacturers. This means that there is limited inservice experience for the systems being offered and there is a general understanding that no single system is suitable for all ship types.

Most ballast water treatment systems use a two-stage approach, involving a form of mechanical separation followed by physical or chemical treatment. The two most common technologies are ultra-violet based systems and electro-chlorination systems. Ultra-violet systems use physical ultra-violet radiation as secondary treatment, where electro-chlorination makes use of a chemical ‘active substance’ to inactivate biological organisms. Both systems typically employ filtration as mechanical first phase treatment.

Features of ballast water filter

- Have precise degree of separation.

- Eliminate blockages of the filter mesh, despite high load of the ballast water.

- Be easy to install, retrofit, operate and maintain.

- Combine the required filtration efficiency with high flow rates and Long intervals between back flush cycles.

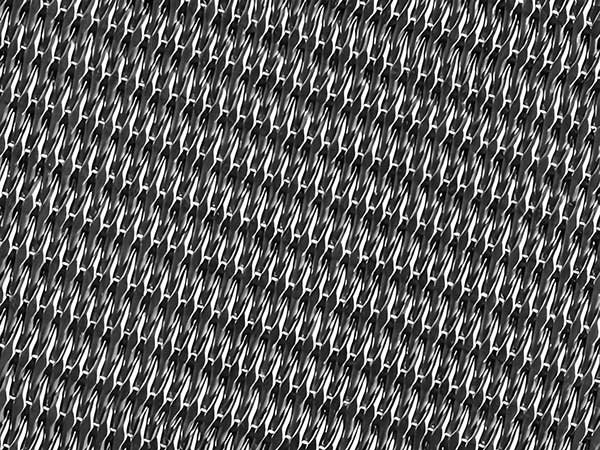

- Filter material needs to be seawater resistant.

- Have a low footprint and keeping the operating costs of the system as low as possible.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.