Is sintered metal wire mesh stronger?

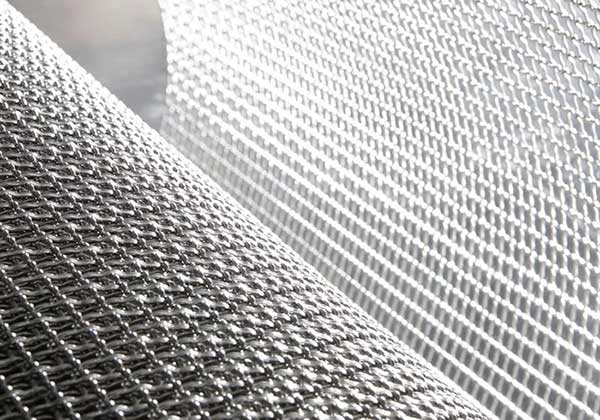

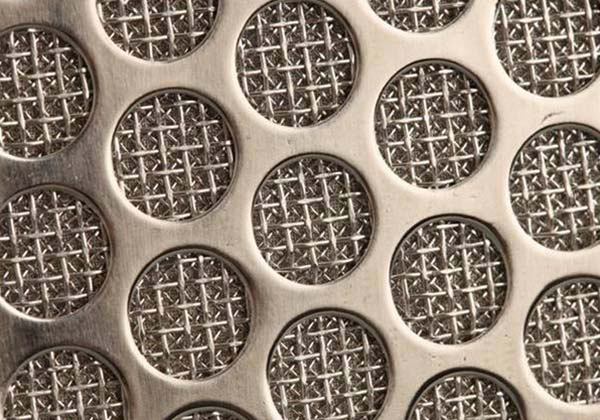

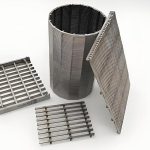

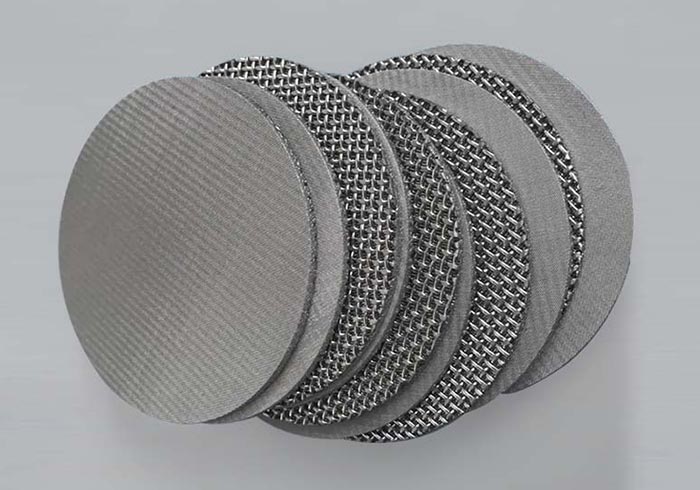

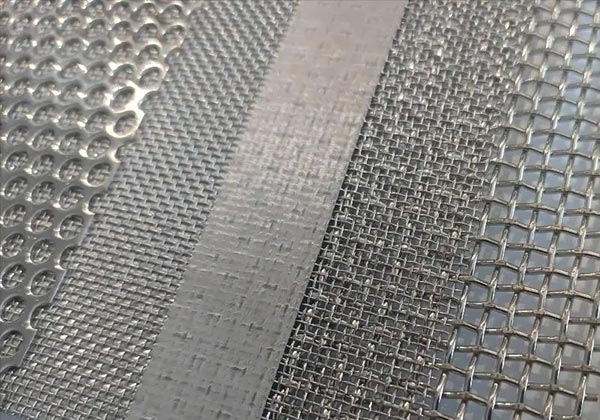

We offer various types of sintered mesh, such as 5-layer sintered mesh, ABCD type. Sintered metal wire mesh has significant advantages over non sintered metal wire mesh in many aspects. Due to its washability and reusability, it is more durable, efficient, and environmentally friendly. Woven metal wire mesh can be stacked in multiple layers and bonded together in a molecular manner through a sintering process, resulting in highly controlled and permeable materials suitable for manufacturing better filter discs and cutting blades.

Sintered quality sieve cloth makes it the best choice for mesh discs and other mesh filters that require fine filtration capacity and high mechanical strength. Sintered metal wire mesh is made by laminating woven metal wire mesh with different layers, and has several advantages compared to non sintered metal wire mesh.

Regular wire mesh can filter extremely fine particles as small as 1 micron, but the finest metal mesh is also very fragile, almost like a piece of paper. If a lot of pressure is applied during the filtration process, they are easily damaged or destroyed, just like a piece of paper is easily punctured. Using multiple layers of thicker and stronger woven mesh to sinter a fine mesh for support can preserve the fine filtering ability of the mesh while increasing the strength and compressive strength of the coarse mesh, which is integrated as a whole. The sintering heat treatment process also gives silk ductility, annealing ability, and formability. It increases tensile strength as well as thermal and electrical conductivity.