Industrial Water Filtration Systems

For industrial production, no matter what water is used in the process, filtration is essential to ensure efficient operation. Adequate filtration ensures product quality, energy and water efficiency, and sustainability. Excellent Industrial Water Filter Manufacturer can design, manufacture, and install custom Industrial Water Filtration Systems for various industrial water uses, such as Raw Water Supply, Cooling Water, Boiler Feed Water, Water For Process, Reclaimed Water, Cip And Sip, Wastewater Treatment, And Disposal.

Excellent provides a series of advanced water treatment filtration technology solutions. All industrial water purification systems for sale are produced to ISO 9001 quality standards, with additional accreditation to meet the specific requirements of industry sectors such as food and beverage, pharmaceutical, and chemical processing.

Excellent also customizes filtration solutions for Aerospace Filters, Nuclear Filters, Oil and Gas Filtration, and Food and Beverage Filtration.

Industrial Water Filter Applications

Benefits Of Industrial Water Purification System

Increasing the process efficiency

The process efficiency can be remarkably increased through industrial water filtration. In this process, we use the recycling and reusing of water from Waste streams and make it used for drinking and other purposes.

Reduced maintenance costs

Industrial filtration is on an industrial scale and has a long service life. It is beneficial in removing the harmful contaminants from the water. For this purpose, you must purchase equipment that reduces maintenance costs.

Low energy cost

Now you can easily save money on energy costs using the new filtration systems. Many industries use different processes for the use of wastewater with the help of local water treatment facilities. However, companies are struggling a lot to explore different ways of filtering water.

Industrial Water Filter Types

1. Basket or pipeline strainers

In this water filtration system, you can collect the contaminants by using a perforated plate screen or mesh screen. It is a type of closed water filtration system, and when you think the screen is full, Then you must take it out and clean it before use. So we can say that these closed vessels are called strainers, and they collect all the solid particles when the fluid passes through them. This removable screen is called an industrial strainer basket.

2. Automatic self-cleaning strainers

This process usually uses the system pressure to clean the water. As the name depicts that it is a self-cleaning filtration process, it uses a rigid cylinder screen that strains all the particles of the water source. So you can easily trap all the debris inside the strainers. It works on the difference of pressure across the inlet and outlet. The cleaning apparatus eradicates build up from the screen and then throw it out.

3. Bag filter

Bag filters are industrial filters that work like coffee filters. They can trap the solid particles or any type of particle in the water that passes through that filter.

4. Reverse osmosis

As I also discussed earlier, reverse osmosis is the most popular and accurate water filtration system. Although it is costly, it will give you effective results. It is therefore called reverse osmosis in which the water is filtered to a high extent. A semipermeable membrane is used in reverse osmosis which is a heavy-duty water filtration system that can easily remove all the contaminants from the water.

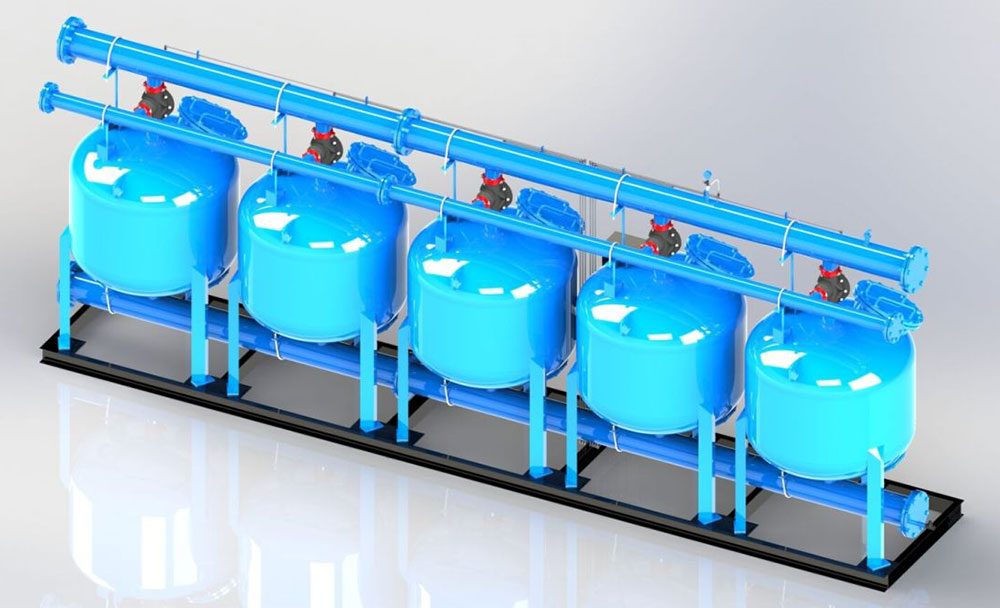

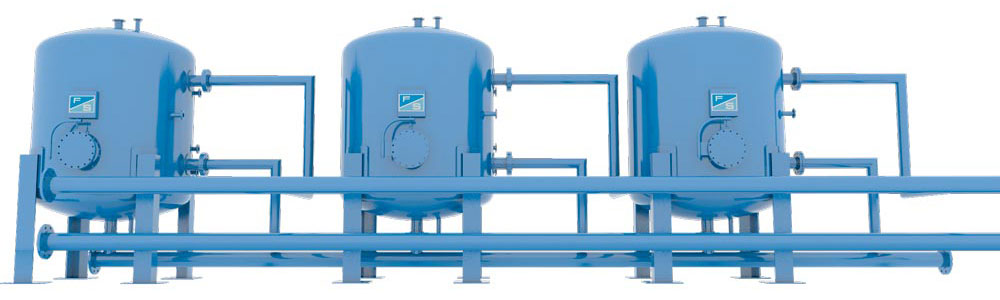

5. Media filters

Media filters are somewhat different than the other types of filters described above. In media filters, different types of filters are used which are arranged in the form of layers. So when different types of materials pass through these layers of filters.

What Factors To Consider Before Purchasing An Industrial Water Filter Machine?

You can see many types of filters present in the market. But keep in mind that different filters have different abilities. Other filters though have some limitations to some extent. You must consider different factors according to the demands of the application system.

Level of contamination

You must check the level of contamination of your water. The reason is that if there is a high amount of solid impurities, then you have to use the pre-filters. Also, you will have to do frequent cleaning and replacement of filters if your water is heavily polluted.

Types of filtration

There are many types of filtration processes from which you can choose according to your choice and convenience.

- Many filtration systems require continuous filtration.

- Many application systems continuously move the work unit without a break. These systems are also included in continuous filtration.

- In some filtration processes, you need the given amount of water at a time to be filtered. These are called batch applications. Keep this thing in mind that you can use simple filters in batch filtration processes.

Quality standards for filtration

The quality of the water is very much important that you get after the filtration process. Also, it’s quality will determine the types of filters you need for your operation. Keep this thing in mind that if you want filtered water for human consumption, then your filter must have the ability to eradicate heavy metals, pathogenic bacteria, and other hazardous products.

Operation conditions and requirements of your process

Keep in mind all the operational requirements that match your filters. You must be aware of the pressure-flow rate and temperature of your filtration process. Keep in mind that every screen has maximum operating temperature and pressure as well as flow rates. So you must go for the high-pressure filtration system because low flow rates will tremendously slow down your operations. Along with the low pressure, the low working temperature will also break down and shut down the process.

Nature and characteristics of the contaminants

While using any filtration system, you must be aware of the nature and characteristics of the contaminants present in the water. For this purpose, you should know about the size and type of the impurities you need to filter out. There is a massive difference between solid and liquid contaminants. The main focus is on determining the pollutants that are harmful to your health. For this purpose, you must need specialized support equipment and installation to ensure the protection of human health.

The operation cost of filters

Before purchasing any type of water filtration system, you must enquire the initial cost of the screen as well as other operational expenses. Other expenses include replacement and installation costs. Along with it, you must also consider the downtime cost and waste disposal cost.

Get A Free Quote

If you need a complete filtration solution, Excellent Industrial Filter Supplier will help you.