Bag filter dust collector maintenance and inspection checklist

In order to protect the health and safety of personnel in the surrounding environment, as well as ensure the normal and efficient operation of process equipment and machinery in the factory, the maintenance of bag filter dust collector is crucial. In other words, if your baghouse dust collector and ventilation system cannot achieve optimal performance levels, the equipment in the factory will have difficulty achieving productivity. By regularly cleaning and inspecting bag filters, potential problems can be identified and resolved to prevent their deterioration.

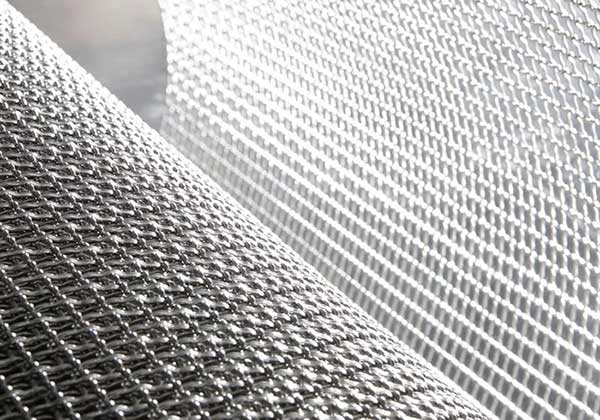

Improper operation of bag filter dust collector may lead to problems such as low filtration efficiency, filter material contamination, and airflow obstruction. All of these issues can be avoided through regular maintenance, including regular inspection of filter bags and replacement of filter cartridges. Regular maintenance can also help reduce the risk of fire caused by the accumulation of dust and other substances inside the baghouse dust collector.

In addition, regular maintenance of bag filters can help improve their overall efficiency. If the bag dust collector is maintained properly, the filter material will be able to capture higher concentrations of dust particles, which means lower energy consumption is required for system operation. This in turn reduces energy costs and helps improve the cost-effectiveness of bag filter systems.

Finally, maintenance of bag filter dust collector is crucial to ensure long-term operation of the system. Regular maintenance helps identify problems before they become serious, thereby reducing the likelihood of expensive repairs. This helps to keep the system running smoothly and efficiently, which can save costs in the long run.

In order to maximize the performance of baghouse dust collector, improve their efficiency, and achieve optimal service life for filter bags and other replaceable components, the following inspection and maintenance guidelines may be a useful tool.

Daily maintenance of bag filter dust collector

- Visually inspect the bag dust collector for any signs of abnormal operation.

- Check the chimney monitor (if applicable), or visually inspect for signs of dust.

- Check and record the pressure difference (3-4 inches of water column during normal operation).

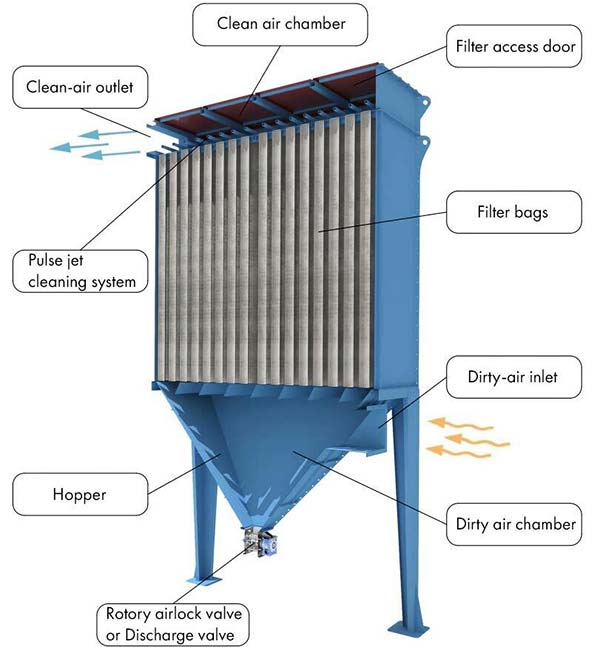

- Check if the hopper unloading device is properly dust removed.

Weekly maintenance of bag filter dust collector

- Visually inspect the bag for any tears or holes, and ensure that it is properly positioned.

- Check the cleaning sequence and ensure that all valves are correctly positioned.

- Check if the fan and fan drive components are worn.

- Check all hoses, connectors, and air pipelines of the baghouse dust collector.

- Monitor the emissions of bag filter to ensure sufficient removal of dust.

- Check all moving parts on the unloading system and screw conveyor bearings.

- Blow out the U-tube pressure gauge, Magnahelic or Photohelic pressure gauge pipeline.

- Listen to the cleaning cycle to ensure that all valves are functioning properly.

Monthly maintenance of bag filter dust collector

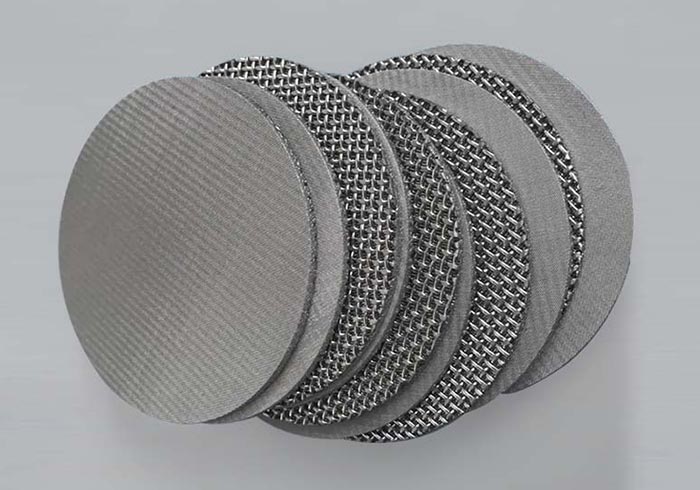

- Visually inspect the filter bag for any tears or holes, and ensure that it is installed correctly.

- Randomly check the tension of the reverse air bag and vibration bag.

- Check the compressed air pipeline filter.

- Check the operation, bypass, and isolation of the damper.

- Check the compressed air system, including filters and collectors.

- Check the timer board to ensure the correct cleaning sequence.

- Monitor the solenoid valve and pulse diaphragm valve to ensure proper ignition.

- Check all drive components on fans, exhaust valves, and screw conveyors.

- Check the fan for corrosion and blade wear.

- Spot check the installation of bags.

- Check all moving parts on the vibrating bag filter.

Quarterly maintenance of bag filter dust collector

- Check all door gaskets and seals.

- Confirm that the inlet temperature of the bag filter is correct.

- Thoroughly inspect all filter bags and filter cages.

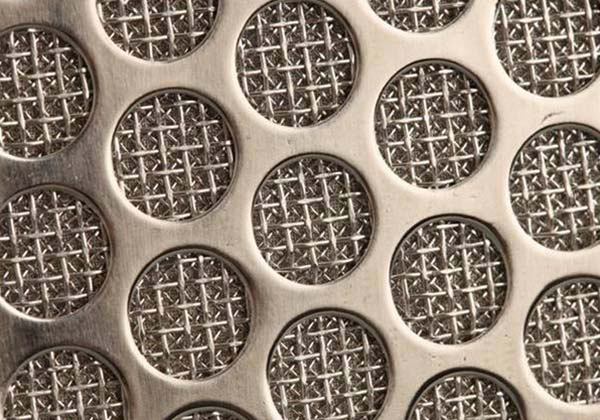

- Use leak detection testing to spot check for leaks and holes in bags.

- Check whether there is dust accumulation in the pipeline.

- Observe if the damping valve is properly seated (if applicable).

- Calibrate the opacity monitor (if necessary).

Annual maintenance of bag filter dust collector

- Check if the internal hopper is worn.

- Repair or replace high wear components of the cleaning system.

- Check all welds and bolts.

- Check if the structure of the baghouse dust collector is corroded.

- Check if the internal baffle (if applicable) is worn.

Other resources for maintaining baghouse dust collector

1. With the help of remote monitoring technology, the maintenance of bag filter dust collector can be easier, faster, and safer.

2. Fluorescent leak detection powder is one of the simplest and most economical methods to check whether the filter bag of a baghouse dust collector has holes, tears, or improper installation. It can also help you detect air leaks around the door caused by improper sealing, cracks in the pipe plate, or holes in the metal casing of the bag filter.

3. Know when to seek the help of a bag dust collector maintenance expert. Our bag filter maintenance team is happy to handle any bag filter and ventilation system related projects that your maintenance personnel need, including replacing bag filter bags.

4. To gain professional knowledge in daily operations, please provide training on factory bag filter dust collector and ventilation systems for your maintenance personnel. The maintenance workshop for Excelfilter’s bag dust collector and ventilation system can be conducted on-site or online, and English or Spanish versions are available. When on-site, our well-trained engineers and maintenance experts will arrive at your factory in advance and customize training courses based on the type of bag filter and related equipment in your factory, so that your employees can immediately apply the knowledge learned to operational improvement.