All Dutch Weave Sintered Wire Mesh

D-type sintered wire mesh is made of two or three layers of Dutch plain woven wire cloth sintered together. The arrangement of these layers is carefully designed to obtain a uniform pore distribution. D-type is widely used in applications such as ventilation, injection, fluidization, powder handling, air drying, etc.

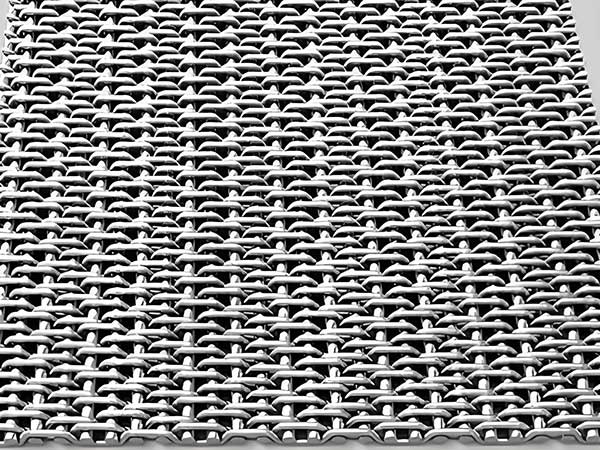

All Dutch weave sintered wire mesh – 2 layer

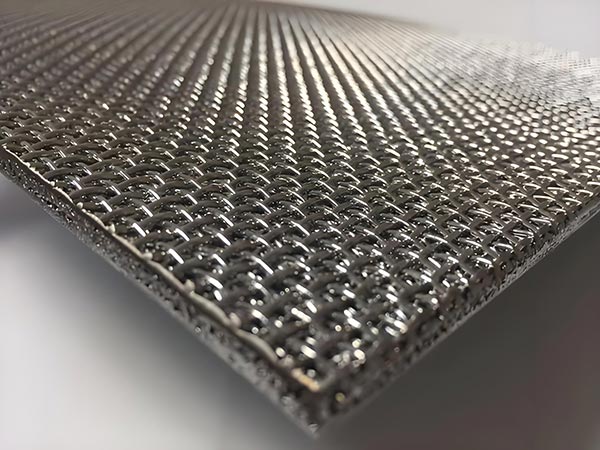

Side view of a sintered Dutch weave mesh filter tube

Material Selection for All Dutch Weave Sintered Wire Mesh

316 (1.4401), 316L (1.4404), 304, 304L stainless steel are the standard materials for D-type sintered wire mesh.

Other exotic materials are also available on request, such as 310S, 904L, Hastelloy C276, Hastelloy C22, Monel 400, Inconel 625, etc.

FAQ's

There are many ways to keep you going. Maintenance is crucial for industrial water filters to achieve sufficient filtration and long-term use. To avoid being shut down, you must clean and replace your filter element according to the manufacturer's instructions.

- Plan to regularly inspect the internal screen components.

- Arrange regular inspections of electronic control systems.

- Arrange to regularly add lubricating grease to bolts and sealing components.

- Regularly inspect the filter housing for paint peeling off..

Many industrial water filters need to be replaced within 18 months. Usually depends on the degree of pollution and frequency of use. Therefore, these factors will determine the service life of commercial water filters.