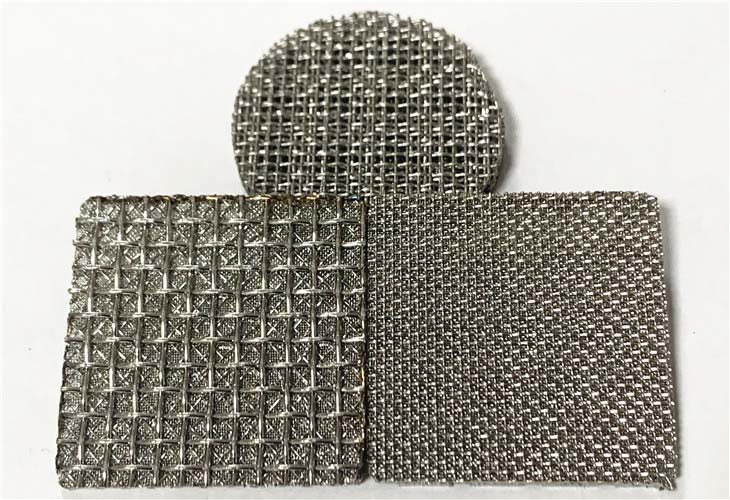

All Square Weave Sintered Wire Mesh

All square weave sintered wire mesh is type B, where all the wire mesh layers are square woven. Square woven mesh has square openings and a high porosity. Due to these characteristics, type B sintered wire mesh has excellent permeability and is more suitable for applications with high flow rates.

Typical applications may include: sand control tubes, Y-type filter tubes, automatic filter screens, etc.

Several structures and layer configurations are listed here, and many other combinations can also be customized according to customer specific needs.

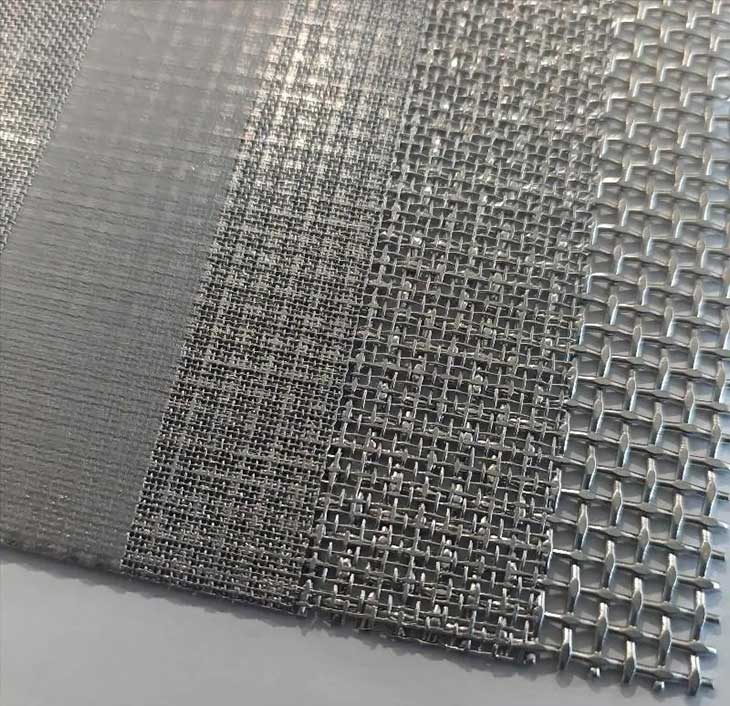

Sintered mesh for flame arresters or noise attenuation

Another application of all square woven sintered wire mesh is to sinter many layers of square woven mesh to form a very thick plate for flame and explosion arresters or noise attenuation. This sintered mesh laminate plate can be several centimeters thick and still have high flow characteristics.

Material selection for all square woven sintered wire mesh

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are standard materials for type B full square woven sintered wire mesh.

Other exotic materials are also available upon request such as 310S, 904L, Hastelloy C276, Hastelloy C22, Monel 400, Inconel 625, etc.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.