Metal Fiber Filter Bag for Alumina Plant

The menace of smog is a clear sign of air pollution and has brought the issue of atmospheric pollution to the forefront of global attention. This heightened awareness has led to a strong demand for stricter environmental emission standards, especially for industries known for their large pollution footprint, such as alumina plants. These facilities, which are an integral part of aluminum production, are now under the microscope and are responsible for implementing strict pollution control measures. The need to reduce pollutants has never been more important than it is now in areas with intensive development or where the ecological balance is fragile. With the growing call for environmental protection, the regulatory environment has become increasingly stringent, casting a wider net in areas that require strict emission regulation.

Metal Fiber Bag Dust Collector Principles

In the complex processes of an alumina plant, the role of metal fiber bag dust collectors is a key component in maintaining environmental compliance and operational efficiency. The operation of the system is a testament to engineering innovation, blending physical and mechanical principles to achieve superior dust control.

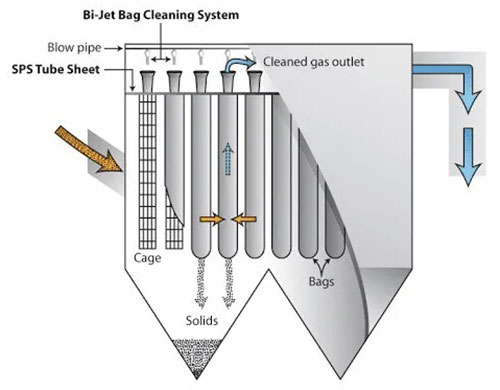

When dusty gases enter the dust collector from the intake duct, they begin a journey through a carefully designed system designed to maximize dust capture while minimizing resistance. Initially, the larger and denser dust particles succumb to gravity and settle in the hopper located at the bottom of the unit. This gravity-based separation acts as a first line of defense, effectively reducing the load on subsequent filtration stages.

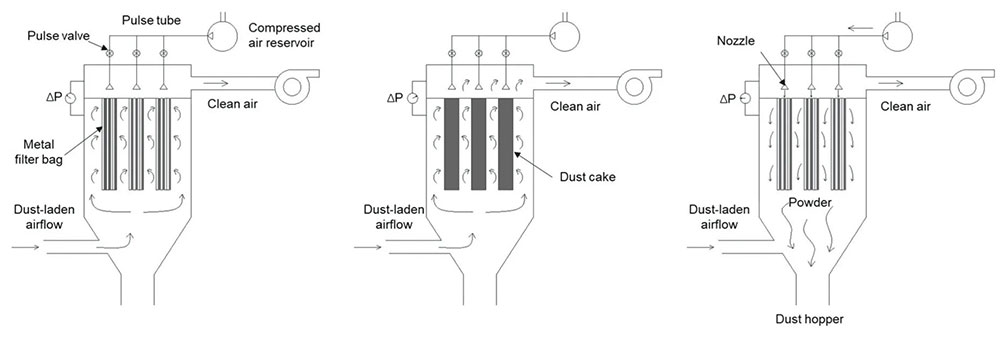

The finer, lighter particles that escape the initial capture enter the baghouse, where the true finesse of metal fiber bag filters is demonstrated. Here, a variety of forces, from inertia and collision to screening, interception and electrostatic attraction, work together to ensure that these elusive particles adhere to the surface of the metal fiber filter bags. This multi-layered approach to filtration highlights the system’s ability to handle a wide range of particle sizes and types, ensuring thorough purification of the airstream.

The purified gas then enters the clean air plenum and is ultimately discharged through the outlet duct, leaving emissions that are significantly cleaner than when it was initially introduced. However, the process does not end with filtration. The system’s efficiency is maintained through periodic cleaning cycles triggered by time or pressure differentials. When the layer of dust on the filter bags reaches a critical thickness, causing an increase in resistance, the dust collector’s pulse cleaning system is activated. A rapid, powerful burst of compressed air is blasted into the bags, dislodging the accumulated dust and causing it to fall into a hopper below. This pulse jet cleaning method is essential to ensuring the longevity and effectiveness of the filtration system, allowing for continuous operation without frequent human intervention.

The collected dust is now removed from the filter bags and conveyed out of the system by the dust removal system, ensuring a clean closed loop process. This final step in the dust collector’s operation not only marks the efficiency of the system’s dust removal, but also highlights its contribution to the overall sustainability of plant operations.

In essence, the metal fiber bag dust collector is a beacon of modern dust control technology. Through a clever combination of gravity settling, sophisticated filtration mechanisms and highly efficient cleaning cycles, it ensures alumina plant meet stringent environmental standards while maintaining operational efficiency, ushering in a new era in industrial dust control.

What role do metal fiber filter bags play in reducing emissions from alumina plant?

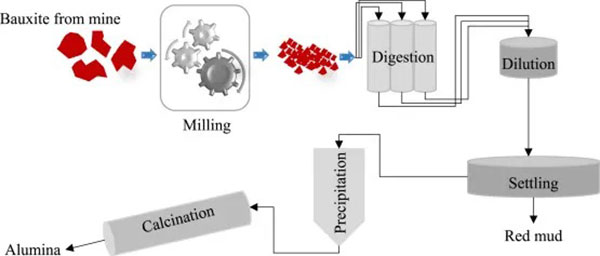

The routes to produce alumina include the alkaline process, the Bayer process, the sintering process, and the combined process are the main methods. These processes depend on the nature of the bauxite, and the calcination of aluminum hydroxide is a key stage in the production process. This stage mainly produces high-temperature flue gas, mainly from the Venturi dryer. The established strategy to maximize waste heat includes the hot flue gas flowing countercurrent to the aluminum hydroxide, facilitating the drying and calcination processes. This process not only optimizes the use of heat, but also ensures the separation of the treated alumina from the gas in the hot separator. After heat exchange and dust purification, the cooled gas is released to the atmosphere through an emission control system.

Historically, the burden of managing these emissions has fallen on electrostatic precipitators, which are capable of handling large volumes of flue gas with controlled emission concentrations. Although these systems are effective, the high operating costs, variable efficiency and space limitations of retrofitting these systems pose a huge challenge, especially in the context of increasingly stringent dust emission standards. The search for solutions to consistently keep particulate emissions below 10mg/m3 has led to a rethinking of traditional approaches, especially considering the unique challenges posed by the flue gas of aluminum hydroxide calciners.

This dilemma is exacerbated in situations where gas temperatures soar beyond the normal operating range, making traditional dust collection technologies ineffective due to the risk of damage caused by transient or sustained high temperatures. This is where the potential of metal fiber filter bags lies, a viable solution that can meet these challenges head-on. Known for their high temperature resistance, corrosion resistance and excellent filtration accuracy, these filter bags are expected to revolutionize emission control in alumina plant. They offer the dual benefits of maintaining operational integrity under extreme conditions and achieving ultra-low particulate emissions, thereby complying with evolving environmental requirements and reinforcing the industry’s commitment to sustainable operations.

The characteristics of the metal fiber bag filter system are multifaceted:

- The system is a combination of electrostatic and bag filtration technology that utilizes the high efficiency of electrostatic dust collection and the high precision of bag filtration. This combination ensures reliable technology with a resistance of no more than 1000Pa.

- Its ability to operate effectively for a long time regardless of flue gas characteristics makes it unique. The system excels in capturing fine and ultrafine particles, always keeping emission concentrations below 10 mg/m3. This level of performance highlights its effectiveness and stability.

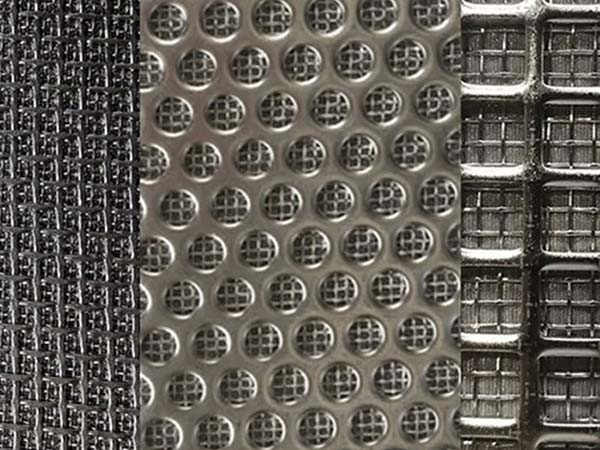

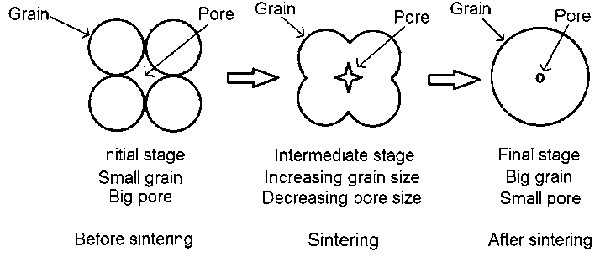

- The use of innovative metal fiber filter bags is resistant to high temperatures and corrosion, providing high filtration accuracy, low operating resistance, extended service life and the possibility of regeneration. The unique dust accumulation structure on the filter surface facilitates cleaning, extends the cleaning interval, and helps to extend the life of the filter bags.

Get A Free Quote

If you need a complete filtration solution, Excellent Industrial Filter Supplier will help you.