10 main functions of porous sintered metal powder

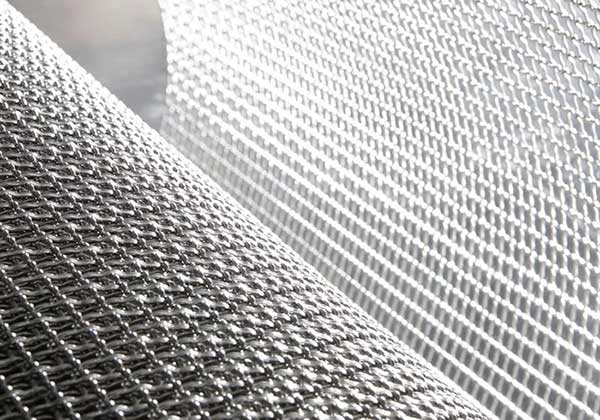

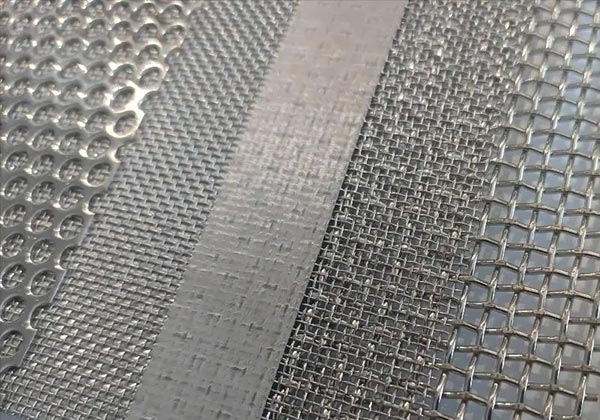

Porous sintered metal powder represents an extraordinary achievement in the field of materials engineering, which integrates the elasticity of metals with the unique characteristics of porous structures. This material is made through a process called sintering, during which small metal powders are melted at high temperature and high pressure, but not completely melted.

This technology can prepare a material with an interconnected pore network, which has controllable permeability and high surface area, while maintaining the inherent strength and durability of the metal. Porosity can be precisely adjusted during the manufacturing process to meet specific requirements for various applications.

Porous sintered metal powders are becoming increasingly important in various industries due to their unique properties. It has excellent high temperature resistance and corrosion resistance, making it an ideal choice for harsh working environments. Due to its porous nature, its filtration and separation capabilities are highly respected in fields such as petrochemicals, pharmaceuticals, and environmental technology.

In addition, its application in fields such as gas diffusion and fluidization has opened up new horizons for industrial innovation. This material is not just a component, but also a proof of progress in materials science. Its increasing relevance in multiple industrial fields reflects its multifunctionality and ability to improve efficiency.

The main function of porous sintered metal powder

Filter Function

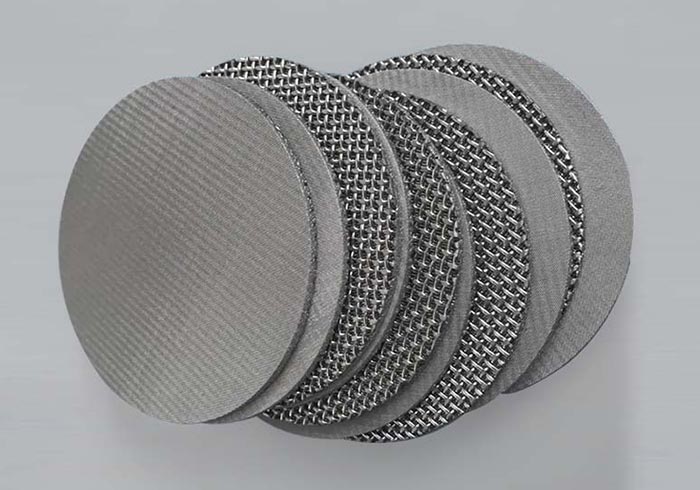

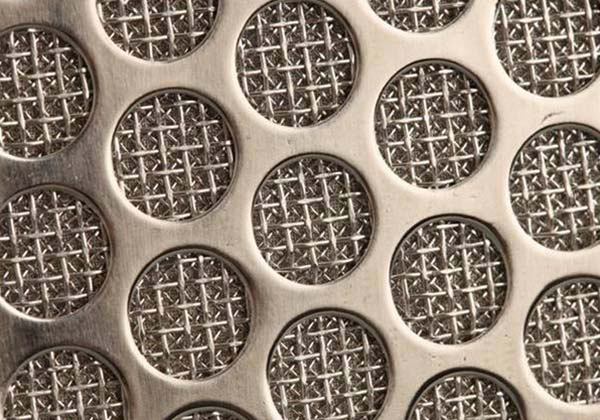

Porous sintered metal powders are widely used due to their filtration performance. Its controllable porosity can accurately separate particles in the fluid, making it an ideal material for efficient filters. Its pore size and distribution can be customized according to specific particle sizes, ensuring effective filtration in various industrial applications. From purifying water to filtering gases in chemical processes, its sturdy structure can withstand harsh conditions and maintain integrity and performance for a long time.

Hot Swap Capability

Porous sintered metals play a crucial role in heat exchange systems due to their excellent thermal conductivity. It is suitable for both refrigeration and heating applications, and its porous structure facilitates efficient heat transfer. This feature is particularly suitable in compact heat exchangers, especially in situations where space is limited but performance requirements are extremely high. In addition, its excellent durability and heat stress resistance make it the preferred choice for such systems.

Energy Absorption Function

Porous sintered metals have efficient energy absorption and dissipation properties. This characteristic makes it an ideal choice for impact absorption and shock absorption applications. Its internal porous structure absorbs energy like a sponge, reducing the impact and vibration effects of mechanical and automotive components, thereby improving performance and extending the service life of these systems.

Mute Function

The soundproofing performance of porous sintered metals is excellent, especially in industrial machinery and automotive components. Its porous structure can effectively absorb sound waves, reduce noise levels, and create a safer and more comfortable working environment. This function is particularly important in environments with severe noise pollution.

Moisture Absorption and Sweat Wicking Function

Porous sintered metals exhibit excellent core-shell properties due to their capillary action. This makes it suitable for applications such as heat pipes and humidity control systems. This material can efficiently transport liquids and help achieve optimal thermal management and humidity regulation for various industrial and electronic devices.

Pressure Control Function

In industries that require precise pressure management, porous sintered metal powders have been proven to have immeasurable value. The ability to regulate pressure within the system is crucial, especially in pneumatic and hydraulic applications. The uniformity and consistency of its porous structure can achieve a reliable and controllable pressure environment, thereby ensuring the safety and efficiency of these systems.

Spray Function

Porous sintered metals are widely used in spray applications, and their controllable porosity can effectively introduce gases into liquids. This feature is crucial in the chemical processing and brewing industries, as it enhances aeration, fermentation, and other processes. The corrosion resistance and high temperature resistance of this material make it an ideal choice for these applications.

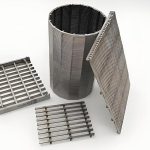

Fluidization Function

Porous sintered metals are crucial for mixing, drying, and coating processes in fluidized beds. It can evenly distribute gas through pores, forming an effective fluidized medium, thereby improving the efficiency and uniformity of these processes. This function is crucial in the pharmaceutical, chemical, and food processing industries.

Catalytic Function

Porous sintered metals are excellent substrates for catalytic applications. Its high surface area and high-temperature stability make it suitable for processes such as emission control and chemical synthesis. The durability and resistance to chemical degradation of this material ensure its long-term effectiveness in these critical applications.

Electromagnetic Shielding Function

Porous sintered metal powders are crucial for shielding electromagnetic interference in electronic and communication devices. Its ability to absorb and deflect electromagnetic waves can protect sensitive equipment from interference and ensure its reliable performance. In the era where electronic devices are ubiquitous and susceptible to electromagnetic interference, this function has become increasingly important.

Porous sintered metal powder is a widely used material that plays a crucial role in many industries. It has a wide range of functions, from effective filtering and heat exchange, to energy absorption, sound attenuation, and electromagnetic shielding. These characteristics make it play an immeasurable role in applications such as advanced cooling systems, mechanical shock absorption, and protective measures for electronic devices. Its versatility has been fully demonstrated in various fields, which helps to improve efficiency and safety.

The future potential of porous sintered metal powder is unlimited. With the continuous development of technological demand, this material is expected to play a key role in emerging fields and green energy solutions. The ongoing research is expected to further improve its performance and explore new applications. This continuous innovation is in line with the Sustainable Development Goals, consolidating its position as a key component of industrial technological progress, symbolizing the advancement of materials science and the enormous potential for industrial development.